CNSHP NDJ-1 Digital Rotational Viscometer

hengping NDJ-1 Digital Rotational ViscoMeterSPEC

hengping NDJ-1 Digital Rotational ViscoMeterDetails

hengping NDJ-1 Digital Rotational ViscoMeterPacking list

- SKU

- NB019983

- Display mode

- digital explicit

- Measurement range

- 1~100000mPa·s

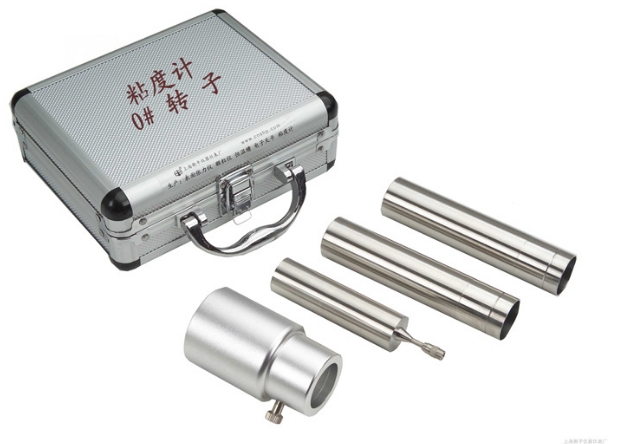

- Rotor specification

- 1 #, 2 #, 3 #, 4 #(0 #optional)

- Rotor speed

- 6/12/30/60rpm

- Measurement Accuracy

- ±2%F.S

- Power supply Voltage

- AC 220V +/- 10% 50Hz +/- 10%

- Interface

- RS-232

- Operating temperature

- 5~35℃

- Dimension

- 380*320*390mm

- Weight

- 4.5kg

- Automatic stop for single measurement

- After the measurement result is stable, the rotor automatically stops

- Allowable Relative Humidity

- ≤80%

Introduction

The NDJ-1 Rotational Viscometer is suitable for measuring the viscosity and rheological properties of various liquids and semi-fluids. It is widely used to determine the viscosity of various fluids such as greases, paints, food, cosmetics, and adhesives. It is one of the most used precision instruments in new product development, product quality control and other testing and analysis.

Features

1. The lifting system adopts helical rack/helical gear mode

The Rotational Viscometers of other domestic (CN) manufacturers are all straight rack/spur gear, and the rack and gear have only one tooth contact when working, and if they want to easily adjust upward, they will slide downward; If self-slipping is avoided, upward adjustment will be difficult. The Rotational Viscometer of our factory adopts the way of helical rack and pinion/helical gear, and the rack and gear are in contact with only three teeth when working, which effectively overcomes the shortcomings of the straight rack/spur gear method, and it is convenient and easy to move up and down, and the positioning is accurate and will not slide (the helical rack/helical gear method is much higher than the straight rack/spur gear method in terms of processing requirements and costs).

2. A universal joint has been added to the interface connecting the rotor

Usually, the rotor of the rotating viscometer is directly rigidly connected with the rotating shaft, and the misalignment of the shaft or the misalignment of the rotor will cause the rotor to shake during the test, affecting the test accuracy. The shaft tip of the rotating shaft is thin and sharp, even inadvertent collision often causes the bending or even damage of the shaft tip, and the universal interface can effectively reduce the test error caused by the misalignment of the shaft and rotor, and protect the shaft tip from impact and damage. This kind of structure has not been seen by other domestic (CN) manufacturers, and has only been seen on imported high-grade viscometers (universal joints need to be processed by imported CNC machine tools, and the accuracy requirements are very high, so the cost has also increased a lot).

3. The variable speed gear is pressed by high wear-resistant and high-performance engineering plastics

In order to make the Rotational Viscometer run smoothly and measure accurately, the machining accuracy of the gear is very high. At present, the gears used in the Rotational Viscometer produced by other domestic (CN) manufacturers are processed into toothed pieces with metal sheets and then riveted with other parts, due to the limitations of this processing method, it is difficult to meet the design requirements, so that the viscometer runs unsmoothly when working, such as shaking, shaking, pointer jumping, etc., and the noise is large. Our factory uses high-performance engineering plastics (its performance is better than metal) to press the entire part of the gear at one time, because of the high precision of the mold, so as to ensure that the processed gear fully meets the design requirements, fundamentally solves the problem caused by metal gears, makes the viscometer very stable when working, and improves the test accuracy.

4. Fine processing and excellent performance

Each part is carefully processed, carefully debugged, and it looks like a precision instrument when you get it, which is in stark contrast to some manufacturers who only know shoddy, low price and low quality.

5. A special thermostat for Rotational Viscometer is provided

The viscosity of a sample tends to vary with temperature, and accurate measurement requires a controlled temperature of the sample. On the basis of long-term production of various types of high-precision thermostats, our factory has designed and produced a variety of high-low temperature thermostats for use with Rotational Viscometers.

Product Display

NDJ-1 Analog Rotational Viscometer

Compatible models:

DCX-130B Miniature Semiconductor Electronic Refrigeration Circulator

DL-SERIES small cryogenic cooler

DC-0506W Viscometer Cryostat Bath

CH1006 High Temperature Bath

- 1Working principle and application scenario analysis of NDJ digital Rotational Viscometer

- 2The importance of viscosity measurement in food production and processing

- 3How to choose and use a viscometer?

- 4On the principle of Rotational Viscometer

Art Gatenby

- 5The Importance of Viscosity Testing in Chocolate and Cakes

- 6Dynamic Viscosity vs Kinematic Viscosity: What's the Difference?

- 7The basic knowledge of viscometer is enough to read this article

- 8Main application fields of Rotational Viscometer

- 9Basic concepts, principles and measurement methods of viscosity

- 10Working Principle and Viscosity Calculation Formula of Rotational Viscometer

- 1NF EN ISO 1157-1999《Plastics - Cellulose acetate in dilute solution - Determination of viscosity number and viscosity ratio.》

- 2 1219-2010《Method for Determination of Viscosity of Hydroxypropyl Methyl Cellulose》

- 3GB/T 14797.2-2008《Natural rubber latex concentrate - Prevulcanized rubber latex - Determination of viscosity》

- 4GB/T 12004.4-2003《Polyvinyl chloride paste--Determination of apparent viscosity by the Brookfield test method》

- 5GB/T 18856.4-2002《Test methods for coal-water slurry mass, part 4, method for determining apparent viscosity of coal-water slurry》

- 6GB/T 15357-2014《Surface active agents and detergents―Determination of viscosity and flow properties of liquid products using a rotational viscometer》

- 7GB/T 265-1988《Petroleum products--Determination of kinematic viscosity and calculation of dynamic viscosity》

- 8JB/T 9357-1999《General technical conditions for laboratory rotational viscometers》

NDJ-1

NDJ-1