DONGRU DR6000 Anticorrosive layer Thickness Gauge 0~6000μm

SE-

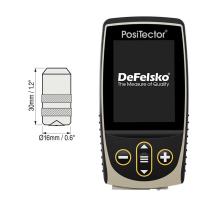

Defelsko PosiTector 6000 FTS1 Steel plate Coating Thickness Gauge Split probe type$ 1108.00SE

Defelsko PosiTector 6000 FTS1 Steel plate Coating Thickness Gauge Split probe type$ 1108.00SE -

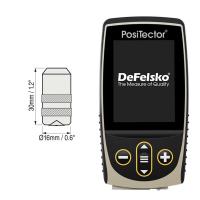

Defelsko PosiTector 6000 FT1 Portable platings Thickness Gauge, integrated magnetic Thickness Gauge$ 992.00SE

Defelsko PosiTector 6000 FT1 Portable platings Thickness Gauge, integrated magnetic Thickness Gauge$ 992.00SE -

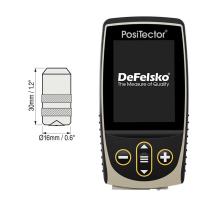

Defelsko PosiTector 6000 FT3 Coating Thickness Gauge$ 1497.00SE

Defelsko PosiTector 6000 FT3 Coating Thickness Gauge$ 1497.00SE -

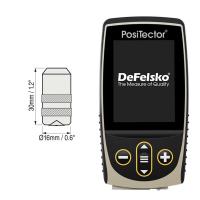

Defelsko PosiTector 6000 FTS3 Coating Thickness Gauge Advanced thick coating probe$ 1612.00SE

Defelsko PosiTector 6000 FTS3 Coating Thickness Gauge Advanced thick coating probe$ 1612.00SE

DongRu DR6000 Anti-corrosion layer Thickness GaugeSPEC

DongRu DR6000 Anti-corrosion layer Thickness GaugeDetails

DongRu DR6000 Anti-corrosion layer Thickness GaugePacking list

- SKU

- NB026888

- Measurement principle

- Magnetic Induction

- Measurement range

- 0 ~ 6000μm

- margin of error

- ±3%

- Resolution

- 0.1mm | 1mm

- Minimum measurement surface

- F16mm

- Minimum radius of curvature

- Convex 5mm; Concave 25mm

- thinnest matrix

- 0.4mm

- Power

- Three (7) alkaline batteries

- Operating temperature

- 0℃-50℃

- Relative Humidity

- 20~90%RH

- Total Weight

- 100g

- Complete-built unit size

- 130*70*24mm

- Operating Environment

- Temperature: 0 ℃ -60 ℃, Humidity: 20% RH - 90% RH, use in environment without strong magnetic field

- Language

- Chinese, English

- Display screen

- 2.3-Inch large color screen and large font size display

- Shutdown method

- Manual/Automatic

- Unit display

- μm / Thousand

- Calibrated mode

- Zero point calibrated, two point calibrated, multi point calibrated

- Statistical function

- MAX Maximum (MAX), MIN Minimum (MIN), Average (MEA), Number of measurements (No)

- data storage

- It can be stored in 10 groups, 200 in each group, and a total of 2000 data can be stored

Introduction

DR6000 Coating Thickness Gauge is a professional non-destructive testing instrument for measuring the thickness of coated coatings on the surface of magnetic metal materials. Conforms to the national GB/T 4956-2003 standard, adopts the principle of magnetic thickness measurement, and can quickly and non-destructively measure the thickness of non-magnetic coatings (galvanized, chrome, indium, enamel, rubber, etc.) on magnetic metal substrates (such as: steel, iron) Powder, paint, electrophoresis, enamel, plastic spraying, paint, anti-corrosion and fire-proof coating, etc.), the instrument has a precise and firm structure, good repeatability, excellent performance, easy to use, and convenient to carry.

Applications: Widely used in coating industry, manufacturing industry, metal processing industry, chemical industry, commodity inspection and other testing fields.

Features

Large range 0-6000um

Simple operation, fast test speed, good sensitivity and high measurement accuracy

Alloy probe, durable and precise

There are two measurement methods: continuous measurement and single measurement

There are four statistical functions: maximum value (MAX), minimum value (MIN), average value (MEA), measurement times (No)

Large-capacity storage, can be stored in 10 groups, 200 in each group, and can store 2000 data in total

Stored data store view delete function

Three calibration methods: zero point calibration, two-point calibration, multi-point calibration

Upper and lower limit alarm function (can be set in single measurement mode)

The operation process is marked by a beep (in single measurement mode)

Automatic identification of ferrous and non-ferrous substrates

Metric and imperial conversion μm/Mil

Sunlight mode (used under strong light)

Chinese and English bilingual version

2.3-inch large color screen large font size display

Manual/automatic shutdown function

Bluetooth synchronous data transmission function (customized)

- 1Application of QNIX Thickness Gauge in coated Film thickness measurement

- 2What is a metal substrate? How does it affect coating thickness measurements?

- 3Application of Scanning Probe Thickness Gauge Technology in Coating Thickness Measurement

- 4Coating Thickness Gauge for coated Film thickness measurement in vehicle evaluation

- 5Concept and basic knowledge of coating Thickness Gauge

- 6Application of QNix Coating Thickness Gauge in coating Film thickness measurement

- 7How to choose a portable Thickness Gauge?

- 8Application of Paint Coating Thickness Gauge in Measuring Refractory Coating on Steel Pipe

- 9Coating Thickness Gauge selection guide

- 10Film coating thickness measurement in industrial painting and cissing coating

- 1HG/T 3240-2007《Micro-computer film-thickness tester》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 4GB/T 42541-2023《Coated steel pipes for gas piping》

- 5GB/T 13912-2020《Metallic coatings—Hot dip galvanized coatings on fabricated iron and steel articles—Specifications and test methods》

- 6GB/T 7991.5-2014《Test method of viterous and porcelain enamels—Part 5:Determination of thickness by electromagnetic mothod》

- 7JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 8GB/T 1727-2021《General methods for preparation of coating films》

- 9HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 10SY/T 0315-2013《Technological specification of external fusion bonded epoxy coating for steel pipeline》

DR6000

DR6000