Kenton 101-2AS digital display electric Forced Air Drying Oven, stainless steel inner tank 300 ℃/136L

SE-

Kenton 101-2 Dial-Type electric Forced Air Drying Oven, galvanized tank inner tank 300 ℃/136L$ 311.00SE

Kenton 101-2 Dial-Type electric Forced Air Drying Oven, galvanized tank inner tank 300 ℃/136L$ 311.00SE -

Kenton 101-2A digital display electric Forced Air Drying Oven, galvanized bile 101 oven 300 ℃/136L$ 333.00SE

Kenton 101-2A digital display electric Forced Air Drying Oven, galvanized bile 101 oven 300 ℃/136L$ 333.00SE -

RONGHUA DHG-9101-2A Electric thermostatic blast Drying Oven$ 541.00SE

RONGHUA DHG-9101-2A Electric thermostatic blast Drying Oven$ 541.00SE -

Kenton 101-2S Dial-Type electric Forced Air Drying Oven, stainless steel 101 oven 300 ℃/136L$ 494.00SE

Kenton 101-2S Dial-Type electric Forced Air Drying Oven, stainless steel 101 oven 300 ℃/136L$ 494.00SE -

Ronghua DHG-9101-2 Electrothermal Constant Temperature Forced Convection Oven$ 438.00SE

Ronghua DHG-9101-2 Electrothermal Constant Temperature Forced Convection Oven$ 438.00SE

Kenton 101-2AS Digital display electric Forced Air Drying OvenSPEC

Kenton 101-2AS Digital display electric Forced Air Drying OvenDetails

Kenton 101-2AS Digital display electric Forced Air Drying OvenPacking list

- SKU

- NB021105

- Temperature range

- RT+5~300°C

- Temperature fluctuation

- ±1%

- Accuracy

- ±1℃

- Interior size

- 550*550*450mm

- Inner chamber material

- stainless steel

- Enclosure Material

- Metallic paint spraying

- thermostat

- Microcomputer intelligent PID digital display

- Viewing Window

- Yes.

- Power

- 220V

- Input power

- 1.6 ~ 2.4Kw

- Dimensions

- 790*870*640mm

Recommendations

It is suitable for routine testing in industrial and mining enterprises, basic laboratories and workshops. It is not recommended for long-term uninterrupted use. It is not recommended for samples with high temperature uniformity requirements and large moisture content. For more expensive samples, it is recommended to install an independent temperature limit controller.

Application

It is used for drying, baking, heat treatment, and heating by industrial and mining enterprises, laboratory scientific research units, etc., but it is not suitable for volatile, flammable, explosive and other items to avoid causing explosions.

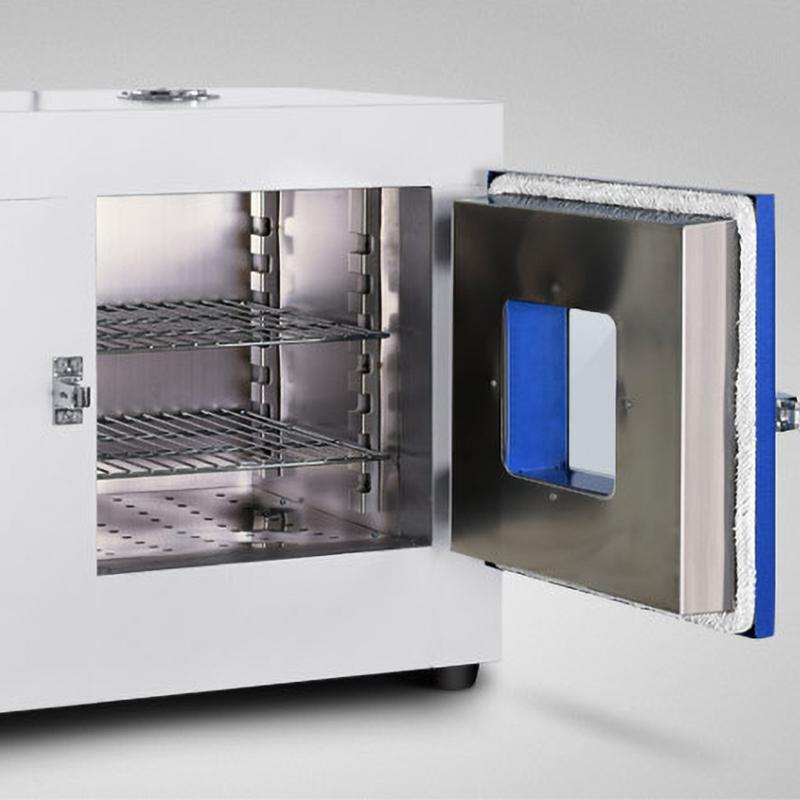

Structural features

1. The thermostat is divided into two types: Dial-Type and microcomputer intelligent PID digital display;

2. The outer casing is spray-painted with metallic paint, and the overall design is beautiful and elegant;

3. The hot air circulation system consists of low-noise fans and air ducts;

4. The inner tank is divided into two types: mirror stainless steel and galvanized steel plate;

5. The height and number of shelves in the studio can be adjusted to facilitate access to samples of different specifications;

6. The box door is equipped with a double-layer tempered glass observation window, which can clearly observe the contents of the box.

Optional :

1. Intelligent digital display temperature controller with timing function;

2. Independent temperature limit controller.

product specifications

model | Studio specificationsmm (Height à Width à Depth) | Voltage | power | Temperature control range | Accuracy | Volatility |

Pointer type electric blast Drying Oven (galvanized inner tank) | ||||||

101-0 | 350Ã350à 350mm | 220V | 0.8~1.6Kw | RT+5~300 ℃ | ±1 ℃ | ±1 % |

101-1 | 450Ã450Ã 350mm | 0.8~ 1.6Kw | ||||

101-2 | 550Ã550Ã 450mm | 1.6~2.4 Kw | ||||

101-3 | 750Ã600à 500mm | 2~ 3Kw | ±2 % | |||

101-4 | 1000Ã800Ã 800mm | 380V | 3~ 4.8Kw | |||

101-5 | 1000Ã1000Ã 1000mm | 4~6 | ||||

Digital display electric Forced Air Drying Oven (galvanized liner) | ||||||

101-0A | 350Ã350à 350mm | 220V | 0.8~ 1.6Kw | RT+5~300 ℃ | ±1 ℃ | ±1 % |

101-1A | 450Ã450Ã 350mm | 0.8~ 1.6Kw | ||||

101-2A | 550Ã550Ã 450mm | 1.6~2.4 Kw | ||||

101-3A | 750Ã600à 500mm | 2~ 3Kw | ±2 % | |||

101-4A | 1000Ã800Ã 800mm | 380V | 3~ 4.8Kw | |||

101-5A | 1000Ã1000Ã 1000mm | 4~ 6Kw | ||||

Pointer type electric Forced Air Drying Oven (stainless steel liner) | ||||||

101-0S | 350Ã350à 350mm | 220V | 0.8~ 1.6Kw | RT+5~300 ℃ | ±1 ℃ | ±1 % |

101-1S | 450Ã450Ã 350mm | 0.8~ 1.6Kw | ||||

101-2S | 550Ã550Ã 450mm | 1.6~2.4 Kw | ||||

101-3S | 750Ã600Ã 500mm | 2~ 3Kw | ||||

101-4S | 1000Ã800à 800mm | 380V | 3~ 4.8Kw | ±2 % | ||

101-5S | 1000Ã1000Ã 1000mm | 4~ 6Kw | ||||

Digital display electric Forced Air Drying Oven (stainless steel liner) | ||||||

101-0AS | 350Ã350à 350mm | 220V | 0.8~ 1.6Kw | RT+5~300 ℃ | ±1 ℃ | ±1 % |

101-1AS | 450Ã450Ã 350mm | 0.8~ 1.6Kw | ||||

101-2AS | 550Ã550Ã 450mm | 1.6~2.4 Kw | ||||

101-3AS | 750Ã600à 500mm | 2~ 3Kw | ±2 % | |||

101-4AS | 1000Ã800Ã 800mm | 380V | 3~ 4.8Kw | |||

101-5AS | 1000Ã1000Ã 1000mm | 4~ 6Kw | ||||

- 1SL 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 2GB/T 9995-1997《Determination of moisture content and moisture regain of textile--Oven-drying method》

- 3GB/T 6102.1-2006《Test method for moisture regain in raw cotton by oven drying》

- 4GB/T 6978-2007《Test method for the determination of scoured yield of greasy wool - Drying oven method》

- 5GB/T 10514-2012《Determination of free water for nitrophosphate - Oven method》

- 6GB/T 24131.1-2018《Rubber, raw—Determination of volatile matter content—Part 1:Hot-mill method and oven method》

- 7GB/T 30648.5-2015《Paints and varnishes—Determination of resistance to liquids—Part 5: Temperature-gradient oven methods》

- 8SL/T 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 9GB/T 32710.10-2016《Safety requirements for environmental testing and conditioning equipment—Part 10: Electric gravity convection ovens and forced ventilation ovens》

- 10GB/T 30435-2013《Electric gravity convection and forced ventilation ovens》

101-2AS

101-2AS