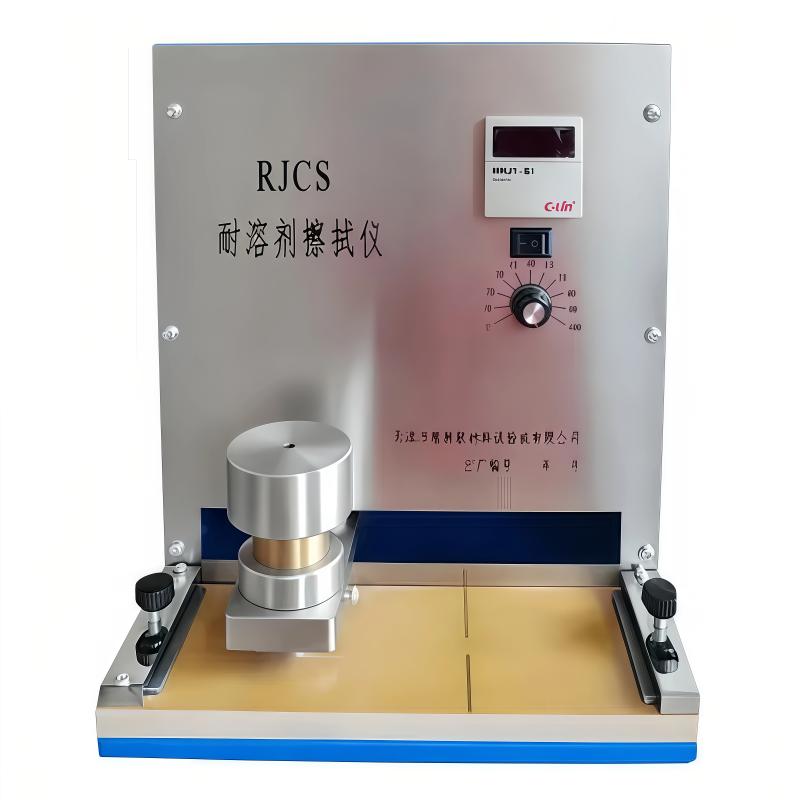

JINGKELIAN RJCS solvent resistance Tester coating solvent wiping resistance

SEJingKeLian RJCS Resistance to solvent TesterSPEC

JingKeLian RJCS Resistance to solvent TesterDetails

JingKeLian RJCS Resistance to solvent TesterPacking list

- SKU

- NB026334

- friction load

- 1000±10g

- Scrub stroke

- 120±5mm

- Scrub frequency

- 0~60cpm

- Contact surface diameter

- F14 ± 0.5mm

- Wiping pressure on the test plate

- 0.06Mpa

- Specimen size

- 200*75mm

- Power

- 220V 50Hz

- Overall Dimensions

- 260*260*340mm

- Weight

- About 20kg

Equipment introduction

Solvent Wipe Resistance Tester is a device used to measure the solvent wipe resistance of coatings. Use a wiping head with a certain speed and wiping pressure (absorbent cotton wetted with a solvent in contact with bread) to wipe back and forth on the surface of the sample. The number of wiping times can be directly read by the counter. According to the number of wiping times required for coating damage, the coating can be evaluated Excellent solvent wipe resistance. Implementation of the standard GB/T23989.

Instructions

1. Unscrew the fastening bolts on the sample fixtures at both ends, place the 75×200mm sample on the phenolic fixing plate, and then tighten the fastening bolts.

2. Take an appropriate amount of absorbent cotton and wrap it on the contact surface of the wiping head, install the hoop, tighten the fixing screws, then take an appropriate amount of absorbent cotton, put it into the inner cavity of the wiping head, and drop an appropriate amount of solvent until the wiping head has solvent oozing out. The wiper head is placed on the slide arm.

3. Plug in the power supply, set the number with the counter, and select the number of times you want to wipe; turn the speed control knob to select the desired wiping speed (60 times/min is recommended, that is, the speed control knob points to MAX).

4. Turn on the power switch of the governor, and the machine starts to work. After reaching the predetermined number of times, the machine stops automatically, and the sample is removed for observation.

5. If you want to stop the machine during operation, you can directly turn off the power switch of the governor, and then turn on the power switch of the governor if you want to continue working.

6. After the machine stops automatically, just press the "Reset" button on the counter, and the machine can run again.

- 1ASTM D7835/D7835M-23《Standard Test Method for Determining the Solvent Resistance of an Organic Coating Using a Mechanical Rubbing Machine》

- 2SJ 20910A-2018《General specification for powder spraying coating》

- 3JB/T 4279.10-2008《Verification procedure for test equipment of enamelled winding wire.Part 10:Tester for resistance to solvents》

- 4GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 5HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 6HG/T 5367.1-2018《Coatings for rail transit vehicles - Part 1: Waterborne coatings》

- 7GB/T 22412-2016《Aluminium-plastic composite panel for ordinary decoration》

- 8ASTM D5402-2019《Standard Practice for Assessing the Solvent Resistance of Organic Coatings Using Solvent Rubs》

- 9GB/T 5211.9-1985《Method for the determination of resistance to solvent of pigments》

- 10GB/T 5211.5-2008《Method for the determination of resistance to materials of pigments》

RJCS

RJCS