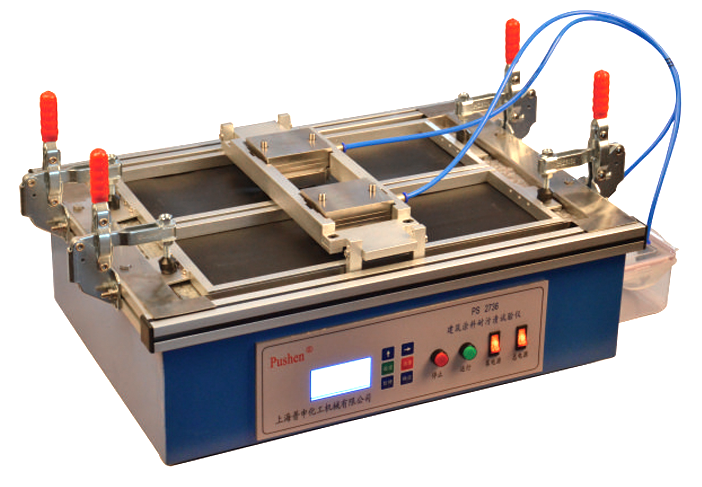

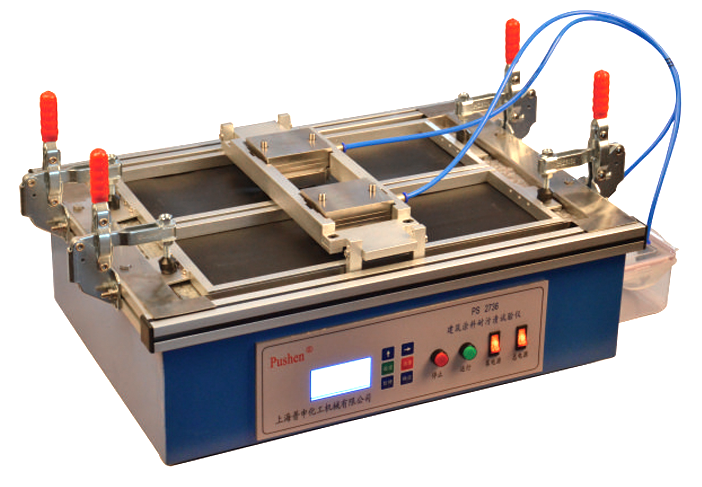

Pushen JTX-II architectural coatings Scrub washability Testers

SE-

JINGKELIAN QFS Coating Washability Tester inter-wall exterior dual-use$ 601.00SE

JINGKELIAN QFS Coating Washability Tester inter-wall exterior dual-use$ 601.00SE -

MODERNER JTX-IV Digital Building Materials Scrub washability Testers

MODERNER JTX-IV Digital Building Materials Scrub washability Testers -

MODERNER JTX-V automatic digitalization scrubber, anti-scrubbing and anti-stain dual-use

MODERNER JTX-V automatic digitalization scrubber, anti-scrubbing and anti-stain dual-use -

JFL QFS Wash Resistance Tester$ 623.00SE

JFL QFS Wash Resistance Tester$ 623.00SE -

HUITAO HT-107 architectural coatings scruf Tester, wet adhesion scruf Tester$ 1669.00SE

HUITAO HT-107 architectural coatings scruf Tester, wet adhesion scruf Tester$ 1669.00SE

Pushen JTX-II Architectural coatings Scrub washability TestersSPEC

Pushen JTX-II Architectural coatings Scrub washability TestersDetails

Pushen JTX-II Architectural coatings Scrub washability TestersPacking list

- SKU

- NB019656

- Brush Specifications

- 38*90mm

- Brush Weight (including brush)

- 450g

- Scrub stroke

- 300mm

- Scrub speed

- 37cpm

- Counter

- 5 digits

- Power

- 220V 50Hz

- Dimensions

- 580*480*300mm

- Machine Weight

- 40kg

The Scrub Tester for Architectural Coatings is an instrument used to evaluate the scrub resistance of coatings. It can also evaluate the performance of any thin-film composite treated surface such as: paint, electroplating, flooring, overlay, wood density and other forms of surface performance. The instrument washes the paint painted on the standard test plate, and the LCD clearly displays the number of times of washing, and the washing resistance of the paint can be evaluated according to the number of times of washing. This instrument is used in conjunction with national standards, and is a verification instrument required by paint manufacturers and paint research departments. This product complies with ASTM, DIN, ISO, GB9266-88.

Painted surfaces need to be tested for scrub resistance by brush or other means.

Subjects tested included: interior paint, wallpaper and carpet.

The Scrub Gauge measures properties related to scrubability and abrasion resistance of coatings.

Accelerated experiments simulating wear and scratches with two brushes.

For comparative testing, brushes, scouring pads, sponges, cleaning cloths, etc. may be used.

A liquid solution for scrubbing in a container next to the instrument can be pumped to the brushes.

During the scrubbing experiment, it can control the opening or closing of the pump, and can accurately adjust the liquid flow.

Instrument Introduction

This product is designed on the basis of summarizing the professional technology of domestic (CN) and foreign models.

1. The machine adopts a professional parallel carriage to keep the brush moving in parallel during the working process, and the weight is constant. It overcomes the card swiping, dropping swiping and swinging phenomena of domestic (CN) models.

2. Adopting a new type of linear reciprocating mechanism, which improves the non-linear reciprocating motion of domestic (CN) models, so that the scrubbing is even in the 300mm stroke.

3. The soap liquid system is automatically circulated by the water pump, which reduces the work of adding soap liquid manually during the operation process in the past, and realizes automatic control.

4. The instrument adopts 64×128 dot-matrix LCD display, which is clear and easy to operate. It can display the dynamic information of the sensor and has the function of data storage and power-off memory.

Standards

GB/T 9755, 9266

ASTM D 2486, 3450

ISO 11998

- 1JJF 001-2015《Calibration Specification for Paint Film Scrub Resistance Testers》

- 2JG/T 512-2017《General technical requirements for building exterior wall coating system》

- 3GB/T 34676-2017《Interior wall coatings for children's room decorating》

- 4HG/T 5065-2016《Finishing varnishes for architectural coatings》

- 5GB/T 9757-2001《Solvent-thinned coatings for exterior wall》

- 6GB/T 9755-2014《Synthetic resin emulsion coatings for exterior wall》

- 7GB/T 9756-2018《Synthetic resin emulsion coatings for interior wall》

- 8ASTM D4828-16《Standard Test Methods For Practical Washability Of Organic Coatings》

- 9ASTM D3450-15《Standard Test Method for Washability Properties of Interior Architectural Coatings》

- 10ASTM D2486-2017《Standard Test Methods for Scrub Resistance of Wall Paints》

JTX-II

JTX-II