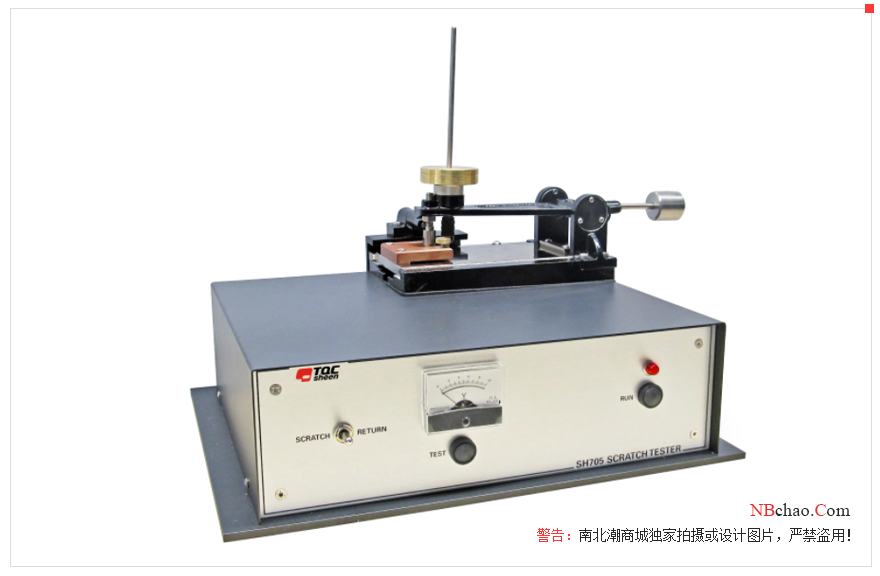

TQC Sheen SH0530 coating surface scratch resistance instrument

SETQC Sheen SH0530 coating surface scratch resistance instrument is a mechanical Scratching Tester for evaluating coating Hardness, SH0530 scratch resistance instrument can test Coating thickness up to 0.3mm, panel size is 100x150x1.6mm.

$9911.00/set

PromotionLoading...

Coupon

Model:

TQC sheen SH0530 Coating surface scratch resistance instrumentSPEC

TQC sheen SH0530 Coating surface scratch resistance instrumentDetails

TQC sheen SH0530 Coating surface scratch resistance instrumentPacking list

- SKU

- NB020785

- Scribe traverse speed

- 35mm/s

- Maximum size of test sample

- 100*150*1.6mm

- Maximum thickness of test sample

- 0.3mm

- meet the standard

- ISO 1518-1

- Load (loading) range

- 20N

- Power supply Voltage

- 230VAC 50HZ

SH0530

Coating surface scratch resistance instrument

Introduction

The mechanized scratch Tester is used for coating hardness evaluation based on the scratch resistance method.

Clamp the test plate tightly and move it slowly while scraping the surface with a stylus or alternative tool. Depending on the test procedure, specified or variable loads can be applied to obtain varying degrees of failure, from traces to destruction. The voltmeter indicates the contact between the tool and the metal sample substrate. Maximum panel size: 100x150x1.6mm (0.3mm coating).

The TQC Sheen SH0530 Scratch Resistance Tester for Coated Surfaces meets the weight settings required by the ISO 1518-1 standard. Weight groups specified in the previous international standard ISO 1518 can be selected.

Product display

FAQ

QSH705 I want this one.

A

SH705 is the current SH0530.

The 705 is the old model before SHEEN. After it was acquired by TQC, it was called SH0530, and the machine has not changed.

QMay I ask your data, is it based on that pointer beating? To record the data, or to see if the film on the surface is broken.

A

This is the metal bottom, and once its membrane is scratched, the current of the Scratch meter passes through the current pointer, which means that the pointer is scratched, the coating is scratched, and the ammeter in the middle of the machine will swing. The test is to gradually apply weight. Generally, the test is about 10 cycles, and the average value of sexual repeability is also taken.

QCan we normally use 220V voltage?

A

The information says 230V, and it can work normally at the domestic voltage of 220V, don't worry.

QCan all coating surface scratch resistance instruments be used for inspection in GB/T15102 standard?

A

Not necessarily, but this SH0530 coating surface scratch resistance instrument can be considered.

Standard

- 1ISO 1518《Paints and varnishes — Determination of scratch resistance — Part 1: Constant-loading method》

- 2ISO FDIS 1518-2010《Paints and varnishes. Scratch test》

- 3 1518-2010《Paints and varnishes. Scratch test》

- 4GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 5ISO 1518-1-2023《Paints And Varnishes - Determination Of Scratch Resistance - Part 1: Constant-Loading Method》

- 6GB/T 22374-2018《Floor coating》

- 7ISO 12137-2011《Paints and varnishes Determination of mar resistance》

- 8SY/T 4113-2007《Pipeline coating test method.Part 1 : Gouge resistance test》

- 9GB/T 17657-2013《Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels》

- 10GB/T 15102-2017《Surface decorated fiberboard and particleboard with paper impregnated thermosetting resins》

SH0530

SH0530