JFL QFH-S600 adhesion plate (guide grid)

SEJFL QFH-S600 Adhesion hundred grid plate (guide grid)SPEC

JFL QFH-S600 Adhesion hundred grid plate (guide grid)Details

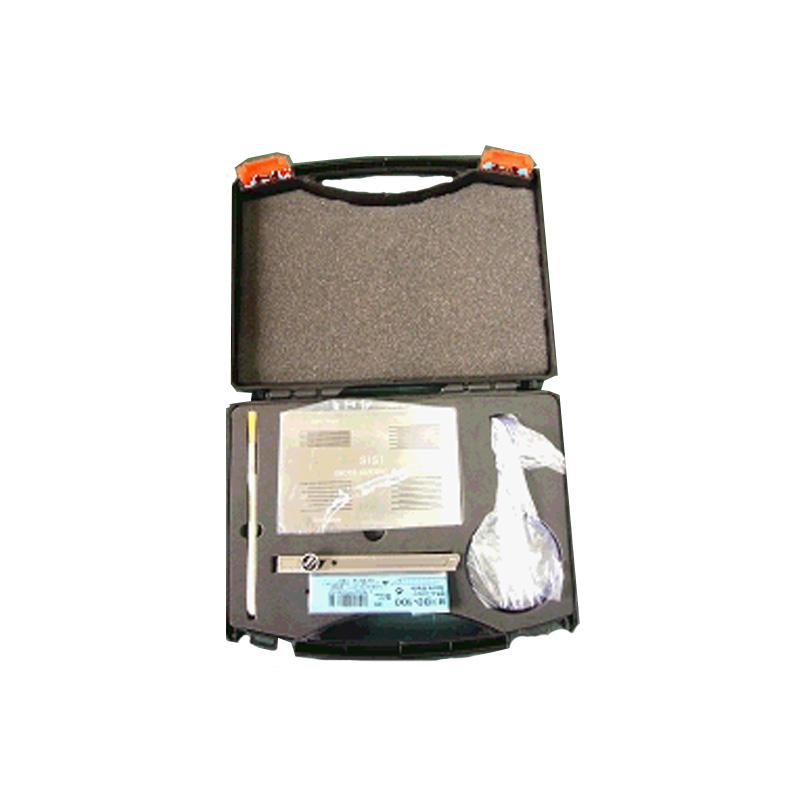

JFL QFH-S600 Adhesion hundred grid plate (guide grid)Packing list

- SKU

- NB019011

- Tooth spacing

- 1mm、1.5mm、2mm、3mm

- Cut length

- 35mm

- Number of cuts

- Article 11

Introduction

use

The instrument is mainly suitable for the determination of the cross-hatch adhesion of organic coatings. It is not only suitable for laboratories, but also can be used for construction sites under various conditions.

Principle and Application

The instrument cuts and penetrates the coating as a lattice pattern with a tool of a certain specification, and the completed pattern is classified into six grades to evaluate the adhesion effect of the separation of the coating from the substrate.

1. It is suitable for measuring the adhesion strength of the paint film on the surface of plastic and wooden furniture with a thickness of less than 250mm on the substrate.

2. It is suitable for the strength of adhesion on the surface of sprayed or electroplated products or the strength of the combination of primers and topcoats.

Operation method

1. The test piece needs to be prepared according to the provisions of ISO1514 and ISO2828.

2. Place the test piece on a flat plate with sufficient hardness.

3. Hold the guide gauge (100-grid board) so that the bottom surface is completely flat with the surface of the surface coating.

4. Use uniform force to suppress the 100-grid board, and use a sharp-edged knife to cut and cut at a cutting speed of 20-50mm/S.

5. Rotate the grid board 90 degrees, and repeat the above operations on the cuts to form a grid pattern.

6. Use a soft brush to clean off the scratched dross and use the grid pattern on the surface of the test piece.

7. Stick the tape that meets the standard on the scratched surface and tear off the tape to observe the coating adhesion strength on the surface.

Precautions

1. All cuts should penetrate the coating, but not too deep into the substrate.

2. If the coating is too thick and hard to penetrate the substrate, the test is invalid, but it should be stated in the test report.

3. The test tape needs to be 610-1PK test special tape produced by 3M Company in the United States. Stick the adhesive tape on the entire grid, and then tear it off at the smallest angle. The result can be obtained according to the ratio of the glued area on the surface of the paint film.

4. The test should be carried out at a temperature of 23±2°C and a Relative Humidity of 50±5%.

- 1JJF 2163-2024《Calibration Specification for Paint Film Scribers》

- 2NF 《Paints and varnishes - Cross-cut test》

- 3GB/T 13217.7-2023《Test method for adhesion to substrate of ink with tape》

- 4GB/T 4893.4-2023《Test of surface coating of furniture—Part 4:Determination of adhesion by cross-cut》

- 5GB/T 42541-2023《Coated steel pipes for gas piping》

- 6HG/T 2006-2006《Thermosetting powder coatings》

- 7GB/T 9286-2021《Paints and varnishes—Cross-cut test》

- 8HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 9HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 10HG/T 5187-2017《Automobile axle spring anticorrosive primer》

QFH-S600

QFH-S600