HENGLI KZ-50 LCD Vacuum Oven pointer display, manual control

SE-

Kenton DZF-6050S constant temperature vacuum Drying Oven, stainless steel liner$ 840.00SE

Kenton DZF-6050S constant temperature vacuum Drying Oven, stainless steel liner$ 840.00SE -

HENGLI KZ-50G LCD Vacuum Oven digital display electronic automatic control$ 1858.00SE

HENGLI KZ-50G LCD Vacuum Oven digital display electronic automatic control$ 1858.00SE -

RONGHUA DZF-6050 Vacuum Oven 50~250 ℃$ 718.00SE

RONGHUA DZF-6050 Vacuum Oven 50~250 ℃$ 718.00SE -

HUITAI DZF-6050 Vacuum oven 2 stencil plates can be extracted, volume 50L$ 665.00SE

HUITAI DZF-6050 Vacuum oven 2 stencil plates can be extracted, volume 50L$ 665.00SE -

Kenton DZF-6050 constant temperature vacuum Drying Oven, cold-rolled plate liner$ 677.00SE

Kenton DZF-6050 constant temperature vacuum Drying Oven, cold-rolled plate liner$ 677.00SE

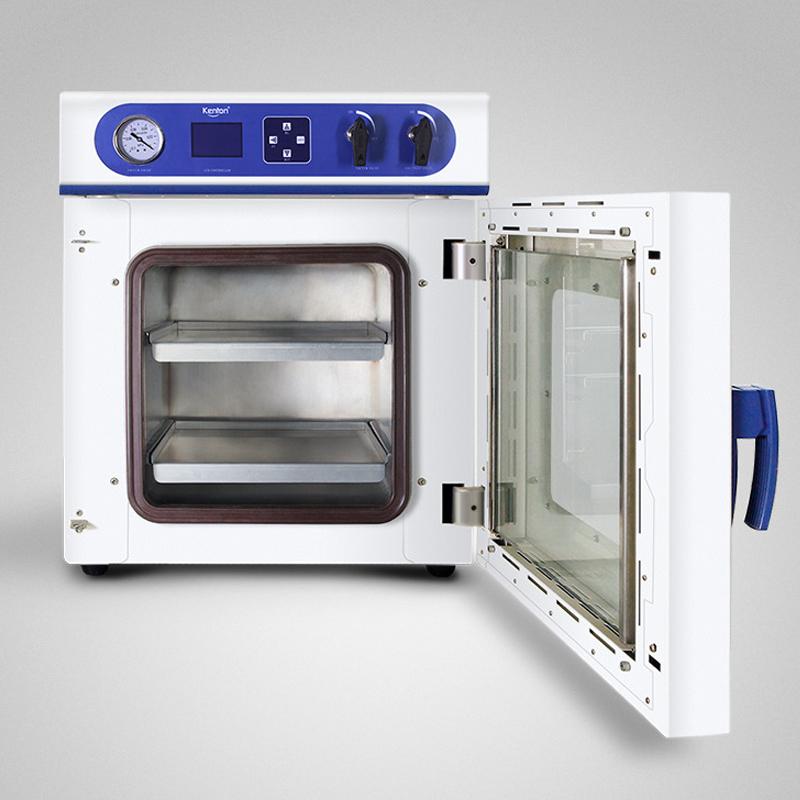

HengLi KZ-50 Vacuum OvenSPEC

HengLi KZ-50 Vacuum OvenDetails

HengLi KZ-50 Vacuum OvenPacking list

- SKU

- NB021252

- Temperature range

- RT+50~250℃

- Temperature Fluctuation

- ±0.5

- Temperature Resolution

- ±0.1

- Volume

- 50L

- Interior size

- 375*348*385mm

- Chamber material

- SUS304 stainless steel

- Shelf (std.)

- 2pcs

- Timer

- 0~99 hours, 0~9999min, optional

- Vacuum Meter

- Pointer display manual control

- Power

- Single phase AC220V/50Hz

- Input Power

- 1200W

- Ambient Temperature

- 10~30℃

- Relative Humidity

- Relative Humidity below 70%

- Dimensions

- 635*550*783mm

product description

•Specially designed for drying heat-sensitive and easily oxidized substances, especially suitable for powdery or granular samples, and effectively shortens the drying time, so it is used in biopharmaceutical, medical, agricultural research and other fields;

•Adopt ALLHEAT™ cavity pre-heating technology and SH-Transfer™ shelf heat transfer and other professional patented technologies to make the temperature distribution in the cavity uniform, and the constant temperature ensures the smooth progress of the experiment;

• Can provide Chinese/English IQ, OQ, PQ. And can provide a variety of verification services;

• This series of products has passed the EU CE safety certification, complies with the Australian AS/NZS3350 standard, and enjoys a 2-year quality warranty period.

Cavity Preheating Technology

ALLHEATTM professional cavity preheating technology is to distribute heating elements evenly around the inner tank to preheat the inner wall of the inner cavity, and then through heat transfer and forced fan convection, the temperature of each point in the cavity can be accurately reached and Keep at the set value to ensure uniform temperature distribution in the chamber;

Equipped with ALLHEATTM series products, due to the uniform distribution of heat, it has the characteristics of low energy consumption and difficult heat loss, which reduces the cost of use for customers.

ALLFLOWTM good air circulation system

Good forced convection ALLFLOWTM air circulation system ensures the shortest temperature recovery after opening the door. Cooperate with the international famous brand with cooling fan (maintenance-free, high durability), so that the experiment and training effect can reach a satisfactory level.

The ALLFLOWTM air circulation system fully guarantees the continuous stability of the temperature in the working chamber, the wind speed can be adjusted, and it has a fan switch function. When the temperature set by the customer is reached, the sample is given a good environment for baking/cultivation.

ALLSENSTM microcomputer PID control technology

Integrated LCD dot-matrix large-screen LCD display, which can be displayed in Chinese or English, and all parameters can be displayed at a glance.

Humanized design, fully display the status display required by customers: temperature, wind speed, running time, running stop.

Adaptive PID level control, precise temperature control, prevent temperature overshoot, and keep the temperature in the cavity uniform and constant.

User password control, built-in multi-function memory menu, and can be connected to multiple (up to 16) devices at the same time through the standard RS485 interface for real-time monitoring.

To meet customer selection needs, wide time setting: 0~99 hours, 0~9999 minutes.

All setting operations have confirmation sound prompts, which is easy to operate.

Computer software can be used for remote control, professional supporting operation ALLSENSTM programmable software (optional).

Pro-InsulationTM insulation technology

Based on the concept of effective utilization of heat energy, a complete isolation design is adopted between the entire inner tank and the outer shell to avoid energy loss caused by heat transfer.

Imported high-density thermal insulation material is used to wrap the inner tank, which can effectively insulate and keep heat.

Excellent silicone door seal, isolated door hinge design, and door handle with fastening device to ensure airtightness.

Sophisticated imported temperature sensing parts

The original imported industrial grade PT100 temperature sensor has a fast response time when there is a step change in temperature, and the influence of self-heating temperature is small.

Ergonomic structure design

Modern laboratory classic product color matching, international popular design, arc-shaped design concept adds highlights to the laboratory and increases operating comfort;

The unique integrated design of the outer door and LCD control panel conforms to the ergonomic structure, comfortable Viewing Angle, and the opening of the outer door and the interface operation are convenient and simple;

Movable mesh partitions, the interval and quantity can be adjusted according to customer needs, and the maximum capacity can meet various experiments and culture items;

Humanized vertical classic structure design, maximizing the use of the working cavity;

The double door design (equipped in the Incubator series) allows real-time control of the sample status in the inner cavity, and at the same time makes the insulation performance better.

Clean and convenient

• The concept of the arc-shaped inner tank around is easy to clean, and the minimal splicing design is convenient for cleaning and maintenance;

• Removable removable multi-layer partition design, less metal fittings in the cavity and easy to clean.

easy maintenance

•The liquid crystal microelectronic controller has a diagnostic function, and actually displays various working states and stores historical operation and temperature data;

• The inner cavity is made of SUS304 stainless steel, which has good anti-corrosion performance and high durability;

•The main control and control panel of electrical control components are installed on the upper part of the box, which is convenient for maintenance and maintenance of the equipment.

Safe and effective protection concept

• Multi-parameter abnormal alarm function, and has sound and light prompts;

• Automatic double over-temperature safety protection function;

• All electronic components are certified by UL;

• All over-temperature protection devices are designed in accordance with the German DIN 12880 CLass3.1 standard;

• The observation window is double protected by explosion-proof and tempered glass, which effectively improves the safety of operators;

•Special shatter-proof safety glass panel with flexible suspension and anti-pressure protection device in the door frame, which avoids damage to operators caused by fragments due to pressure or rupture.

• All technical data are tested under no-load conditions, ambient temperature 25°C, Relative Humidity 50%RH, Voltage fluctuation ±10%, and fully comply with DIN12880 standard requirements.

In line with international standards

• Temperature safety standard: German DIN 12880 Class3.1.

• Electrical safety standards: International IEC 61010-1; American UL 61010-1; European Union EN 61010-1.

- 1The working principle and application of vacuum Drying Oven

- 2What should be paid attention to in the use of industrial vacuum ovens?

- 3Hengli full series of box equipment selection table

- 4What factors affect the drying effect of the Drying Oven and how to solve it?

- 5 Common user questions about constant blast and vacuum Drying Oven (the problem of choosing a vacuum Drying Oven)

- 1JB/T 11365-2013《Vacuum dryer》

- 2SJ 21318-2018《General specification for vacuum high-temperature ovens》

- 3GB/T 8077-2023《Methods for testing uniformity of concrete admixtures》

- 4GB/T 6500-2008《Test method for moisture regain of hair fibers - Oven method》

- 5GB/T 8576-2010《Determination of free water for compound fertilizers - Vacuum oven method》

- 6GB/T 29251-2012《Vacuum ovens》

- 7HG/T 5180-2017《Water-based Coatings for Automotive Plastic Parts》

- 8HG/T 5164-2017《Textile dyeing and finishing auxiliaries - Water-borne polyurethane emulsions for textile coating》

- 9GB/T 462-2008《Paper、board and pulp - Determination of moisture content of analytical sample》

- 10GB/T 5211.3-1985《Determination of volatile matter of pigments at 105℃》

KZ-50

KZ-50