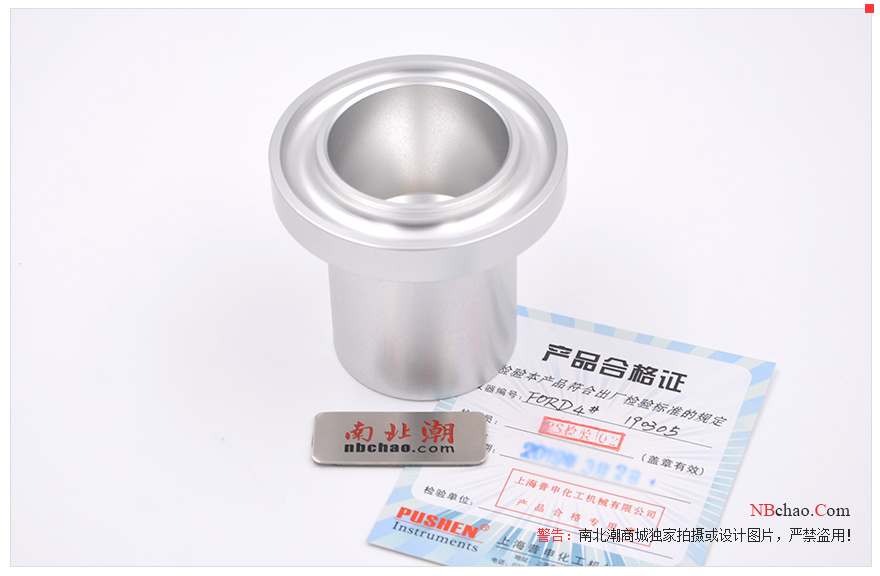

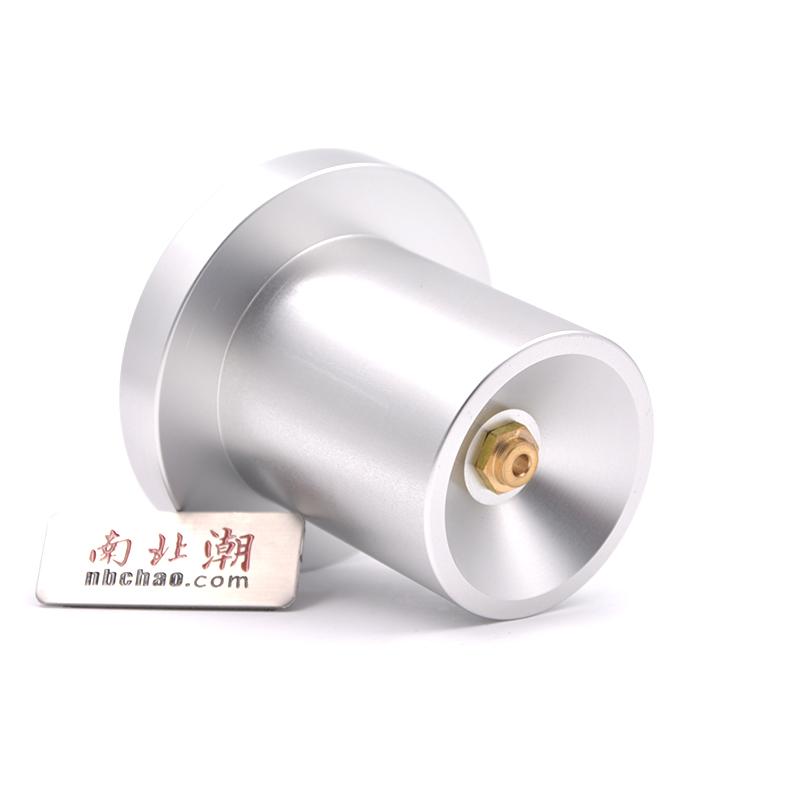

Pushen Ford-3 #Ford Viscosity Cup Aluminum inks Viscosity Cup

SEPushen Ford-3# Ford Viscosity CupSPEC

Pushen Ford-3# Ford Viscosity CupDetails

Pushen Ford-3# Ford Viscosity CupPacking list

- SKU

- NB019429

- Viscosity range

- 49~220cSt

- outflow time

- 25~105s

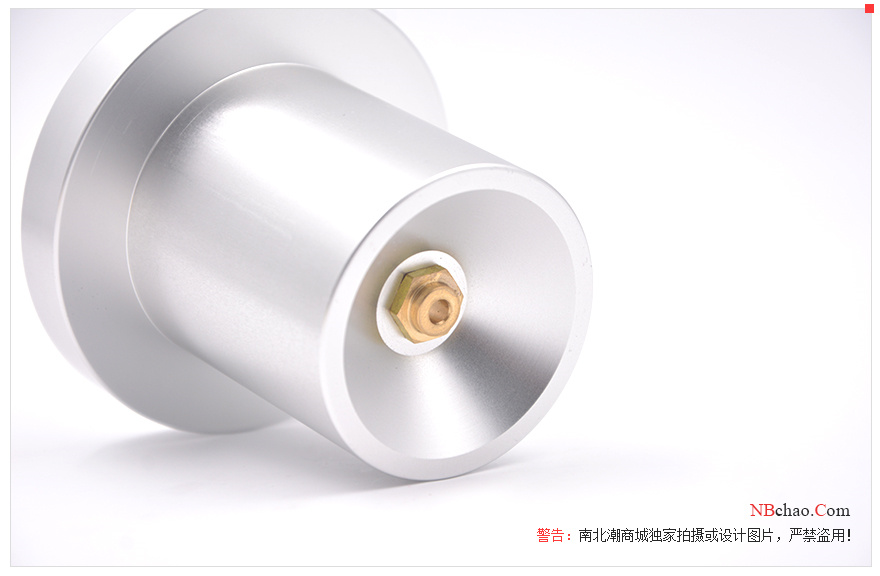

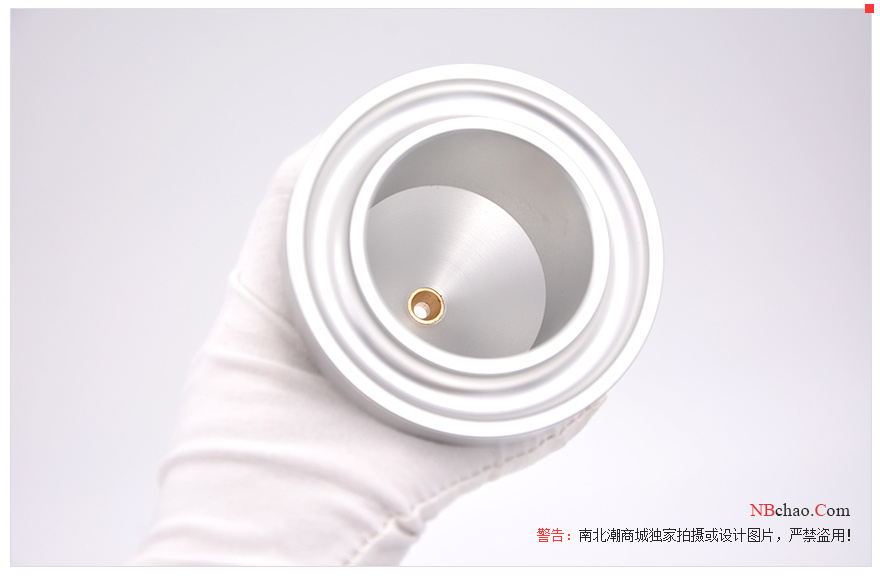

- Flow hole diameter

- 3.4mm

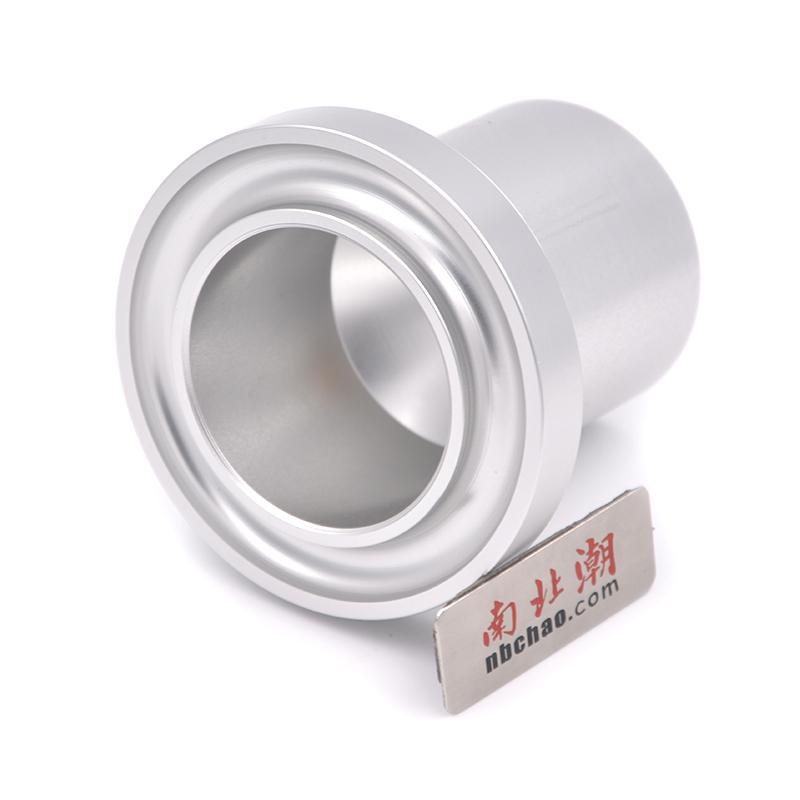

- Capacity

- 100ml

- Cup height

- 87mm

- Cup width

- 55mm

- Cup body material

- Aluminum cathode oxidation

- Filter material

- Brass

- Applicable standard

- ASTM D1200

- Environment temperature

- 23±0.2℃

- Certificate

- without

- Weight

- 292g

The Ford (Ford) cup is made according to ASTM D 1200, D333, D365 of the American Society for Testing and Materials paint and raw material standards. It is a convenient viscometer for measuring the viscosity of inks, coatings, paints, etc. It is crafted from a good aluminum cup with a small hole in the bottom and a capacity of about 100ml.

The Ford (Ford) cup measures the viscosity of the sample by measuring the time required for a certain volume of the sample in the aluminum cup to flow out of the small hole at the bottom.

Equipment and Utensils

1. Stopwatch: Accuracy 0.1 (self-provided)

2. Ford cup holder (optional)

Instructions

1. Before use, use a suitable solvent to wipe the inner wall of the cup (note: please pay special attention to cleaning the small hole of the cup, twist it into a rope with soft paper, and pull it repeatedly in the outflow hole); then dry it in the air or Blow dry with cold air, and do not allow any residual liquid from the past measurement liquid to adhere to the cup or the outflow port.

2. Select an appropriate cup number to control the outflow time between 20 and 80 seconds (see Specifications)

3. Stir the test solution evenly, filter it in a sieve with no less than 567 holes/square centimeter, and adjust the temperature of the sample and the outFlow Cup to (23±0.5°C) or another agreed temperature

4. Adjust the Ford cup bracket to make the upper horizontal bubble center.

5. Pour the sample into the Ford cup, and block the outflow hole with a finger (if it is a corrosive liquid, you can use a baffle to block the outflow hole). After filling, scrape the cup flat with a metal or glass plate, and remove the excess sample. Scrape the sample into the groove on the edge of the Viscosity Cup, and put the receiving cup in place.

6. Let go of your finger or push the baffle, the sample flows out vertically, and start the stopwatch at the same time. Stop timing when the first breakpoint occurs, and the number of seconds of outflow time at this time is the viscosity value of the sample to be tested.

7. Repeat the measurement three times, and take the average value as the final reading.

8. Immediately clean it with a suitable solvent. Never use metal cleaning tools or wire. If the orifice is soiled with dried deposits, soften it with a suitable solvent and clean it carefully, eg by pulling a soft cloth through the orifice.

Four. Precautions for maintenance

Due to the drop and collision of the Ford Cup, the small hole will be damaged or deformed, resulting in measurement errors, so care must be taken during use.

calibration

1. The instrument should be calibrated regularly after each year of use (the diameter of the orifice has been calibrated in the factory with Newtonian oil that can be traced back to NIST oil before leaving the factory, and the user does not need to calibrate it within one year after purchase)

2. Calibration needs to use standard silicone oil in accordance with the relevant national Viscosity Cup measurement regulations.

other

The results obtained for a particular dipping cup are expressed in "seconds" at a specified temperature. To convert "seconds" to centistokes, see ASTM D 4212.

- 1ASTM 《Standard Test Method for Viscosity by Ford Viscosity Cup》

- 2ASTM D1200-2010《Standard Test Method for Viscosity by Ford Viscosity Cup》

- 3ASTM D5125-2020《Standard Test Method for Viscosity of Paints and Related Materials by ISO Flow Cups》

- 4JJG 743-2018《Flow Cup Viscometers》

- 5ASTM D1200-2018《Test method for viscosity by Ford viscosity cup》

- 6GB/T 2794-1995《Determination methods for viscosity of adhesives》

- 7 《Determination of viscosity with Ford viscosity cup》

- 8JJG 743-1991《Viscometer Flow Cup verification》

Ford-3#

Ford-3#