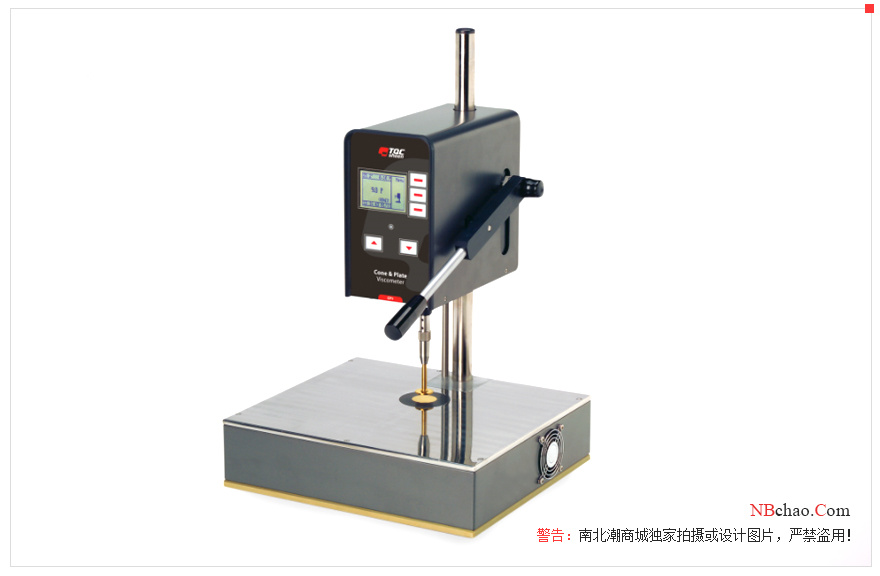

TQC Sheen SH1693 Cone-plate Viscometer (CP1)

TQC sheen SH1693 Con-plate viscometerSPEC

TQC sheen SH1693 Con-plate viscometerDetails

TQC sheen SH1693 Con-plate viscometerPacking list

- SKU

- NB020878

- Display mode

- digital explicit

- Viscosity range

- 0~5P, 0~10P, 0~20P, 5~50P, 10~100P

- Power supply Voltage

- 90-240V AC – 50/60 Hz

- peripheral interface

- USB

- Application standard

- BS 3900;A7, ASTM D 4287, ISO 2884

- Dimensions

- 350*300 555mm

- Instrument Weight

- 15kg

- Temperature range

- 5~65℃

Introduction

The Cone Plate Viscometer (CP1) is the standard test for dynamic viscosity measurement. It is faster and more accurate by using a new high-precision microprocessor control. Since non-Newtonian fluids exhibit different viscosities relative to the applied shear rate, the cone plate viscometer strictly controls them to 10,000S-1 (B.S./ISO requirements) or 12,000S-1 (ASTM). These are often thought of as representing paint applications through rollers or brushes, and therefore reflect "real world" applications.

Temperature control

Since most viscosity measurements are temperature sensitive, the sample is placed on a temperature control plate that can be set between 5°C and 65°C.

There is no cone kit for the conical and base units. The cone kit is ordered separately.

Features

• Interchangeable cones for easy installation with quick-release chucks for easy cleaning

• Available in four units: P, cP, Pa.s or mPa.s

• Pre-selected or adjustable run time 5-59 seconds, manual or auto-start

• Fast temperature control, warm-up time adjustable 0-59 seconds

• Adjustable limit/tolerance settings with warnings

• User calibration: viscosity (for any cone of certified oils) and temperature

• Memory for 100 readings, 3-digit adjustable sample identification, RS232 PC/printer data output

• Simple menu-guided/soft-key operation: cone range, parameter setting, readings, set point and plate temperature, speed, viscosity, sample identification, calibration, date

• Selectable modes: full-featured or simplified routines, security protection.

Meets standards

ASTM D4287, ISO 2884, BS 3900-A7.

Product display

- 1GB/T 13217.4-2020《Test method for viscosity of ink》

- 2SH/T 0751-2005《Standard test method for measuring viscosity at high temperature and high shear rate by tapered-plug viscometer》

- 3GB/T 9751-1988《Determination of viscosity of coatings at a high rate of shear》

- 4GB/T 9751.1-2008《Paints and varnishes -Determination of viscosity using rotary viscometers - Part1 : Cone and-plate viscometer operated at a high rate of shear》

- 5ASTM D4287-2000《Determination of high shear viscosity by cone-plate viscometer》

- 6ISO 2884-1-1999《Paints and varnishes - Determination of viscosity with rotational viscometers - Part 1: cone-plate viscometers operating at high shear rates》

SH1693

SH1693