Shanghai PUSHEN A20-339 Rubber alcohol Wear resistance Tester 0~50mm

Pushen A20-339 Rubber alcohol Wear resistance TesterSPEC

Pushen A20-339 Rubber alcohol Wear resistance TesterDetails

Pushen A20-339 Rubber alcohol Wear resistance TesterPacking list

- SKU

- NB022087

- Friction method

- linear

- Frictional contact form

- point

- Friction medium

- alcohol

- Number of grinding heads

- 2

- friction load

- 10g、20g、25g、50g、100g、200g、500g

- Rotation speed

- 1-80 times/min (round trip) adjustable

- Test Travel

- 0-50Mm adjustable

- Count range

- Count 0-999999 times

- Power supply Voltage

- AC220V 50/60Hz

- Machine size

- 575*450*280mm

- Total Power

- 50W

Introduction

This machine is designed and manufactured in accordance with ASTM1966* 2058 Friction Verification Regulations# in Taiwan, CHINA. It is composed of good stainless steel shell, aluminum alloy fixture and precision parts, with precise structure, exquisite and beautiful shape, and its technical content is in a professional position among similar products.

The machine is suitable for all kinds of surface spraying products and printing font friction resistance life test. It has adjustable speed and visual display of speed during testing, and the number of tests can be set at the same time. The test results are accurate and the operation is simple and easy.

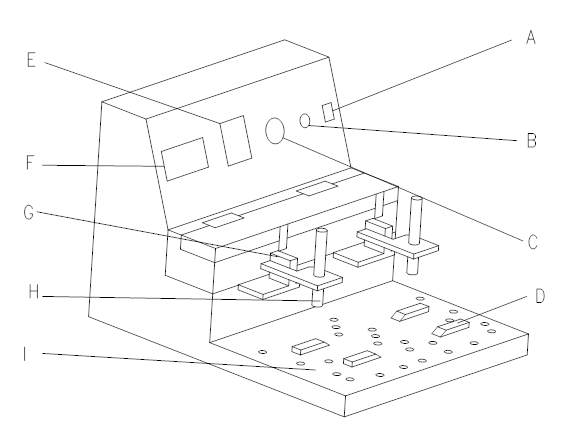

Structural diagram of the machine

A. Power switch;B. tachometer;C. a working switch;D. a fixture;E, governor;F. a counter;G. a height adjustment handle;H. Friction head fixture;I. Working platform

A20-339

A20-339