Pushen PS 2658 Pull-out adhesion Tester

SE-

TRUIT TR 5020 Adhesion Tester film adhesion test 20mm$ 1136.00SE

TRUIT TR 5020 Adhesion Tester film adhesion test 20mm$ 1136.00SE -

TIANDIXINGHUO XH-M Adhesion Tester Pull-off adhesion Detector 20mm$ 1424.00SE

TIANDIXINGHUO XH-M Adhesion Tester Pull-off adhesion Detector 20mm$ 1424.00SE -

KOSON KS-M coating adhesion Detector 20mm$ 917.00SE

KOSON KS-M coating adhesion Detector 20mm$ 917.00SE -

RUNJIE RJTC-10 coating Adhesion Tester$ 809.00SE

RUNJIE RJTC-10 coating Adhesion Tester$ 809.00SE -

Defelsko PosiTest AT-M 20mm pull-out adhesion instrument, manual 20mm kit size$ 3086.00SE

Defelsko PosiTest AT-M 20mm pull-out adhesion instrument, manual 20mm kit size$ 3086.00SE

Pushen PS 2658 Drawing adhesion instrumentSPEC

Pushen PS 2658 Drawing adhesion instrumentDetails

Pushen PS 2658 Drawing adhesion instrumentPacking list

- SKU

- NB027427

- Measurement mode

- manual

- Kit diameter

- 20mm

- Range

- 0.7~20Mpa/100~3000psi

- Resolution

- 0.01MPa(1psi)

- Accuracy

- ±1%F.S

- typical application

- Metallic coatings

- Display

- LCD display

- Force unit

- psi/Mpa

- Power

- Rechargeable lithium battery

- meet the standard

- GB/T 5210 ISO4624,16276-1 ASTM D4541,D7234

The pull-out adhesion Tester is a portable adhesion Tester that uses the hydraulic pull-out force of the adhesion Tester to peel off the coating from the coated substrate per unit area.

It is used in laboratories and workshops, with a single measurement range of 0-3000p in Ps and MPa through the LCD

Strong adhesion, waterproof and dustproof, and a good hose with a length of 15 meters can be used to measure relatively narrow areas

main performance

Portable design, built-in rechargeable lithium battery, no external power supply, suitable for field and laboratory use

Standard Micro-USB interface, after connecting with the computer, the instrument is similar to a U disk, which can directly copy the stored experimental data without installing any software, and is easy to use;

The machine has a built-in real-time clock, and all saved data has a corresponding experimental date and time; it is convenient for users to summarize and manage experimental data;

For products with different bonding strengths, the pull-off spindle sizes are 10, 14, 20 and 50mm, which expands the functionality and resolution of the instrument

Each instrument is factory calibrated with NIST traceable pressure transducers to an accuracy of ±1% of full scale

Internal storage of pull-off data, including maximum pull-off force, pull-off rate, test time and pull-off spindle size

The pull-off rate display makes it easier for the operator to observe and adjust the pull-off rate, in line with international standard test methods

Select pull-off unit size, change units of measure or store readings at the touch of a button

No need for conversion tables, the instrument automatically calculates the pull-off force according to the size of the pull-off unit

The pull-off unit uses inexpensive and high-quality aluminum spindles that meet international standards

The aluminum self-centering pull-off unit ensures that the pull-off force acts on the test surface evenly when testing on smooth or uneven surfaces, preventing single-sided pull-off.

High-grade industrial pressure sensors ensure continuity of accuracy

LCD display, with two units of MPa or psi

Standards

GB/T5210

lSO4624, 16276-1

ASTMD4541, D7234

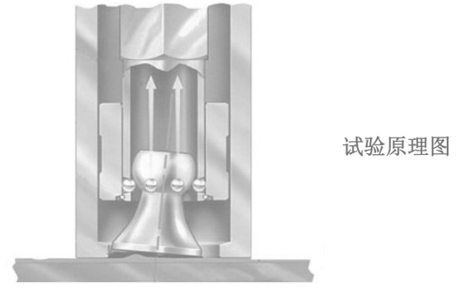

Principle

The test sample or system is applied in a uniform thickness to a flat plate with a uniform surface structure. After the coating system has dried/cured, the test post is bonded directly to the coated surface with a special adhesive. After the adhesive is cured, put the bonded test combination on the PS2658 digital display pull-off adhesion Tester. The Tester pulls the test column from the coating uniformly and at a speed not exceeding 1MPa/s through the hydraulic pump. The required force is directly displayed through the LCD of the instrument, so as to test the force required to break the adhesion between the coating/substrate.

It is worth noting that the test results are expressed by the tensile force between the failure interfaces (adhesive failure) or the tensile force of self-destruction (cohesive failure), and the adhesion/cohesive failure may occur simultaneously.

- 1SH/T 3022-2019《Design standard for anticorrosion coating of equipment and piping in petrochemical industry》

- 2ISO 2819-2017《Metallic coatings on metallic substrates - Electrodeposited and chemically deposited coatings - Review of methods available for testing adhesion (Third Edition)》

- 3ASTM D7234-2012《Standard Test Method for Pull-Off Adhesion Strength of Coatings on Concrete Using Portable Pull-Off Adhesion Testers》

- 4GB/T 39289-2020《Determination of the adhesion strength—Plastic and metal》

- 5HG/T 2454-2014《Solvent-thinned polyurethane coatings (two-component)》

- 6TB/T 2965-2011《Technical specification for waterproof layer of railway concrete bridge》

- 7ASTM B571-2023《Standard Practice for Qualitative Adhesion Testing of Metallic Coatings》

- 8ISO 9717-2017《Metallic and other inorganic coatings — Phosphate conversion coating of metals》

- 9ISO 4624-2016《Paints and varnishes -1 Pull -off test for adhesion》

- 10GB/T 6748-2008《Anticorrosive paint for ship》

PS 2658

PS 2658