ZKHS GDW-100B Temperature Cycling Test Chamber -20 ℃~ 150 ℃

SE-

ZKHS GDS-100B high-low temperature Humidity Test Chamber -20~150 ℃/100L$ 5976.00SE

ZKHS GDS-100B high-low temperature Humidity Test Chamber -20~150 ℃/100L$ 5976.00SE -

KESIONOTS high and low temperature environmental testing machine KS-OTS-HD80LD temperature control -20 ℃~ 150 ℃$ 4238.00SE

KESIONOTS high and low temperature environmental testing machine KS-OTS-HD80LD temperature control -20 ℃~ 150 ℃$ 4238.00SE -

HZAOC GDJW-100A Temperature Cycling Test Chamber -20 ℃~ 150 ℃/100L$ 5678.00SE

HZAOC GDJW-100A Temperature Cycling Test Chamber -20 ℃~ 150 ℃/100L$ 5678.00SE -

BENTING CBGDW-100L low/high Temperature Test Chamber -20 ℃/100L

BENTING CBGDW-100L low/high Temperature Test Chamber -20 ℃/100L -

BENTING CBGDW-80L low/high Temperature Test Chamber -20 ℃/80L

BENTING CBGDW-80L low/high Temperature Test Chamber -20 ℃/80L

ZKHS GDW-100B Temperature Cycling Test ChamberSPEC

ZKHS GDW-100B Temperature Cycling Test ChamberDetails

ZKHS GDW-100B Temperature Cycling Test ChamberPacking list

- SKU

- NB026929

- Interior size

- 450*450*500mm

- Temperature range

- B:-20~150℃

- Temperature fluctuation

- ≤±0.5℃

- Heating rate

- -20→100℃≈35min

- Cooling rate

- 25~-40℃≈50min

- display

- Large screen touch screen temperature and humidity control instrument

- Accuracy range

- Setting Accuracy: temperature ± 0.1 ℃, indication Accuracy

- Temperature transducer

- Platinum resistance PT100Ω/MV

- Heating system

- Fully independent system, nickel-chromium alloy electric heating heater

- Refrigeration system

- Original French "Taikang", fully enclosed air-cooled compression refrigeration method

- Circulatory system

- Temperature-resistant and low-noise air-conditioned motor, multi-leaf centrifugal wind turbine

- Enclosure Material

- A3 steel plate electrostatic spray treatment

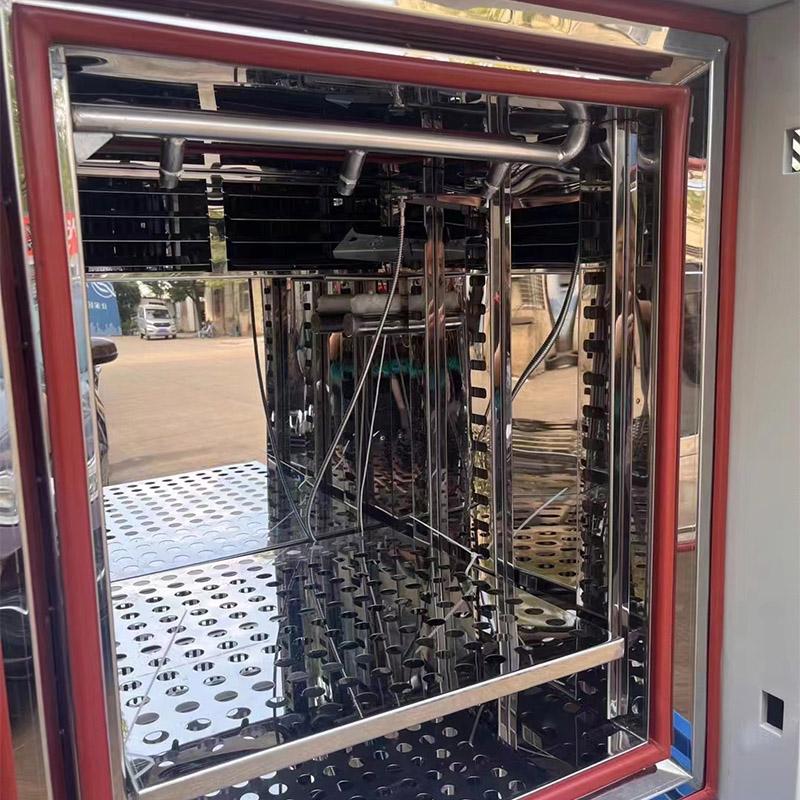

- Inner chamber material

- SUS304 stainless steel high quality mirror steel plate

- Thermal insulation material

- Polyurethane Rigid Foam, Ultrafine Glass Fiber Cotton

- Door frame insulation

- Double Layer High and Low Temperature Conditioning Silicone Rubber Door Seal

- Timer

- 0~9999 M, H adjustable

- Safety Devices

- Leakage, short circuit, over temperature, motor overheating, compressor overVoltage, overload, overcurrent protection

- Power

- AC280V ± 10% AC380V ± 10% 50Hz three-phase five-wire system

- Environment temperature

- 5~30℃

- Environment humidity

- ≤85%R.H

- Temperature Uniformity

- ≤±2℃

Applications

◆This product is suitable for aviation, aerospace products, information electronics, instrumentation, materials, electrical engineering, electronic products, and various electronic components to test their various performance indicators in high-low temperature environments.

Box structure

◆The box body is processed by CNC machine tools, with beautiful and elegant appearance, and adopts non-reactive handles, which are easy to operate.

◆The inner tank of the box is made of imported high-grade stainless steel (SUS304) mirror panel, and the outer shell of the box is made of A3 steel plate sprayed with plastic, which increases the appearance texture and cleanliness.

◆The large observation window is equipped with a lighting lamp to keep the inside of the box bright, and the built-in tempered glass in the heating element is used to clearly observe the situation inside the box at any time.

◆The test hole with a diameter of 50mm is equipped on the left side of the cabinet, which can be used for external test power lines or signal lines.

Control System

◆Temperature control adopts "7.0" large-screen touch screen temperature and humidity control instrument, which is easy to operate and set.

◆After the data and test conditions are input, the controller has a locking function to avoid changing the temperature value by human touch.

◆It has the function of PID automatic calculation, which can immediately correct the temperature change conditions and make the temperature control more accurate and stable.

Refrigeration and air circulation system

◆Refrigerator adopts French original "Taikang" fully enclosed compressor unit.

◆The refrigeration system adopts unit or binary low temperature loop system design.

◆Multi-blade air blower is used for strong air circulation, avoiding any dead angle, and can make the temperature distribution in the test area even.

◆The wind circuit is designed for air circulation and air return. The wind pressure and wind speed are in line with the test standards, and it can make the temperature stabilize quickly when the door is opened.

◆Heating up, cooling down, the system is completely independent and effective, reducing test costs, increasing life, and reducing failure rates.

Standards

Strictly refer to: GB2423.1-2008 test A "high temperature test method", GB2423.2-2008 test B "low temperature test method" GJB150A.3, GJB150A.4 and other related standards design and manufacture.

Series selection

model | GDW-100 | GDW-225 | GDW-500 | GDW-800 | GDW-010 |

Inner Dimensions DXWXH mm | 450X450X500 | 500X600X750 | 700X800X900 | 800X1000X1000 | 1000X1000X1000 |

temperature range | A: 0℃~150℃ B: -20℃~150℃?? C: -40℃~150℃ D: -60℃~150℃ E: -70℃~150℃ | ||||

Fluctuation/Uniformity | ≤±0.5℃/≤±2℃ | ||||

Heating time | -20℃~100℃ for about 35min | -40℃~100℃about 45min | -70℃~100℃about 55min | ||

cooling time | 25℃~-40℃about 50min | 25℃~-60℃about 65min | 25℃~-70℃ for about 80min | ||

controller | Large-screen touch screen temperature and humidity control instrument | ||||

Accuracy range | Setting accuracy: temperature ±0.1°C, indication accuracy | ||||

Temperature Sensor | Platinum resistance PT100Ω/MV | ||||

Heating system | Fully independent system, nickel-chromium alloy electric heating heater | ||||

Cooling System | Original French "Taikang", fully enclosed air-cooled compression refrigeration method | ||||

circulatory system | Temperature-resistant low-noise air-conditioning motor, multi-blade centrifugal wind wheel | ||||

Enclosure Material | A3 steel plate electrostatic spray treatment | ||||

Inner box material | SUS304 stainless steel good mirror plate | ||||

Insulation material | Polyurethane rigid foam, superfine glass fiber cotton | ||||

door frame insulation | Double-layer high-low temperature aging resistant silicone rubber door seal | ||||

Test time | 0~9999 M, H adjustable | ||||

Standard configuration | 1 set of multi-layer heating and frosting with lighting glass window, 2 test sample racks, 1 test lead hole φ50mm | ||||

safety protection | Leakage, short circuit, over temperature, motor overheating, compressor overpressure, overload, overcurrent protection | ||||

Voltage | AC280V±10% AC380V±10% 50Hz Three-phase five-wire system | ||||

Ambient temperature | 5℃~+30℃ ≤85%RH | ||||

- 1Application of low/high Temperature Test Chamber in high-low temperature resistance test of alarm

- 2Application of low/high Temperature Test Chamber in high-low temperature resistance test of toys

- 3Low/high Temperature Test Chamber to test the high-low temperature resistance of automobile power battery

- 4Application of low/high Temperature Test Chamber in high-low temperature resistance test of wiper

- 5Application of low/high Temperature Test Chamber in high-low temperature resistance test of conveyor belt

- 6Low/high Temperature Test Chamber for high-low temperature resistance test of wine cellars

- 7Application of high-low Temperature Test Chamber in component industry

- 1GB/T 2424.7-2024《Environmental testing—Part 3: Supporting documentation and guidance—Measurements in temperature chambers for tests A (Cold) and B (Dry heat) (with load)》

- 2JB/T 4278.8-2011《Verification procedure for test equipment of rubber plastic wire and cable.Part 8: Low temperature test oven》

- 3JG/T 25-2017《Test method for temperature change resistance of architectural coatings》

- 4GB/T 9979-2005《Guide rule of test for mechanical properties of fiber-reinforced plastics at elevated and reduced temperatures》

- 5GB/T 23711.2-2019《Test method for pressure vessels lined with plastics—Part 2:Low-temperature testing》

- 6GB/T 10590-2006《Specifications for high and low temperature/low air pressure testing chambers》

- 7GB/T 33861-2017《Testing method of energy efficiency for temperature Test Chambers》

- 8GB/T 10592-2023《Specifications for high/low temperature testing chambers》

- 9GB/T 2423.63-2019《Environmental testing—Part 2:Test methods—Test: combined temperature(cold and heat)/low air pressure/vibration(mixed mode)》

- 10 10590-2006《Specifications for high and low temperature / low air pressure testing chambers》

GDW-100B

GDW-100B