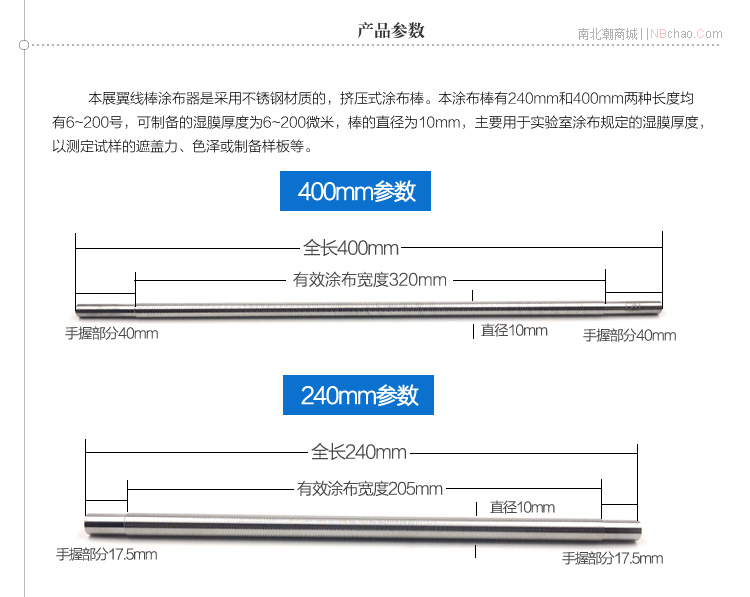

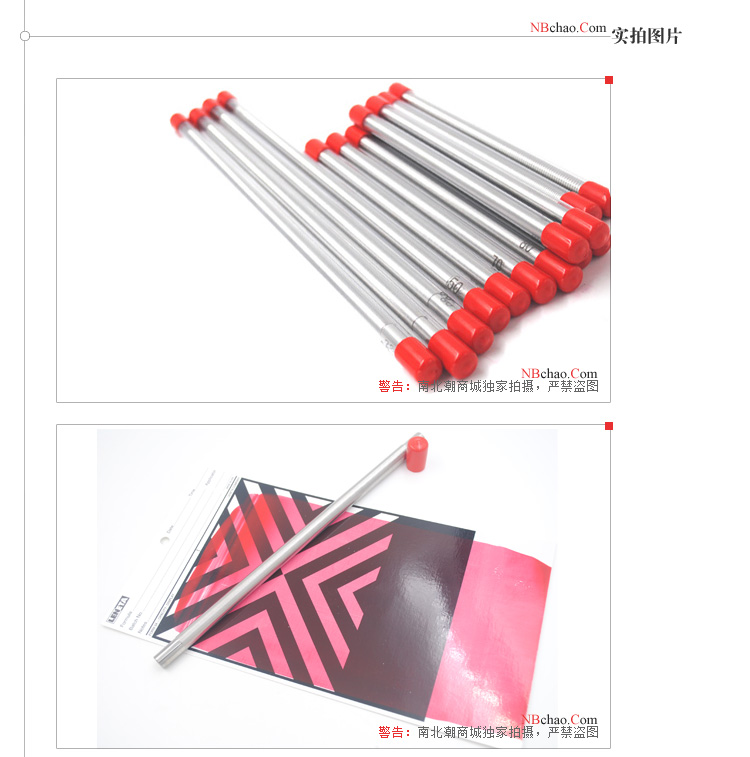

ZHANYI No. 10, Spreader coating bar length 240mm film thickness 10μm

SEFormed, wet film thickness 10μm, diameter 10mm, Total length 400mm, application width 205mm, hand width 17.5 + 17.5mm, material stainless steel.

Model:

Similar products

ZhanYi ZY-10/240 Mayer RodSPEC

ZhanYi ZY-10/240 Mayer RodDetails

ZhanYi ZY-10/240 Mayer RodPacking list

- SKU

- NB000191

- Production process

- Formed

- WFT

- 10µm

- diameter

- 10mm

- Total length

- 400mm

- Application width

- 205mm

- Grip width

- 17.5+17.5mm

- material

- stainless steel

ZY-10/240

Mayer Rod

Formed, wet film thickness 10μm, diameter 10mm, Total length 400mm, application width 205mm, hand width 17.5 + 17.5mm, material stainless steel.

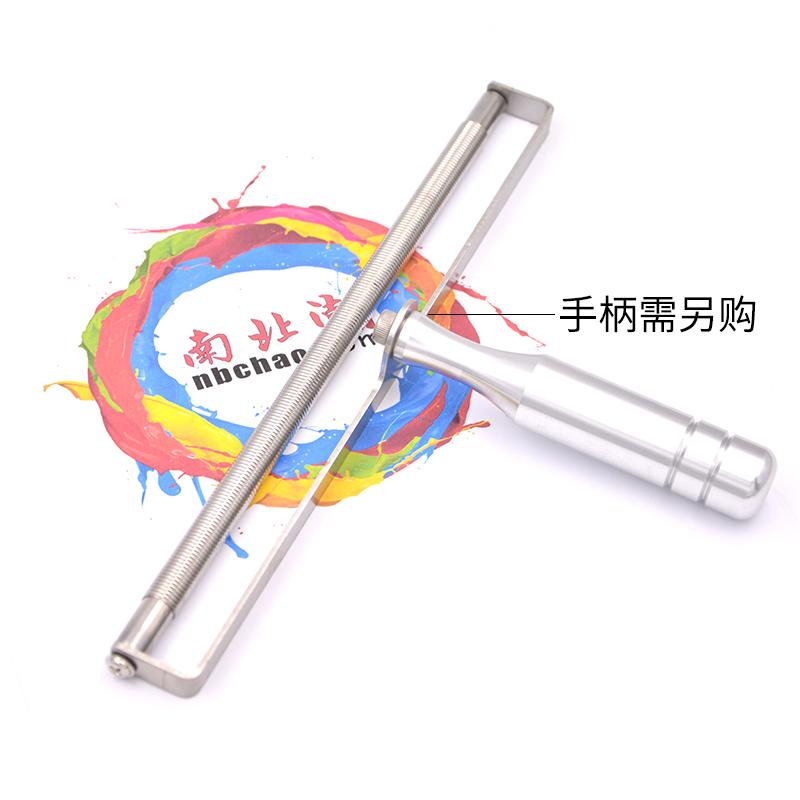

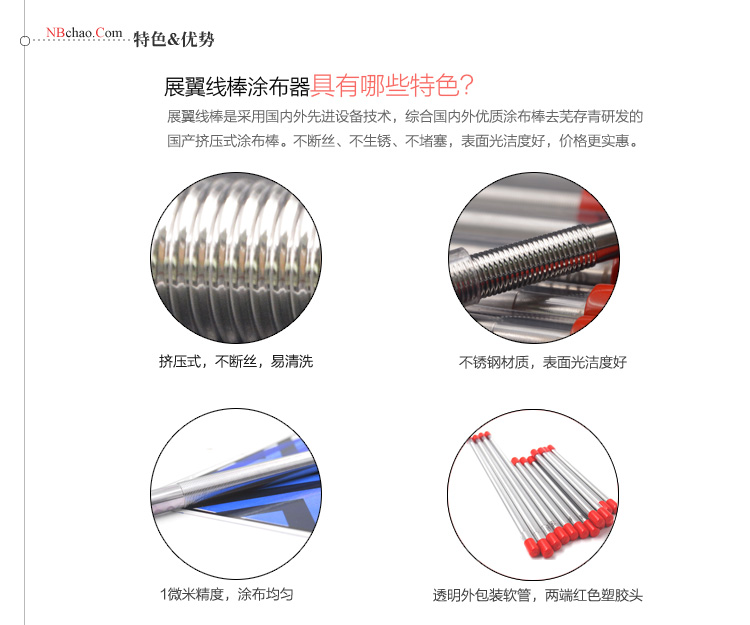

Zhanyi No. 10 coating bar is used to prepare a wet film with a thickness of 10 microns for the test of the film thickness requirement to measure the corresponding performance of the coating film. Zhanyi wire rod is a coating rod that introduces foreign professional technology and processes steel rods into continuous grooves through a special extrusion process. It can achieve the same film-making effect as the wire-wound coating rod, and it has continuous wire, The advantage of not being easy to clog paint impurities makes it more satisfying the needs of some users, and the advantage of high cost performance makes it gradually increase its influence in CHINA.

Optional

FAQ

QCan ZHANYI ZY-10/240 Mayer Rods meet the GB/T13217.1 standard?

A

Applicable, you can consult the customer service of the mall for details about the GB/T13217.1 standard.

QIs it feasible to prepare PTFE/PP composite diaphragm with Mayer-Rod?

A

Yes, by diluting to a reasonable PTFE emulsion, Stir a suitable binder uniformly, a single-layer film is prepared on the PP film, and after the composite diaphragm is initially dried, it is placed in a 60 ° C constant temperature bellows for drying, and the solvent evaporates. It is worth PTFE/PP composite diaphragm.

QThe solid content of the paint is 25%. If you want to scrape the ink and dry 3 microns, can this be done?

A

Can be done

Standard

ZY-10/240

ZY-10/240