PUSHEN PM-380V plane grinding machine 380V

SEPushen PM-380V plane grinding machineSPEC

Pushen PM-380V plane grinding machineDetails

Pushen PM-380V plane grinding machinePacking list

- SKU

- NB019540

- Power

- 380V AC 50Hz

- Motor power

- 0.75KW

- Grinding disc speed

- 80cpm

- Grinding disc diameter

- 240mm

- Counting range

- 0~999

- Load Weight

- 0.9Kg 、 1.75Kg 、 1.75Kg 、 2.92Kg

- load pressure

- 27 Kg 、 47 Kg 、 69 Kg 、 102 Kg

- Standards

- GB/T5211、ISO787/16,8780-5、ASTM D322-B,D387

- Overall Dimensions

- 580*368*472mm

- Shipment Weight

- 93Kg

- Electrode speed

- 1440 rpm

- Glass disk speed

- 855 rpm

- Counting range

- 0~999

- Total power

- 0.555Kw

- Number of jobs displayed

- 0-9

Uses and Features

The flat Grinder is the required instrument in the national standard GB5211.19 "Determination of relative tinting strength and diluted color of coloring pigments by visual comparison method".

This machine can be used as a professional physical performance testing instrument for the pigment, paint and ink industries. The whole machine is compact in structure, simple in appearance, easy to change the number of revolutions and loads, and easy to assemble and disassemble the glass plate. Microcomputer control, LCD display, easy parameter setting. When the input parameters are wrong, the controller will automatically display prompt information, and when over-current and phase failure occur, the controller will also display prompt information. The purpose of reliable control and simple operation is achieved.

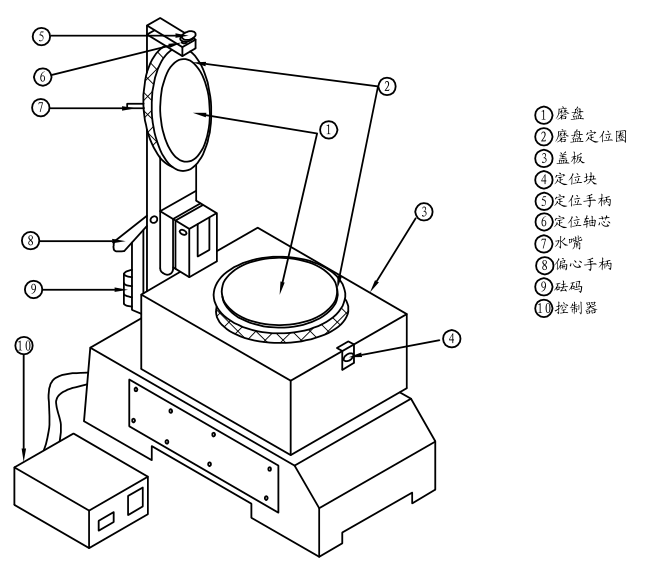

structure diagram

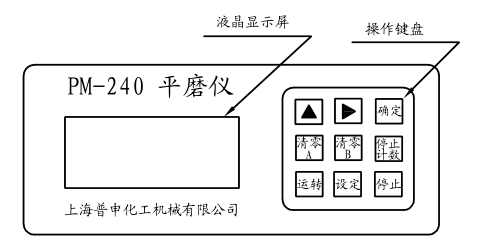

Switch function description

Power key: It is used to switch the main power supply, and it is on when the indicator light is on.

Reset key: used to clear the number of working times. Click to clear the accumulated number of jobs.

Stop key: used for stopping the work, used for stopping and clearing the running times.

Start: It has a pause function, which is used when starting the machine, stopping halfway and needing to keep the count.

Setting key: used to set the number, press the setting key continuously, the sequence is: hundreds digit-tens digit-ones digit-OK, when the corresponding position is pressed, the changed digit will flash, at this time, you can press the adjustment key Adjust the number of settings for this bit.

Adjustment key: It is used to adjust the number of the position selected by the setting key, press the key continuously, and it will change from 0 to 9 in turn.

Stop counting key: It is used to run the equipment without counting, press once to stop counting, press once to count.

indicator light

When it is on: it means that the machine is in working state, and it cannot be set at this time.

When it is stopped, it means that the machine is in the state of stopping.

When the setting is on: it means that the machine is in the setting state, and it cannot be turned on at this time.

Standards

GB/T 5211

ISO 787/16, 8780-5

ASTM D 322-B, D 387

- 1GB/T 17001.3-2025《Anti-counterfeiting printing ink—Part 3:Thermochromic anti-counterfeiting printing ink》

- 2HG/T 3239-2009《Technical specifications of plane grinding machine》

- 3HG/T 3854-2006《Determination of mobility of pigments》

- 4HG/T 3853-2006《Determination of resistance to heat of dry power of pigments》

- 5GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 6GB/T 7044-2022《Colour carbon black》

- 7ZB ZB N 13002-1987《Technical specifications of plane grinding machine》

- 8QB/T 2025-2013《Offset tin-printing ink》

- 9GB/T 21868.5-2008《Pigments and extenders - Methods of dispersion for assessment of dispersion characteristics - Part 5: Dispersion using an automatic muller》

PM-380V

PM-380V