LANDTEK CM8825F high-precision Coating Thickness Gauge, integrated magnetic Induction Coating Thickness Gauge

SE-

IWAVE WH-81 Coating Thickness Gauge magnetic thickness measurement method 0~1250μm$ 165.00SE

IWAVE WH-81 Coating Thickness Gauge magnetic thickness measurement method 0~1250μm$ 165.00SE -

DONGRU DR320 Coating Thickness Gauge electromagnetic induction principle for magnetic metal substrate surface platings measurement$ 306.00SE

DONGRU DR320 Coating Thickness Gauge electromagnetic induction principle for magnetic metal substrate surface platings measurement$ 306.00SE -

LANDTEK CM8829F magnetic Thickness Gauge, integrated F magnetic Induction Film Thickness Gauge$ 311.00SE

LANDTEK CM8829F magnetic Thickness Gauge, integrated F magnetic Induction Film Thickness Gauge$ 311.00SE

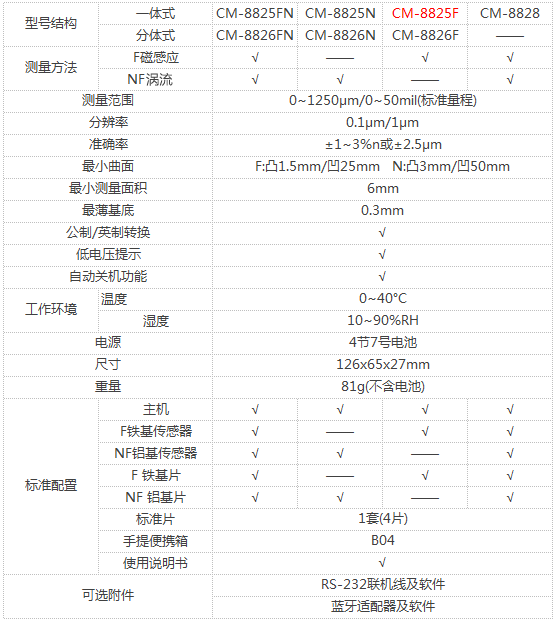

LANDTEK CM8825f Coating Thickness GaugeSPEC

LANDTEK CM8825f Coating Thickness GaugeDetails

LANDTEK CM8825f Coating Thickness GaugePacking list

- SKU

- NB000268

- Measurement principle

- Magnetic Induction

- Measurement range

- 0~1250μm

- margin of error

- ±3%

- Resolution

- 0.1μm|1μm

- Minimum radius of curvature

- F: convex 1.5mm; concave 25mm

- thinnest substrate

- 0.3mm

- probe

- F integrated probe

- icon function

- without

- Power Supply

- 4 * AAA battery

- Calibrated Certificate

- without

- system language

- Chinese

- Display screen

- LCD screen

- supporting software

- without

- Machine Weight

- 81G (without battery)

- Machine size

- 126*65*27mm

- Minimum measurement surface

- Φ6mm

- Unit display

- μm/mils

- Voltage prompt

- Low Voltage prompt

- Operating temperature

- 0~40℃

- Relative Humidity

- 10~90%RH

Introduction

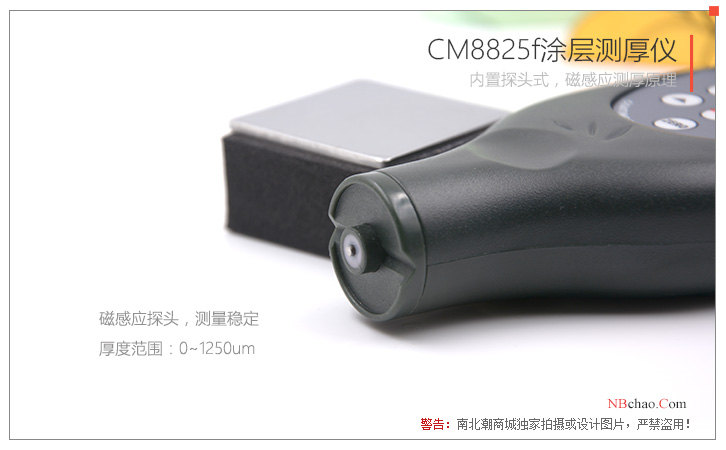

CM8825f Coating Thickness Gauge is a hand-held coating Thickness Gauge with built-in probe integrated structure design, the shape and structure design is ergonomic, and the holding part has a concave part to meet the two fingers to hold the Thickness Gauge more steadily, preventing jitter or sliding during measurement.The CM8825f Coating Thickness Gauge is a magnetically inductive coating Thickness Gauge for measuring the thickness of non-magnetic conductive overlays on magnetically conductive materials, measuring quickly and accurately, and transmitting operating data by connecting to a PC.

Application examples

LANDTEK CM8825f coating Thickness Gauge has been used for the thickness measurement of electroplating, paint layer, enamel layer, aluminum tile, copper tile, babbitt alloy tile, phosphate layer, paper, and can also be used for thickness measurement of hull paint and underwater structural parts attachment.

Product Applications

LANDTEK CM8825F Coating Thickness Gauge uses magnetic sensors to measure non-ferromagnetic coatings and coatings on ferromagnetic metal substrates such as steel and iron, such as paint, powder, plastic, rubber, synthetic materials, phosphating layer, chromium, zinc, lead, aluminum, tin, cadmium, porcelain, enamel, oxide layer, etc.

Actual picture of the product

Features

*CM8825f Coating Thickness GaugeThere are two types of measurement options: single and continuous.

* Metric/Imperial unit conversion.

* It has the functions of manual shutdown, automatic shutdown and under-Voltage prompt.

* Automatic memory of calibration values and automatic identification of the material of the tested substrate.

* There is a buzzer prompt sound during operation, and the buzzer does not sound when continuous measurement.

* CM8825f Coating Thickness GaugeRS-232C data cable and software are used to communicate with the PC.

* Optional Bluetooth data output options are also available.

* CM8825f Coating Thickness GaugeIt is suitable for one-handed operation, has a "large probe", and the large contact surface has better stability, and the results are accurate and repeatable.

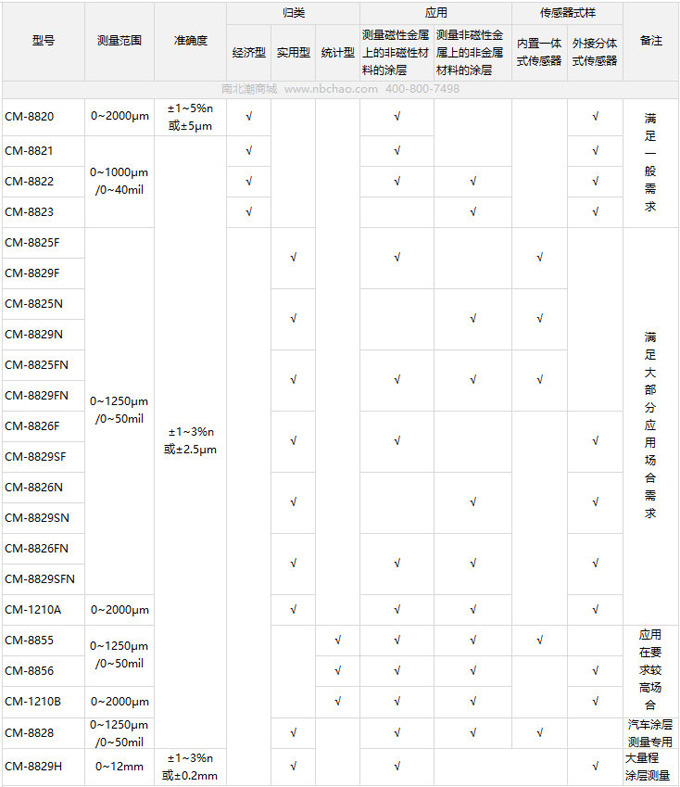

Selection guide

LANDTEK Coating Thickness Gauge Selection List

- 1HG/T 3240-2007《Micro-computer film-thickness tester》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3GB/T 1727-2021《General methods for preparation of coating films》

- 4HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 5ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 6ISO 2178-2016《Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method》

- 7ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 8ISO 19840-2012《Paints and varnishes Corrosion protection of steel structures by protective paint systems》

- 9ASTM E376-2019《Standard Practice for Measuring Coating Thickness by Magnetic-Field or Eddy Current (Electromagnetic) Testing Methods》

- 10ISO 2808-2019《Paints And Varnishes - Determination Of Film Thickness》

CM8825f

CM8825f