ZKHS HS-225A Constant Temperature and Humidity Tester RT + 10~150 ℃/225L

SEZKHS HS-225A Constant temperature and Humidity ChamberSPEC

ZKHS HS-225A Constant temperature and Humidity ChamberDetails

ZKHS HS-225A Constant temperature and Humidity ChamberPacking list

- SKU

- NB026975

- Interior size

- 500*600*750mm

- Temperature range

- RT+10~150°C

- Humidity control range

- 85~98%R.H

- Temperature fluctuation

- ≤±0.5℃

- Humidity Deviation

- +2、-3%R.H

- Heating rate

- 0→100℃≈35min

- Timer

- 0~9999 M, H adjustable

- Controller

- Using (7.0 inch) large screen screen, the screen operation is simple, and the program editing is easy.

- temperature control Accuracy

- ±0.1℃

- Temperature transducer

- Platinum resistor. PT100Ω/MV

- Heating system

- Fully independent system, nickel-chromium alloy electric heating heater

- Humidification system

- Built-in isolated, all stainless steel shallow surface evaporative humidifier

- Dehumidification system

- Adopt evaporator coil dewpoint temperature laminar flow contact dehumidification method

- Water supply system

- Humidified water supply adopts automatic control

- Refrigeration system

- Fully enclosed air-cooled compression refrigeration method, original French "Taikang" unit

- Circulatory system

- Temperature-resistant and low-noise air-conditioned motor, multi-leaf centrifugal wind turbine

- Enclosure Material

- A3 steel plate electrostatic spray treatment

- Inner box material

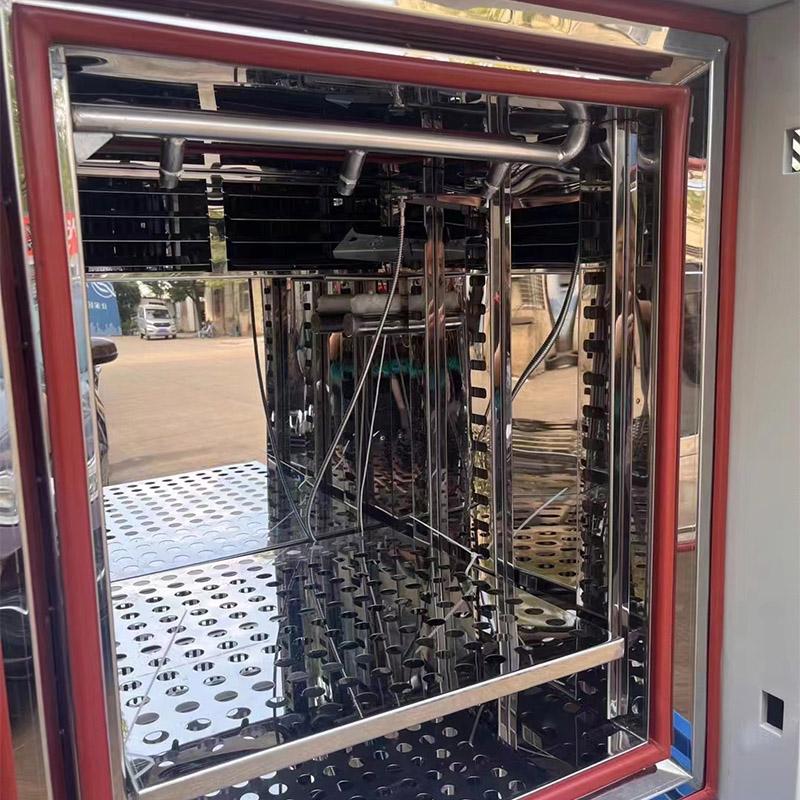

- SUS304 stainless steel high quality mirror steel plate

- Thermal insulation material

- Polyurethane Rigid Foam/Ultrafine Glass Fiber Cotton

- Door frame insulation

- Double Layer High and Low Temperature Conditioning Silicone Rubber Door Seal

- Total power

- 4.0KW

- Standard configuration

- 1 set of illuminated Glass window, 2 test racks, 1 test lead hole φ50mm

- Safety Devices

- Leakage, short circuit, over temperature, water shortage, motor overheating, compressor overVoltage, overload, overcurrent protection

- Power

- AC220V ± 10% 50Hz AC380V ± 10% 50Hz three-phase five-wire system

- Environment temperature

- 5~30℃

- Environment humidity

- ≤85%R.H

- Temperature Uniformity

- ≤±2℃

- Cooling rate

- 100→0℃≈45min

- Humidity Control Accuracy

- ±1%R.H

Applications

◆The product is suitable for testing equipment required in aviation, automobiles, home appliances, scientific research and other fields, and is used to test and determine the parameters and performance of electrical, electronic and other products and materials after changing the temperature environment of high temperature, low temperature, humidity heat or constant test.

Cabinet structure

◆The box body is processed and formed by CNC machine tools, the shape is beautiful and generous, and the non-reaction handle is adopted, which is easy to operate.

◆The inner liner of the box is made of imported stainless steel (SUS304) mirror panel argon arc welding, and the shell of the box is sprayed with A3 steel plate.

◆ Adopt (7.0 inches) large screen screen, the screen operation is simple, and the program editing is easy.

◆ Large observation window with lighting to keep the box bright, and double glazing is used to clearly observe the situation in the box at any time.

◆ It is equipped with an independent temperature limit alarm system, which will automatically interrupt when the limit temperature is exceeded, so as to ensure the safe operation of the experiment without accidents.

◆ Optional Recorder, the printer can print and record the set parameters and scan out the temperature and humidity change curve, 4~20mA standard signal.

◆The left side of the box is equipped with a test hole with a diameter of 50mm.

Refrigeration and air circulation system

◆ The refrigerator adopts the original French "Taikang" fully enclosed compressor unit.

◆ The multi-wing blower is used to supply air with strong air supply circulation to avoid any dead angles, which can make the temperature distribution in the test area uniform.

◆ The air path is designed to circulate the air outlet and return air, and the wind pressure and wind speed meet the test standards, and the temperature can stabilize quickly at the moment of opening the door.

◆ Heating, cooling, and the system is completely independent and effective, reducing the cost of testing, increasing the life expectancy, and reducing the failure rate.

Meets standards

Strictly refer to: GB/T5170.5-2008, GB/T10586-2006, GB/T2423.1-2008, GB/T2423.3-2006 and other relevant standards for design and manufacturing.

Series selection

Model | HS-100 | HS-225 | HS-500 | HS-800 | HS-010 |

Inner dimensions | 450X450X500 | 500X600X750 | 700X800X900 | 800X1000X1000 | 1000X1000X1000 |

Temperature range | A:RT+10℃~150℃ B:0℃~150℃ | ||||

Humidity range | A:85~98%R.H B:30~98%R.H | ||||

Fluctuation/uniformity | ≤±0.5℃、≤±2℃ | ||||

Humidity deviation | +2、-3%R.H | ||||

Rise and cool down time | 0°C~100°C for about 35min, 100°C~0°C for about 45min | ||||

Duration of the trial | 0~9999 M, H adjustable | ||||

controller | It adopts a large screen (7.0 inches), which is easy to operate and easy to edit. | ||||

Accuracy range | Setting accuracy: temperature±0.1°C, humidity±1%R.H | ||||

Temperature and humidity sensors | Platinum resistors. PT100Ω/MV | ||||

Heating system | Fully self-contained, nickel-chromium alloy electrically heated heater | ||||

Humidification system | Built-in isolated, all-stainless steel shallow surface evaporative humidifier | ||||

Dehumidification system | The dew point temperature laminar flow contact dehumidification method of evaporator coil is adopted | ||||

water supply system | The humidified water supply is automatically controlled | ||||

Refrigeration system | Fully enclosed air-cooled compression refrigeration method, original French "Taikang" unit | ||||

circulatory system | Temperature-resistant and low-noise air-conditioning motor, multi-leaf centrifugal wind wheel | ||||

Enclosure Material | A3 steel plate electrostatic spraying treatment | ||||

Inner box material | SUS304 stainless steel good mirror steel plate | ||||

Insulation material | Polyurethane rigid foam/ultra-fine glass fiber foam | ||||

Door frame insulation | Double-layer silicone rubber door sealing strip resistant to high-low temperature aging | ||||

Total power | 4.0KW | 5.0KW | 6.0KW | 7.5KW | 9.0KW |

Standard configuration | It is equipped with 1 set of lighting glass windows, 2 sample racks, and 1 test lead hole φ50mm | ||||

Security | Leakage, short circuit, overtemperature, water shortage, motor overheating, compressor overpressure, overload, overcurrent protection | ||||

Supply Voltage | AC220V±10%50Hz AC380V±10% 50Hz three-phase five-wire system | ||||

Use ambient temperature | 5℃~+30℃ ≤85%R.H | ||||

- 1How to solve the problem after the failure of the constant temperature and humidity Test Chamber is found?

- 2How to solve the leakage of large constant temperature and humidity Test Chamber?

- 3Troubleshooting method of constant temperature and humidity Test Chamber

- 4How to do a good job in the regular maintenance and cleaning of the constant temperature and humidity Test Chamber?

- 5What should be paid attention to when using a constant temperature and humidity Test Chamber?

- 6What should be paid attention to in the maintenance of the constant temperature and humidity Test Chamber?

- 7How to use the constant temperature and humidity Test Chamber to save energy and electricity?

- 8Introduction of alarm function of constant temperature and humidity Test Chamber

- 9System introduction of constant temperature and humidity Test Chamber

- 10What is the principle of the walk-in constant temperature and humidity Test Chamber? What are the method steps?

- 1IEC 《Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady state》

- 2IEC 《Environmental testing – Part 2-67: Tests – Test Cy: Damp heat, steady state, accelerated test primarily intended for components》

- 3IEC 《Electricity metering equipment - Dependability Part 31-1: Accelerated reliability testing - Elevated temperature and Humidity》

- 4BSI 《Electricity metering equipment - Dependability - Part 31-1: Accelerated reliability testing - Elevated temperature and humidity》

- 5ASTM 《Standard Practice for Heat and Humidity Aging of Oxidatively Degradable Plastics》

- 6ASTM 《Standard Practice for Heat and Humidity Aging of Oxidatively Degradable Plastics》

- 7GB/T 2423.34-2024《Environmental testing—Part 2:Test methods—Test Z/AD: Composite temperature/humidity cyclic test》

- 8JJF 1564-2016《Calibration Specification for Temperature and Humidity Standard Chambers》

- 9JJF 1270-2010《Calibration Specification for Temperature/Humidity/Vibration Combined Environmental Testing System》

- 10JJF 1101-2019《Calibration Specification for Environmental Testing Equipment for Temperature and Humidity Parameters》

HS-225A

HS-225A