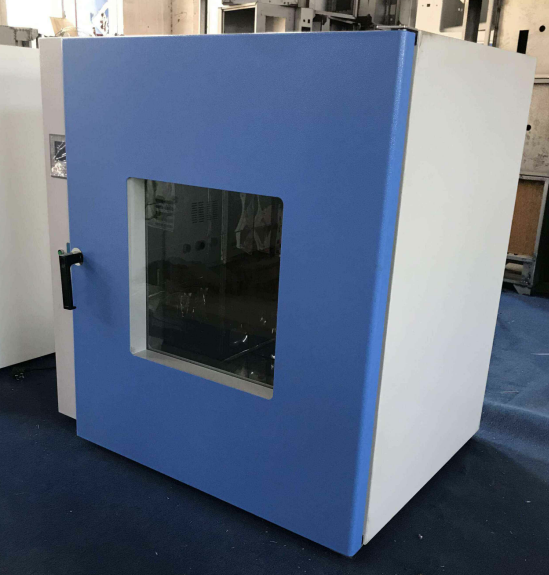

BOZHEN DHG-9030A Forced Air Drying Oven

-

SANFA DHG-9030A Electric thermostatic Drying Oven 30L/stainless steel$ 354.00SE

SANFA DHG-9030A Electric thermostatic Drying Oven 30L/stainless steel$ 354.00SE -

CHINA DHG-9030A vertical Forced Air Drying Oven circulating Electric Oven 200 ℃/30L$ 323.00SE

CHINA DHG-9030A vertical Forced Air Drying Oven circulating Electric Oven 200 ℃/30L$ 323.00SE -

BENTING CBGL-30B vertical standard Forced Air Drying Oven 300 ℃/30L oven

BENTING CBGL-30B vertical standard Forced Air Drying Oven 300 ℃/30L oven -

SANFA DHG-9030 Electric thermostatic Drying Oven 30L$ 321.00SE

SANFA DHG-9030 Electric thermostatic Drying Oven 30L$ 321.00SE -

HUITAI DHG-9030A Blast drying oven temperature control RT + 10~ 250 ℃ Volume 30L$ 363.00SE

HUITAI DHG-9030A Blast drying oven temperature control RT + 10~ 250 ℃ Volume 30L$ 363.00SE

BoZhen DHG-9030A Forced Air Drying OvenSPEC

BoZhen DHG-9030A Forced Air Drying OvenDetails

BoZhen DHG-9030A Forced Air Drying OvenPacking list

- SKU

- NB024280

- Temperature range

- RT+10~250℃

- Temperature Fluctuation

- ±0.5℃

- Temperature Resolution

- 0.1℃

- Interior size

- 340*325*325mm

- Volume

- 35L

- Shelf (std.)

- 2pcs

- Timer

- 1~9999min

- Power supply Voltage

- 220V 50HZ

- Input Power

- 850W

- Environmental temperature

- RT+5~40℃

Introduction

Uses: For industrial and mining enterprises, laboratories, scientific research units, etc. for drying, baking, wax melting, sterilization.

Features

1. The box is made of mirror (brushed) stainless steel argon arc welding, and the box is made of good steel plate, which is beautiful and novel.

2. It adopts a microcomputer temperature controller with temperature control protection and digital display, with timing function, accurate and reliable temperature control, and an intelligent segmented program temperature controller.

3. The hot air circulation system is composed of a fan that can run continuously at high temperature and a suitable air duct. The temperature in the work room is uniform.

4. Independent temperature limit alarm, automatic interruption when the limit temperature is exceeded, to ensure the safe conduct of the experiment without accidents (optional).

5. It has RS485 interface, which can be connected to the Recorder and computer, and can record the changes of temperature and humidity parameters (optional).

Temperature control instrument

The product adopts comprehensive electromagnetic compatibility design and humanized menu design, and adopts the company's self-developed adaptive temperature control technology for temperature control, which makes the equipment operation completely fool-proof, and solves the shortcomings of the previous PID control technology that requires multiple parameter tuning, temperature overshoot, etc., and the temperature control effect is very good. Liquid crystal display, the value indication is clear and intuitive. Microcomputer intelligent control, after setting the temperature, the instrument controls the heating power by itself, and displays the heating status, and the temperature control is accurate and stable. Over-temperature alarm and automatically cut off the heating power. There is a timer function, and the timer time is up to 9999 minutes. It has the function of parameter memory and incoming call recovery for protection due to data loss caused by power failure and crash state.

Insulation

From the inside to the outside, there is an inner cavity, an inner shell, ultra-fine glass fiber, and an air interlayer, and the heat loss of the inner tank is less. The inner tank and door tank mechanism are unique, which greatly reduces the external heat transmission of the inner cavity.

The internal structure of the box

The heat of the electric heater placed on the back of the box is discharged forward through the side air duct, and then sucked in by the high-performance special fan on the back after the dry material, forming a reasonable air duct, which can make the hot air fully convective and make the temperature in the box as uniform as possible.

The external structure of the cabinet

It adopts a novel streamlined arc design, the shell is made of cold-rolled steel plate, and the surface is electrostatically sprayed; the shelving in the studio can be adjusted arbitrarily according to the user's requirements; the inner tank is made of stainless steel, and the semi-circular corner design makes cleaning more convenient;

sensor

Class A PT100 Platinum Resistor; Heating method: Nichrome alloy electric heater

- 1JB/T 5520-1991《Technical conditions for drying oven》

- 2GB/T 16777-2008《Test methods for building waterproofing coatings》

- 3GB/T 1979-1979《Paint film prepative method for determination of resistance to humid heat, salt fog and weather (artificial acceleration)》

- 4GB 1727-1992《Paint film general preparatory method》

DHG-9030A

DHG-9030A