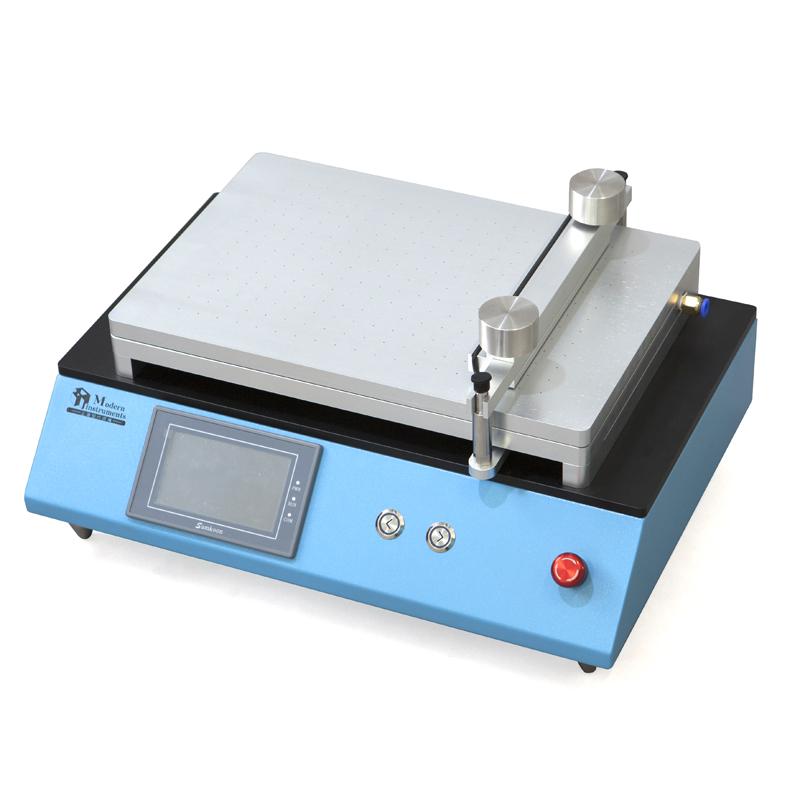

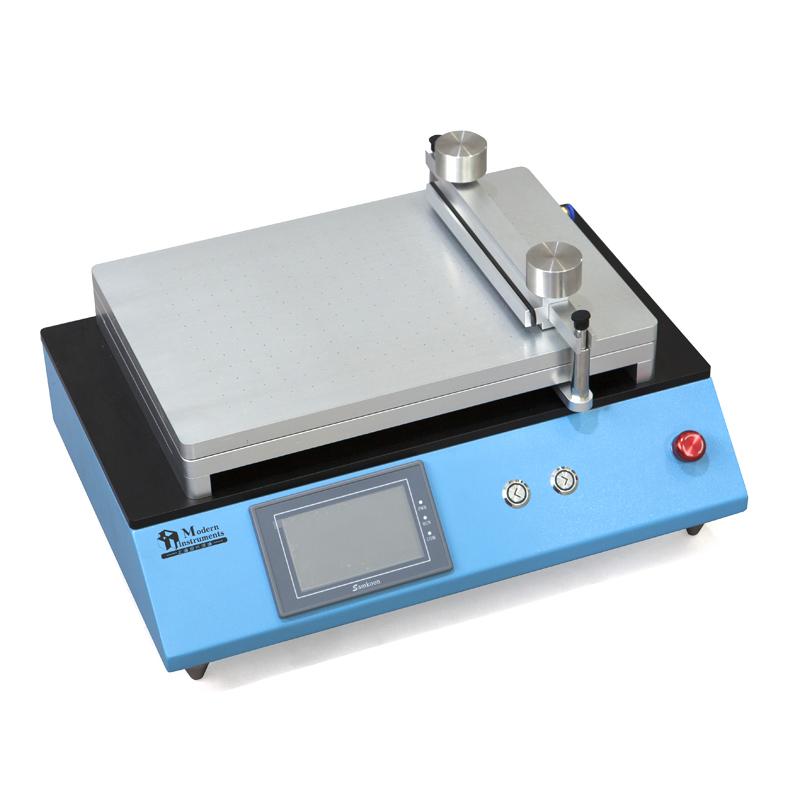

MODERNER FAA-V Miniature Automatic Film Applicator with External Vacuumpump

SE-

HuiNuo TM2200 Drawdown blade Vacuum chuck Lab Film Applicator Flat coater$ 3802.00SE

HuiNuo TM2200 Drawdown blade Vacuum chuck Lab Film Applicator Flat coater$ 3802.00SE -

HuiNuo TM2200Pro/03 drawdown blade vacuum adsorption high-precision coater effective Spreader area 400 * 400mm$ 5356.00SE

HuiNuo TM2200Pro/03 drawdown blade vacuum adsorption high-precision coater effective Spreader area 400 * 400mm$ 5356.00SE -

HuiNuo TM 2200/03 drawdown blade vacuum adsorption small coater effective Spreader area 400 * 400mm$ 4579.00SE

HuiNuo TM 2200/03 drawdown blade vacuum adsorption small coater effective Spreader area 400 * 400mm$ 4579.00SE -

CHINA TBJ-X1-DJ8 Detachable drawdown blade Vacuum adsorption Film Applicator Effective area 500 * 600mm$ 6289.00SE

CHINA TBJ-X1-DJ8 Detachable drawdown blade Vacuum adsorption Film Applicator Effective area 500 * 600mm$ 6289.00SE -

HUINUO TM2200Pro/02 drawdown blade vacuum adsorption Small Film Applicator Effective area 500 * 600mm$ 5978.00SE

HUINUO TM2200Pro/02 drawdown blade vacuum adsorption Small Film Applicator Effective area 500 * 600mm$ 5978.00SE

Moderner AFA-V (Vacuum) Automatic Film ApplicatorSPEC

Moderner AFA-V (Vacuum) Automatic Film ApplicatorDetails

Moderner AFA-V (Vacuum) Automatic Film ApplicatorPacking list

- SKU

- NB027134

- Coating table configuration

- Vacuum coating table

- Push rod movement displacement

- 2-5-10-15-20-25-50-75-100-150-200mm/s

- Push rod movement displacement

- 0~250Mm (25mm interval)

- Effective coating Area

- 380*254mm

- Vacuum chuck size

- 288*192mm

- Host Power Supply

- 110/220V 50/60Hz

- Dimensions

- 470*350*215mm

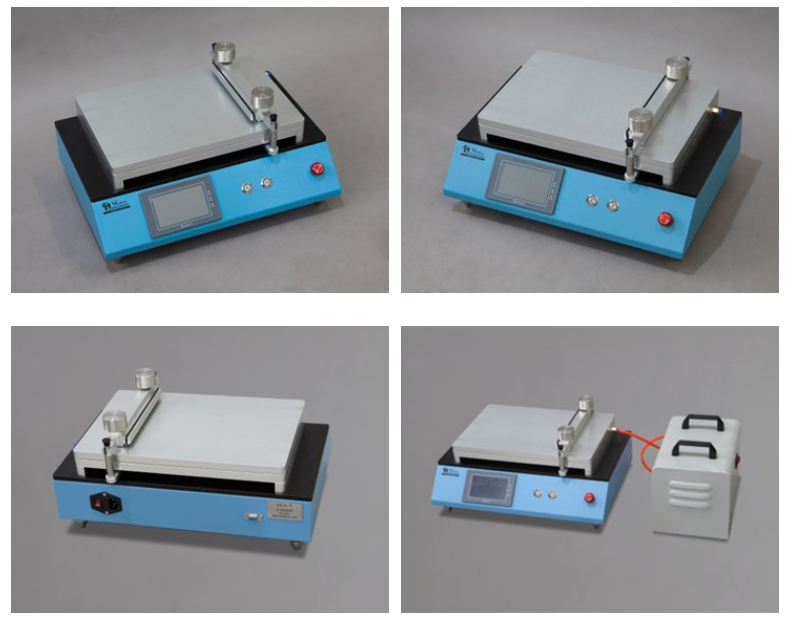

AFA series automatic film coating machine adopts electric push rod to realize the coating movement of Wet Film Applicator or wire bar, effectively avoiding the instability of manual coating. This machine adopts single-chip microcomputer control technology; the touch screen displays, selects the speed and displacement of the left and right lines, and displays the actual moving distance of the coating in real time during operation; the coating rack can be returned by electric or manual; the operation interface is simple and clear, which is very convenient for the operator to use ; For ease of use, left and right start/stop mechanical buttons and emergency stop mechanical buttons are also added.

This machine has detachable "vacuum coating table" and "fixture coating table" two optional configurations for customers to choose when ordering.

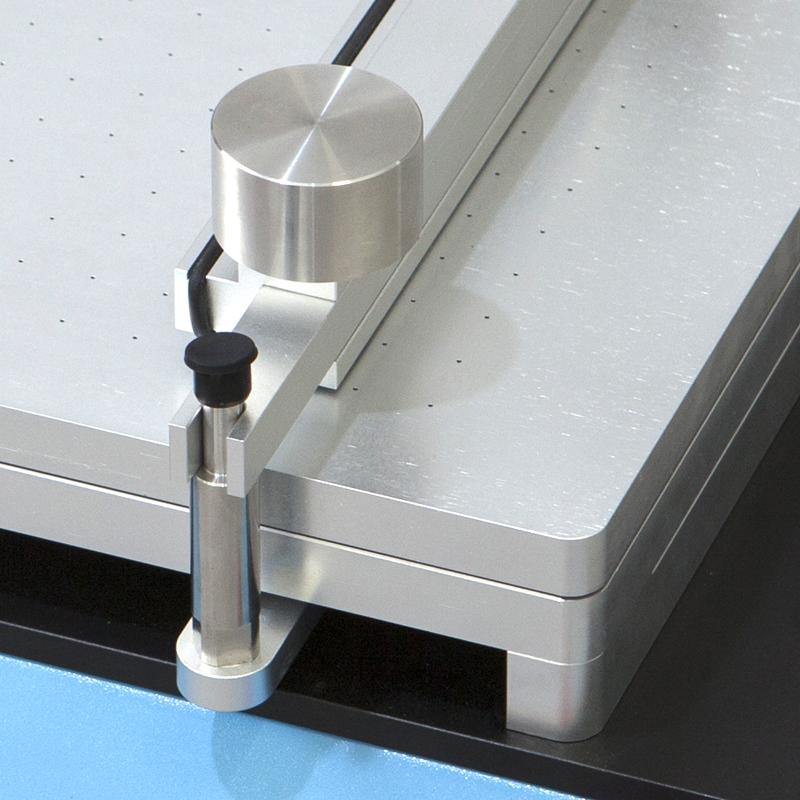

The vacuum coating table uses an external Vacuum Pump (optional). The vacuum coating table panel is positioned by positioning pins, which can be easily removed for cleaning.

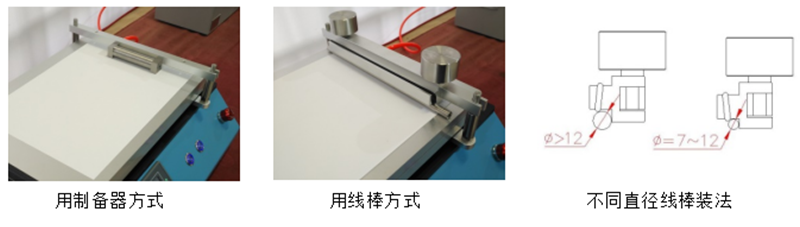

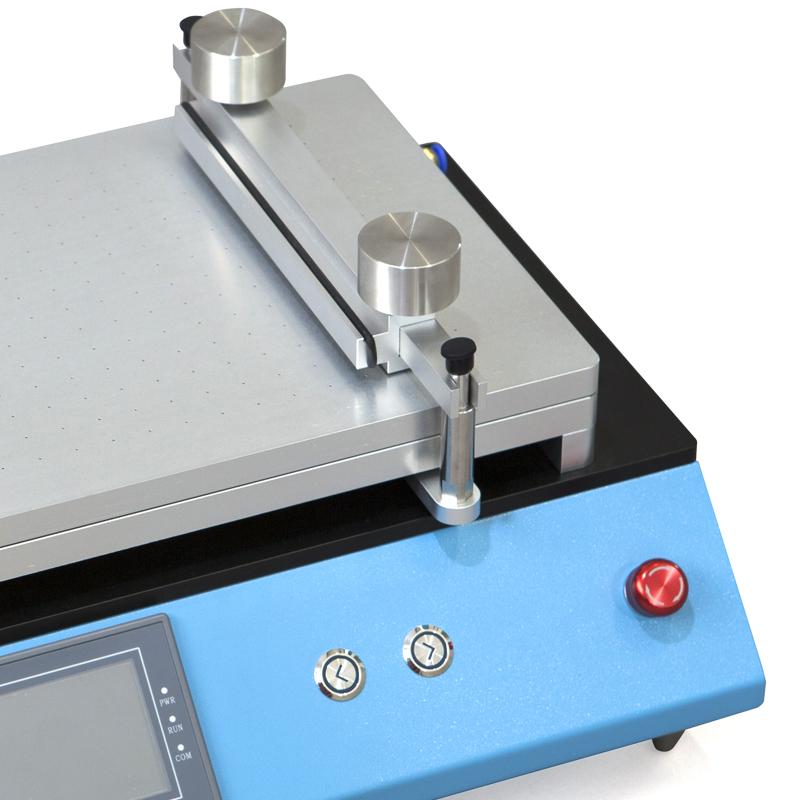

The coating push rod of this machine has been improved, which can be used for Wet Film Applicator, and it can also be used for various specifications of wire rods after installing wire rod push racks. The wire rod push frame can be equipped with a counterweight to meet the pressure requirements during wire rod coating.

NOTE: Wet film prep and wire rods are sold separately.

The AFA series automatic film coating machine is used in the testing process of chemical raw materials. Users should establish appropriate safety and health protection measures and determine rules and regulations according to relevant safety regulations before use. Safety issues related to contact with chemical raw materials should be established by the user and are not within the scope of this manual.

AFA series model

| model | AFA-V | AFA-VI | |

| Coating station configuration | Vacuum coating table | Fixture Coating Table | Vacuum coating table |

| Push rod moving speed | 2-5-10-15-20-25-50-75-100-150-200mm/s | ||

| Push rod movement displacement (interval 25mm) | 0~250mm | 0~400mm | |

| Coating table (length x width) | 380×254mm | 470×254mm | 530×350mm |

| Vacuum hole distribution (length x width) | 288×192mm | - | 400×288mm |

| using electric | 110/220V 50/60Hz | ||

| Host appearance (length × width × height) | 470×350×215mm | 620×450×230mm | |

Note: When the displacement of the push rod is set to 0, the moving distance is controlled by the limit switches at both ends; when the displacement of the push rod is set to less than 25, it will automatically turn to 25.

Instructions

1. Place the instrument on a stable workbench, and adjust the foot of the instrument to make the instrument stable. The instrument should be kept away from complex electromagnetic interference sources.

2. Put the power switch on the back of the chassis to the off position, then plug in the power cord (located at the back of the chassis) and turn on the power.

3. Connect the suction pipe of the Vacuum Pump to the vacuum coating table (the Vacuum Pump can be started to check whether the adsorption of the vacuum coating table is normal).

4 Install the coating push rod on the bracket, and the installed coating push rod can be pushed by hand.

5. After completing the above preparations, turn on the power switch and it can be used.

6. Parameter selection and operation can be realized through the touch screen.

7. The "<" and ">" mechanical buttons can also be used to start and stop the instrument running left and right (the function is the same as the touch screen), and the instrument stops running by pressing any mechanical button during the operation of the instrument. Note: When the touch screen is running, the "<" or ">" button you click will change to "□", and the other button will automatically display the invalid symbol, you must click the "□" button to stop the operation.

8. The instrument has an emergency stop button, which is located on the right side of the front of the instrument. It needs to be released and popped up before the instrument can run.

Precautions

1. Clean and maintain the instrument in time after use.

2. If the coated substrate is smaller than the small hole range of the vacuum coating table, the exposed small hole can be covered with an electrostatic preservative film.

3. The vacuum coating table panel can be removed for cleaning. Be careful not to bump the upper and lower planes to affect the vacuuming effect.

4. The wire rod push frame can be installed in front and back (fixed by the screw of the counterweight), one side is used for wire rods with a diameter of less than 12, and the other side is used for wire rods with a diameter of more than 12. Please remove it from the push rod when not in use.

5. Specifications of vulnerable parts: O-ring seal for vacuum coating table 335×5.30 GB3452.1; O-ring seal for wire rod push frame 100×3.55 GB3452.1.

AFA-V (Vacuum)

AFA-V (Vacuum)