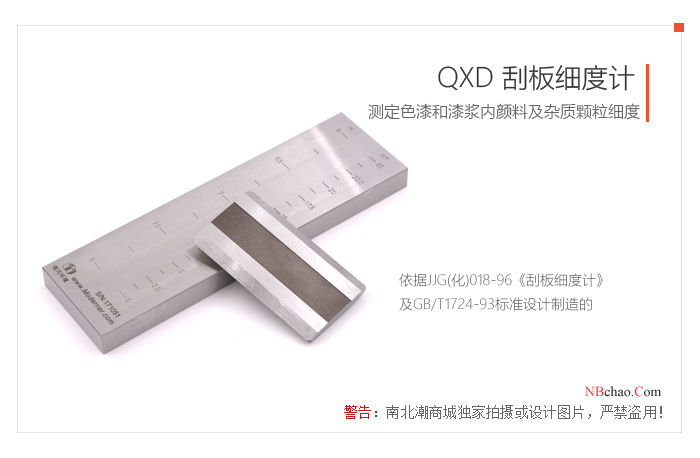

MODERNER QXD-250 single-channe Grindometer 0~250μm

Moderner QXD-250 (single-channe) Single-Channe Fineness of Grind GaugeSPEC

Moderner QXD-250 (single-channe) Single-Channe Fineness of Grind GaugeDetails

Moderner QXD-250 (single-channe) Single-Channe Fineness of Grind GaugePacking list

- SKU

- NB020353

- Scraper type

- Single-channe

- Number of grooves

- 1

- range

- 0~250μm

- Scale unit

- μm

- Scraper size

- 170*50*12mm

- Drawdown blade size

- 70mm

- Graduation

- 10μm

- Groove size

- 12.7mm

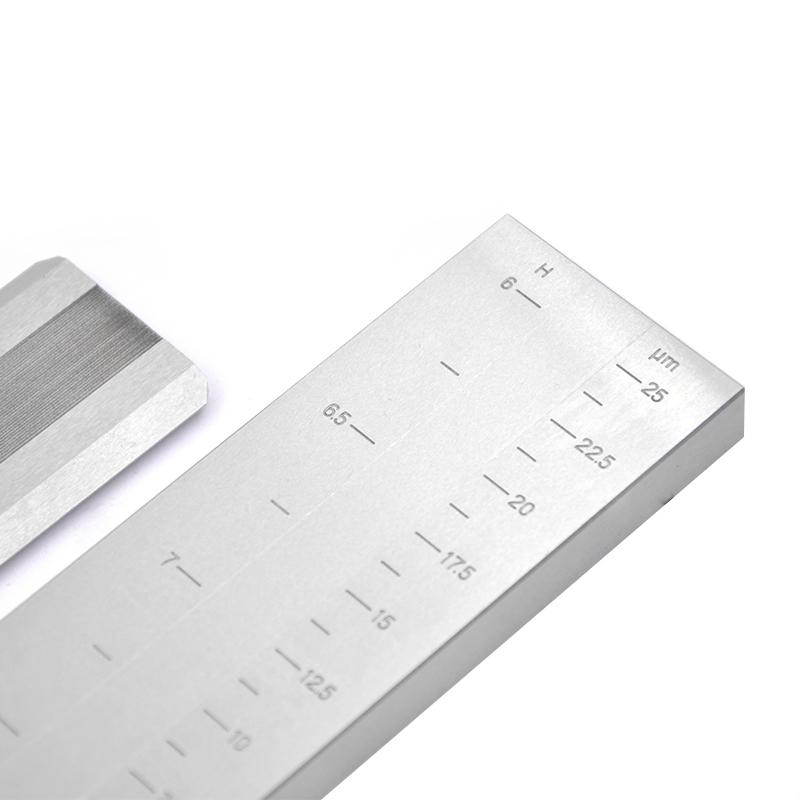

QXD-250 single-slot scraper Fineness Meter is a small stainless steel single-slot scraper Fineness Meter for MODERNER. The measuring range of QXD-250 is 0~250 μm, the graduation value is 10 μm, and the number of grooves is 1. The QXD-25 single-slot scraper Fineness Meter is suitable for particle fineness testing in coatings, pigments, printing inks and other industries. It is a manual fineness testing.

Application

The application areas of QXD single-slot scraper Fineness Meter include paint, plastics, pigments, printing inks, paper, ceramics, food, etc.

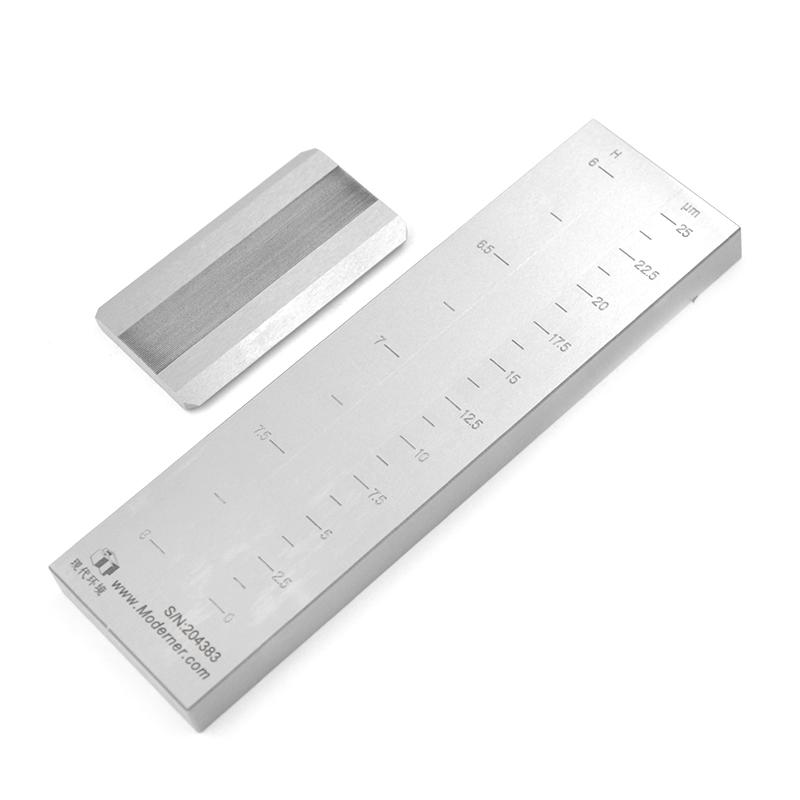

QXD-250 single groove scraper Fineness Meter real shot

How to operate

1. Before using the QXD-250 single-slot scraper Fineness Meter, soak the plate and bottom with a suitable solvent and wipe them dry with cotton yarn.

2. Stir the sample that meets the product's standard viscosity index thoroughly with an ink adjusting knife.

3. Drop a few drops of sample liquid into the deepest part of the groove of the QXD single-slot scraper Fineness Meter .

4. Hold the scraper with the thumb, index and middle fingers of both hands, place it horizontally on the upper end of the stainless steel Grindometer, make the scraper perpendicular to the surface of the Grindometer, and pull the scraper from the deep part to the shallow part of the groove at an appropriate speed. The paint sample fills the grooves without leaving excess paint on the slab.

5. After scraping, immediately (within no more than 5 seconds) hold the QXD single-slot scraper Fineness Meter horizontally and tilt it so that the line of sight is 15-20 degrees from the groove plane, and observe the uniformity of the particles in the groove under the light. and the exposed scale value, the reading value is the fineness of the measured object.

Maintenance

(1) Clean the Fineness Meter immediately after use and apply Vaseline to prevent the Fineness Meter from rusting.

(2) Do not scratch the surface of the QXD-250 single-slot scraper Fineness Meter and the scraper.

(3) When measuring the fineness, the clear oil that meets the product standards should be adjusted first, and then measured with the QXD single-slot scraper Fineness Meter .

(4) Regularly (one year) check the flatness of the knife edge and fineness gauge. If unevenness or fineness gauge wear is found, it needs to be calibrated by the national metrology and verification agency before use.

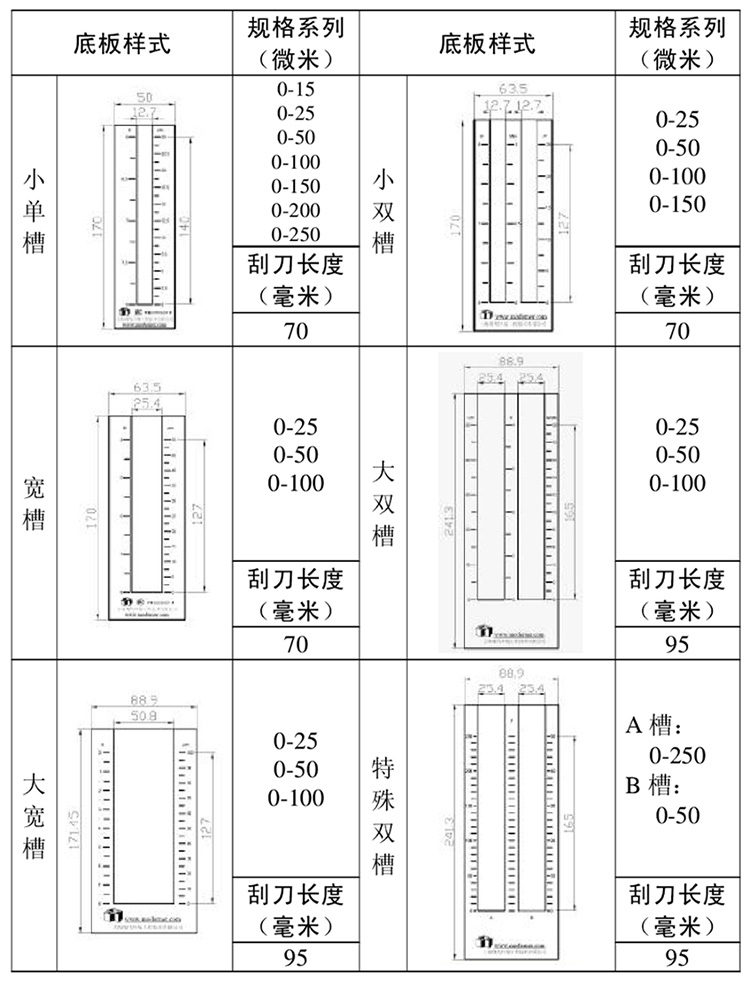

Specification list

Series selection

| Specification | Measuring range | Graduation value | Groove size | unit |

| Small single slot | 0-15 | 0.75 | 12.7*140 | μm |

| 0-25 | 1.25 | Hegman/μm | ||

| 0-50 | 2.5 | |||

| 0-100 | 5 | |||

| 0-150 | 5 | μm | ||

| Small double slot | 0-25 | 2.5 | Hegman/μm | |

| 0-50 | 2.5 | |||

| 0-100 | 5 | |||

| 0-150 | 5 | μm | ||

| wide slot | 0-25 | 1.25 | 25.4*127 | Hegman/μm |

| 0-50 | 2.5 | |||

| 0-100 | 5 | |||

| wide slot | 0-25 | 2.5 | 50.8*127 | |

| 0-50 | 5 | |||

| 0-100 | 5 | |||

| Large double slot | 0-25 | 2.5 | 25.4*165 | Hegman/μm/NPIRI |

| 0-50 | 5 | |||

| 0-100 | 5 | |||

| Special double slot | 0-50 | 2 | μm | |

| 0-250 | 10 | μm |

- 1HG/T 5175-2017《Water-based decorative coating for glass and ceramic products》

- 2ASTM D1210-05-2022《Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage》

- 3JB/T 9385-2017《Scraper fineness gauges》

- 4ASTM D1316-2020《Standard Test Method for Fineness of Grind of Printing Inks By the NPIRI Grindometer》

- 5JJG 905-2010《Fineness of Grind Gage》

- 6ASTM D333-2021《Standard Guide for Clear and Pigmented Lacquers》

- 7ISO 1524-2020《Paints, Varnishes And Printing Inks - Determination Of Fineness Of Grind》

- 8GB/T 13217.3-2008《Test method for fineness of grind of liquid ink》

- 9QB/T 2025-1994《Lithographic inks》

- 10ASTM D1210-1996《Standard Test Method for Determination of Dispersion Fineness of Pigment-Paint Systems》

QXD-250 (single-channe)

QXD-250 (single-channe)