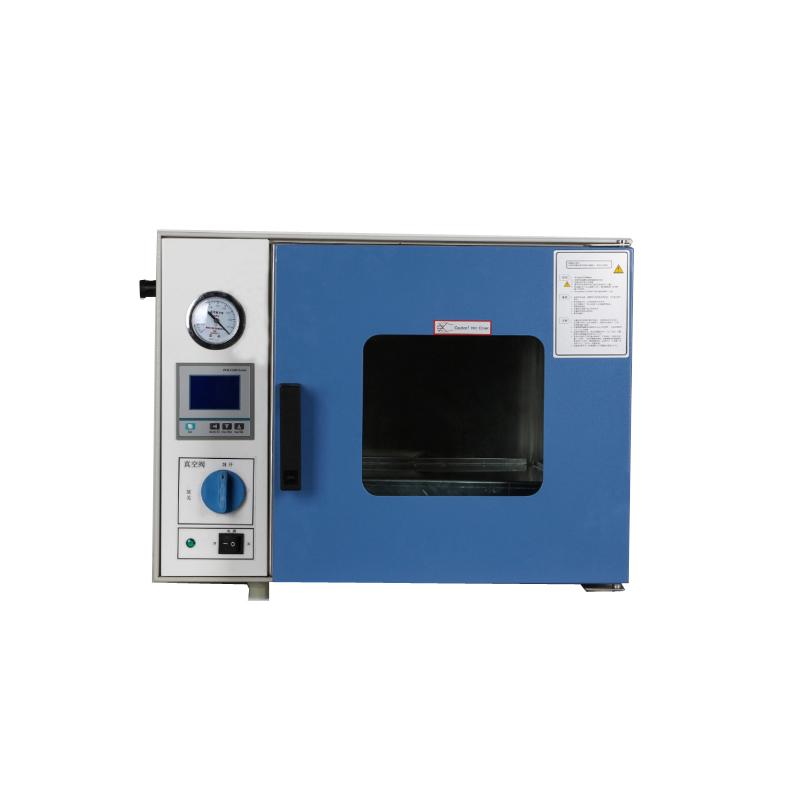

MODERNER ZGX-6053 Vacuum Oven temperature control RT + 10~250 ℃

Moderner ZGX-6053 Vacuum OvenSPEC

Moderner ZGX-6053 Vacuum OvenDetails

Moderner ZGX-6053 Vacuum OvenPacking list

- SKU

- NB018830

- Power

- 220V AC 50HZ

- Temperature range

- RT+10~250℃

- Temperature Fluctuation

- ±1℃

- Temperature Resolution

- 0.1℃

- vacuum

- ≤133Pa

- Input Power

- 1200W

- Interior size

- 415*370*345mm

- Dimensions

- 830*640*540mm

- Shelf (std.)

- 2pcs/3pcs

- Chamber material

- stainless steel

- Timer

- 1~9999Min

Overview

It is widely used in biochemistry, chemical industry, pharmaceuticals, agricultural scientific research, environmental protection and other research and application fields, and is used for powder drying, baking and disinfection and sterilization of various types of glass containers. It is especially suitable for rapid and effective drying of items that are heat-sensitive, easily decomposed, easily oxidized and have complex components.

Advantages of vacuum drying technology

The vacuum environment greatly reduces the boiling point of the liquid that needs to be expelled, so vacuum drying can be easily applied to heat-sensitive substances;

For samples that are difficult to dry, such as powder or granular samples, vacuum drying can effectively shorten the drying time;

Vacuum drying is used for various mechanical parts with complex structures or other porous samples after cleaning, and no participating substances will be left after complete drying;

Safer to use - under vacuum or inert conditions, completely eliminating the possibility of oxides exploding when exposed to heat;

Compared with ordinary drying that relies on air circulation, the powdered sample will not be blown or moved by the flowing air.

Features

â The heating element is located on the internal partition of the box, which shortens the heating time by 50% compared with traditional vacuum Drying Ovens (except for 6050, 6050B, and 6051).

â Large-screen LCD display, multiple sets of data displayed on one screen, menu-based operation interface, easy to understand and operate. (optional)

â The aluminum shelves are stamped using a special process, which is non-oxidizing at high temperatures and has fast thermal conductivity. Reduce heat loss as much as possible.

â The cuboid working room ensures high effective volume utilization, and the microcomputer temperature controller ensures accurate and reliable temperature control.

â Toughened, bullet-proof double-layer glass door allows you to observe objects in the studio at a glance, and can fill the interior with inert gas.

â The closing tightness of the box door can be adjusted by the user at will, and the integrally formed silicone rubber door seal ensures high vacuum in the box.

â The working room is made of stainless steel plates, and the outer shell of the box is made of high-quality cold-rolled steel plates, with the surface electrostatically sprayed.

â Storage, heating, testing and drying are all carried out in an environment without oxygen or filled with inert gas, which will not cause oxidation.

Optional

Intelligent program controller

Large screen LCD monitor

Inert gas inlet valve

Gas-liquid separator

Vacuum drying tank

Cabinet(6020/6030/6050)

Vacuum pump-2XZ-2

Vacuum pump-2XZ-4

ZGX-6053

ZGX-6053