LANDTEK CM8821 Coating Thickness Gauge measurement of non-magnetic conductive coatings on ferromagnetic metal substrates

SELANDTEK hot-selling model, measuring thickness up to 1000μm; External probe, magnetic Induction; Low Voltage prompt; USB and Bluetooth data output can be purchased separately.

$236.00/set

PromotionLoading...

Coupon

Model:

Similar products

-

Leeb210 coated Film Thickness Gauge Eletroplating, chemical industry, shipbuilding, light industry, automobile and other fields

Leeb210 coated Film Thickness Gauge Eletroplating, chemical industry, shipbuilding, light industry, automobile and other fields -

IWAVE WH-81 Coating Thickness Gauge magnetic thickness measurement method 0~1250μm$ 165.00SE

IWAVE WH-81 Coating Thickness Gauge magnetic thickness measurement method 0~1250μm$ 165.00SE -

Dual-use Coating Thickness Gauge AMITTARI AC-110AS External thickness probe type, thickness range 0~1250um$ 344.00SE

Dual-use Coating Thickness Gauge AMITTARI AC-110AS External thickness probe type, thickness range 0~1250um$ 344.00SE -

Defelsko PosiTest DFT Ferrous steel Coating Thickness Gauge nonmagnetic coatings$ 604.00SE

Defelsko PosiTest DFT Ferrous steel Coating Thickness Gauge nonmagnetic coatings$ 604.00SE -

LANDTEK CM8822 platings Thickness Gauge measurement of nonconductive coatings on magnetically permeable objects and nonconductive coatings on nonmagnetic metal substrates$ 334.00SE

LANDTEK CM8822 platings Thickness Gauge measurement of nonconductive coatings on magnetically permeable objects and nonconductive coatings on nonmagnetic metal substrates$ 334.00SE

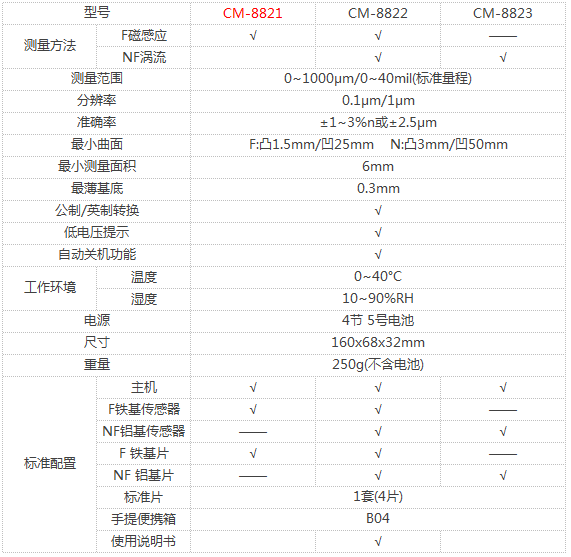

LANDTEK CM8821 Coating Thickness GaugeSPEC

LANDTEK CM8821 Coating Thickness GaugeDetails

LANDTEK CM8821 Coating Thickness GaugePacking list

- SKU

- NB000265

- Measurement principle

- magnetic induction

- Measuring range

- 0 ~ 1000µm

- margin of error

- ±3%

- resolution

- 0.1mm | 1mm

- Minimum radius of curvature

- F: convex 1.5mm; concave 25mm

- thinnest matrix

- 0.3mm

- probe

- F Split Probe

- Power

- 4 * AA battery

- Calibrated Certificate

- without

- Language

- Chinese

- Display screen

- LCD

- supporting software

- without

- Total Weight

- 210G (without battery)

- Complete-built unit size

- 161*69*32mm

- Minimum measurement surface

- F6mm

- Unit display

- μm/mils

- Voltage prompt

- Low Voltage prompt

- Operating Temperature

- 0~40℃

- Optional accessories

- Customizable Range (Large Range Sensors): 0~200um to 18000um

- Relative Humidity

- 10~90%RH

CM8821

Coating Thickness Gauge

LANDTEK hot-selling model, measuring thickness up to 1000μm; External probe, magnetic Induction; Low Voltage prompt; USB and Bluetooth data output can be purchased separately.

Introduction

As the hot-selling model of LANDTEK coating Thickness Gauge, LANDTEK CM8821 coating Thickness Gauge is a magnetic Thickness Gauge using the magnetic principle. It is an economical coating Thickness Gauge for measuring magnetic metal substrates. The thickness of the non-magnetic coating, the measured thickness range is 0~1000 microns. The CM8821 coating Thickness Gauge displays the measured data through the LCD, and has a low Voltage indication function, which can prompt the user to replace the battery in time to avoid low power affecting the life of the Thickness Gauge.

Applications

| Specification model: | CM-8821 |

| Applications: | Magnetic induction coating Thickness Gauge CM-8821 uses a magnetic sensor to measure non-ferromagnetic coatings and coatings on ferromagnetic metal substrates such as steel and iron, such as: paint, powder, plastic, rubber, synthetic materials, phosphating layer, chromium , zinc, lead, aluminum, tin, cadmium, porcelain, enamel, oxide layer, etc. |

Features

CM8821 Coating Thickness Gauge measures the thickness of the non-magnetic coating on the ferromagnetic metal substrate.

Pictures

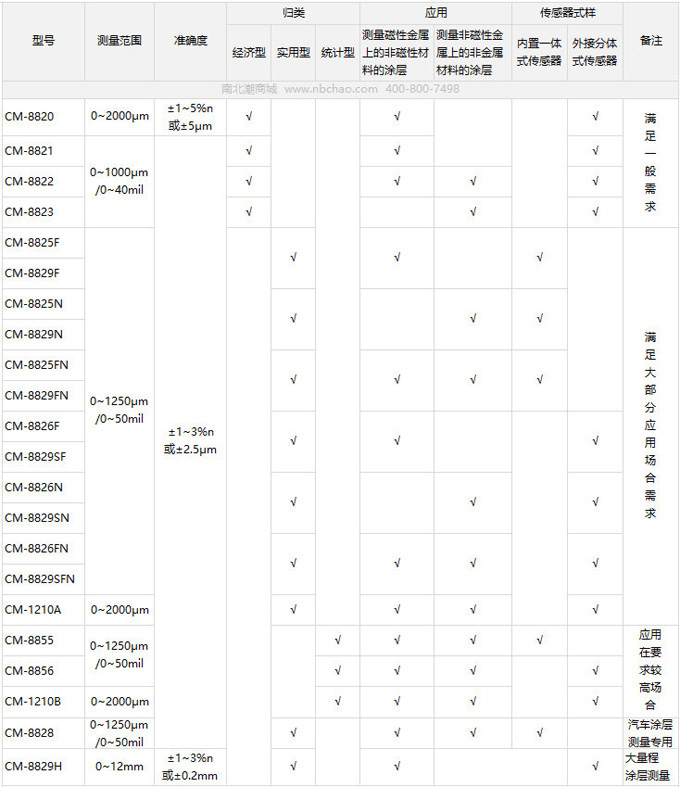

Selection reference chart

selection list

FAQ

QExcuse me, test the phosphating film on the iron base, is there any suitable thickness gauge suggestion here?

A

CM8821 is fine.

QAre both the 8820 and 8821 the same probe?

A

They are all F iron-based probes, but the probes cannot be replaced with each other, nor can the same type. The host and the probe are matched one by one. The replacement needs to be precisely debugged before it can be used, otherwise both sets will not be allowed.

QWhat kind of battery is installed in the coating thickness gauge CM8821?

A

Hello, it has 4 AA batteries.

QHello, what is the measurement range of CM-8821 galvanized coating?

A

Hello, the thickness measurement range of this one is 0~ 1000 microns, which is a magnetic induction thickness gauge.

QDoes the Coating thickness gauge meet the requirements of ISO2178?

A

Model CM8821 Coating thickness gauge

QHello, what is the function of the matching diaphragm and substrate?

A

Hello, Coating thickness gauge CM-8821 is to measure the coating thickness on magnetic metal (F type). The diaphragm is the known coating thickness (calibrated diaphragm CTG-CF).

Then place the diaphragm on the substrate (F-type iron substrate/reference block (iron base) CTG-BS) to measure. The measured reading should be within the range written on the diaphragm. If it is not within the range, adjust the up and down buttons of the machine until the reading is correct. At this time, the machine is successfully calibrated, and then the measured object is measured.

QHow does it work?

A

Hello, CM8821 type thickness gauge has detailed operation instructions in each Encasement list. Since the electronic thickness gauge measurement is very simple, you can also place the thickness gauge flat on the sample after film drying, and take the arithmetic average of the film thickness at each point, which is the average Film thickness value of the film.

QCan CM8821 measure Film thickness of hard chrome layer on metal surface?

A

Hello! CM8821 Coating thickness gauge belongs to Magnetic Induction Coating thickness gauge, which is suitable for measurement of non-magnetic coating/plating on iron metal substrates such as steel and iron (such as paint, powder, plastic, rubber, synthetic materials, phosphating layer, chromium, zinc, lead, tin, porcelain, enamel, oxidation layer, etc.) As long as the chromium layer of your sample is on the surface of ferromagnetic metal substrates such as steel and iron, it can be measured.

QCan this CM8821 thickness gauge be used to measure Coated steel?

A

Coated steel production online commonly used testing equipment needs to meet the inspection requirements of national standards. Therefore, different Coated steel manufacturers have the same testing equipment.

QPlease ask the thickness gauge generally needs, how many times is the appropriate repeability test?

A

In the specific measurement process, the measurement data of the instrument usually fluctuates each time, and the measurement error is too large. Therefore, it is necessary to repeat the measurement readings in each measurement area during measurement. When processing the data, it is necessary to exclude the data with excessive errors. Take the average value of the fluctuation value to better reduce the measurement error caused by the operation and the instrument. Generally speaking, the more times of measurement, the closer the final data is to the accurate value, but for easy operation, generally three to five measurements are made in each measurement area

Standard

- 1HG/T 3240-2007《Micro-computer film-thickness tester》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 4GB/T 42541-2023《Coated steel pipes for gas piping》

- 5GB/T 7991.5-2014《Test method of viterous and porcelain enamels—Part 5:Determination of thickness by electromagnetic mothod》

- 6JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 7GB/T 1727-2021《General methods for preparation of coating films》

- 8HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 9ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 10ISO 2178-2016《Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method》

CM8821

CM8821