Shanghai HUXI JRJ300-D-1 Shear emulsification Stirrer

SEHuXi JRJ300-D-1 Stirrer of shear emulsificationSPEC

HuXi JRJ300-D-1 Stirrer of shear emulsificationDetails

HuXi JRJ300-D-1 Stirrer of shear emulsificationPacking list

- SKU

- NB023083

- Speed range

- 200~11000rpm

- Capacity

- 40L

- Input power

- 510W

- output power

- 300W

- Dimensions

- 250*650*720mm

- Power

- AC 220 V 50 Hz

- Max Torque

- 34.1N.cm

- Impeller configuration

- F70mm

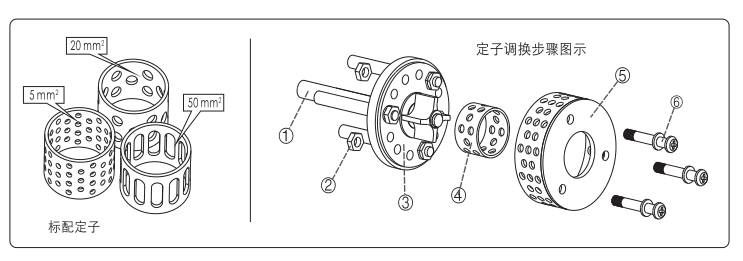

- stator configuration

- 5mm²,20mm²,50mm²

The laboratory high-speed shear and dispersion emulsifier is driven by a compact series type micro high-speed motor, which is suitable for the stirring and mixing of low-to-medium and high-viscosity liquids in the laboratory or pilot plant, and the shearing and emulsification of granular materials in liquid media. The machine is composed of a high-density die-cast aluminum alloy drive motor for the body, a shear emulsification head made of good stainless steel and a speed controller.

Basic construction

This machine is composed of a running state controller, a drive motor and a shearing and emulsifying mixing head.

● The running state controller adopts stepless governor, and the digital display type adopts touch junctionstructure, speed regulation is convenient, and the data is correct.

● The drive motor adopts a series excited micro motor with large output power and compact structureSafe and reliable.

● The shear emulsifying stirring head is made of good stainless steel, with good corrosion resistance.The interchangeable stator is easy to disassemble and assemble.

● The shearing emulsification stirring head is connected with the drive motor by connecting shaft joints, which is high-speedstable operation.

Serial models

| Product model | JRJ300-D-1 | JRJ300-SH (Digital Display) |

| Input power | 510W | 510W |

| Output power | 300W | 300W |

| Speed range | 200-11000R/min | 200-11000R/min |

| Dimensions | 250x320x720mm | 250x320x720mm |

| Throughput | 40L | 40L |

| Head diameter | φ70mm | φ70mm |

| Stator configuration | 5mm2 20mm2 50mm2 | 5mm2 20mm2 50mm2 |

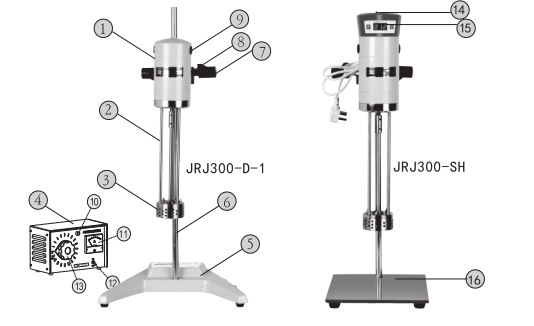

Structure

1.Emulsifying host 2.Transmission shaft 3.Working head 4.Speed control box 5.Machine base 6.Column 7.Support fixed bracket 8.Strut 9.Brush 10.Indicator light 11.Ammeter 12.Power switch 13.Speed control turntable 14.Switch 15.Digital display 16. Flat base

Shear emulsification principle

The experimental equipment is driven by a high-speed motor to shear the emulsification head. Under the high-speed rotation of the rotor, the precise working head turns the stator, forming a high-frequency, strong comprehensive kinetic energy such as circumferential tangential velocity and angular velocity, which promotes the experimental material to be sucked into the rotor area from the bottom of the experimental vessel and thrown out of the stator hole under the action of huge centrifugal force. The stator and rotor form strong, reciprocating comprehensive effects such as hydraulic shear, friction, centrifugal extrusion, and liquid flow collision in a reasonable and narrow gap.

The above working process is repeated in the vessel and subjected to up to tens of thousands of shears, tears, impacts and mixes per minute, so as to achieve the effect of shear emulsification, and its efficiency is about 1,000 times higher than that of ordinary stirring.

Laboratory shear emulsifiers are used for tissue dispersion in the field of biotechnology, sample preparation in the field, enzymatic treatment in the food industry and experiments with liquid and liquid phases, liquid and solid phases in industry, cosmetics industry, paint industry and petrochemical industry. It can make the experimental medium refine under the triple action of extrusion, strong impact and loss of pressure expansion in the material liquid, and mix with each other more evenly, so as to prevent or reduce stratification with the material liquid. Such as: the homogenization and emulsification process in the production process of dairy, beverages, cosmetics, * products and other products. The different specifications of the working head stator configuration are designed to meet different experimental needs. It covers a broader application area - crushing and emulsifying, homogenization, polymerization, suspension, dissolution and stirring, etc.

JRJ300-D-1

JRJ300-D-1