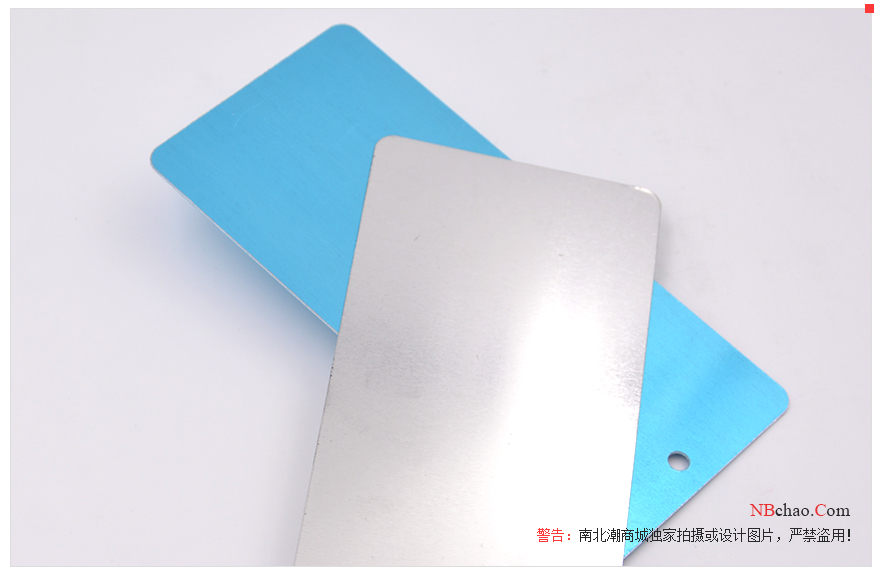

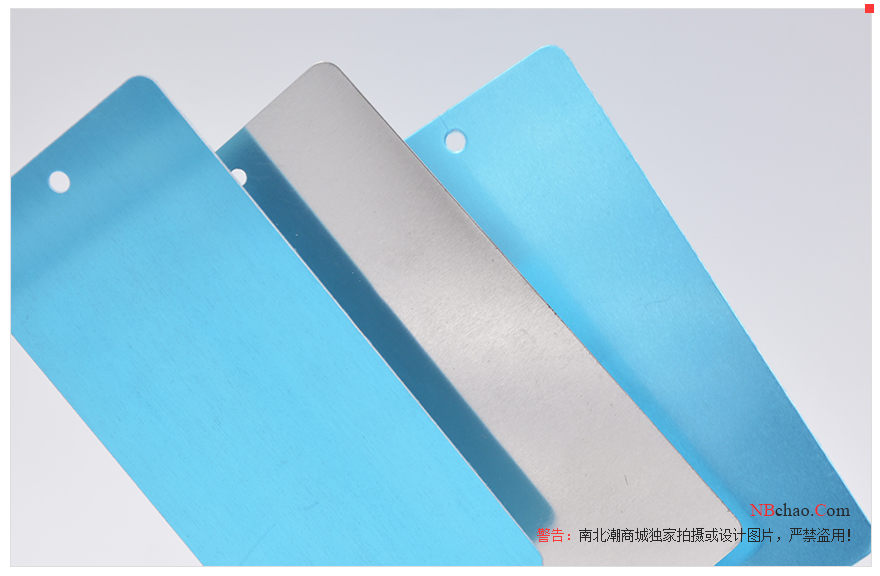

Pushen test grade tinplating capacity E4/120 * 50mm rounded corners non-porous

PUSHEN test grade tinplate is E4, the size is 120 * 50mm, PS 2931/2 test grade tinplate is rounded, the surface is non-porous, in line with GB9271 standard.

Pushen PS 2931/2 rounded corners without holes Test grade tinplateSPEC

Pushen PS 2931/2 rounded corners without holes Test grade tinplateDetails

Pushen PS 2931/2 rounded corners without holes Test grade tinplatePacking list

- SKU

- NB019853

- Length (mm)

- 120

- Width (mm)

- 50

- Thickness (mm)

- 0.28

- corner shape

- rounded corners

- Whether to punch holes

- No

- Tin plating amount

- E4

- Hardness

- T52

- meet the standard

- GB/T 9271

- Encasement

- 100 pieces/pack

PS 2931/2 rounded corners without holes

Test grade tinplate

Test-grade tinplate

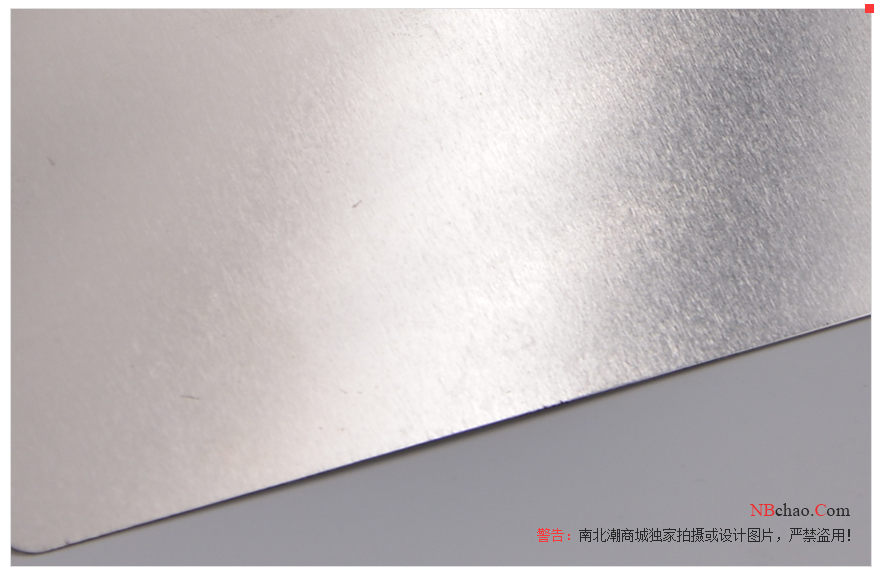

The coating film is required to be prepared on the tinplate during the performance testing (adhesion, hardness, impact, flexibility, bending, drying time) of almost all industrial coatings, and the tinplate surface tin locking, hardness and surface treatment are the most important factors affecting the test results; The test grade tinplate of this series complies with GB2520; The amount of tin is E4, the hardness grade is T52, and the thickness is 0.28mm. The surface treatment is carried out according to the requirements of GB9271.

Serial models

| Model | specification | thickness |

| PS 2931/1 | 120*25mm | 0.28mm |

| PS 2931/2 | 120*50mm | 0.28mm |

| PS 2931/3 | 150*70mm | 0.28mm |

| For special specifications and size customization, please consult the customer service of the North and South Tide. | ||

FAQ

QIs the price listed on the website the final cost for overseas purchases?

ANo, it isn't. This is the ex-factory price of the product in the Chinese Mainland. In addition to this price, buyers from different countries need to account for additional costs such as shipping fees, tariffs, and others. For specific regional quotes, please consult our customer service or fill out a quotation form.

QWhat is the specific process for purchasing the product?

AFirst, please click on the quotation form on the website and fill in detailed information. Our customer service personnel will then send you a quotation based on your specific country and region, confirming payment and delivery methods. Following this, we proceed with contract signing, payment, and shipment. You can then await delivery.

QWhat should I do if the instrument I purchase needs repair?

AAfter-sales repair for overseas instruments is an unavoidable issue. Our repair terms stipulate that the sender is responsible for the shipping and insurance costs incurred for the repair. Repairs within the warranty period are free, while repair costs beyond the warranty period are determined based on the actual situation.

PS 2931/2 rounded corners without holes

PS 2931/2 rounded corners without holes