LANDTEK CM8828 Film Thickness Gauge for automotive coatings

SE-

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 256.00SE

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm$ 256.00SE -

AMITTARI AC-110A built-in thickness probe with resolution of 0.1 μm$ 344.00SE

AMITTARI AC-110A built-in thickness probe with resolution of 0.1 μm$ 344.00SE -

Statistical Coating Thickness Gauge AMITTARI AC-110B Integrated Sensors can store 99 sets of thickness measurement data$ 510.00SE

Statistical Coating Thickness Gauge AMITTARI AC-110B Integrated Sensors can store 99 sets of thickness measurement data$ 510.00SE -

LANDTEK CM8825Fn platings Thickness Measurement Instrument Dual function coating Thickness Measurement Instrument$ 389.00SE

LANDTEK CM8825Fn platings Thickness Measurement Instrument Dual function coating Thickness Measurement Instrument$ 389.00SE -

LANDTEK CM8855 coating Film Thickness Gauge Integrated F magnetic Induction /NF eddy current statistical function$ 493.00SE

LANDTEK CM8855 coating Film Thickness Gauge Integrated F magnetic Induction /NF eddy current statistical function$ 493.00SE

LANDTEK CM8828 Coating Thickness GaugeSPEC

LANDTEK CM8828 Coating Thickness GaugeDetails

LANDTEK CM8828 Coating Thickness GaugePacking list

- SKU

- NB000277

- Measurement principle

- Magnetic induction + eddy current

- Measuring range

- 0 ~ 1250µm

- margin of error

- ±3%

- resolution

- 0.1mm | 1mm

- Minimum radius of curvature

- F: convex 1.5mm/concave 25mm; N: convex 3mm/concave 50mm

- thinnest matrix

- 0.3mm

- probe

- F and NF split probes

- icon function

- without

- Power

- 4 * AAA battery

- Calibrated Certificate

- without

- Language

- Chinese

- Display screen

- LCD

- supporting software

- without

- Total Weight

- 81G (without battery)

- Complete-built unit size

- 126*65*27mm

- Minimum measurement surface

- F6mm

- Unit display

- μm/mils

- Voltage prompt

- Low Voltage prompt

- Operating Temperature

- 0~40℃

- Relative Humidity

- 10~90%RH

Introduction

LANDTEK CM8828 Paint Film Thickness Gauge is a portable measuring instrument that can quickly, without damage, and accurately measure the thickness of automotive coatings and coatings; .

Applications

Paint Film Thickness Gauge CM-8828 uses a magnetic sensor to measure non-ferromagnetic coatings and coatings on ferromagnetic metal substrates such as steel and iron, such as: paint, powder, plastic, rubber, synthetic materials, phosphating, chromium , zinc, lead, aluminum, tin, cadmium, porcelain, enamel, oxide layer, etc. Use eddy current sensors to measure enamel, rubber, paint, plastic layers, etc. on copper, aluminum, zinc, tin, etc. substrates. Widely used in manufacturing, metal processing, chemical industry, commodity inspection and other testing fields.

Features

The paint Film Thickness Gauge CM-8828 can measure the thickness of the non-magnetic coating on the magnetic conductive object and the non-conductive coating on the non-magnetic metal substrate.

Pictures

Features and advantages

* Iron-based and non-ferrous-based dual-purpose paint Film Thickness Gauge.

* The domestic (CN) dual-purpose coating Thickness Gauge has two optional measurement methods: single and continuous.

* Metric/Imperial unit conversion.

* It has functions such as manual shutdown, automatic shutdown and underVoltage reminder.

* Automatically memorize the calibration value and automatically identify the material of the measured substrate.

* The domestic (CN) dual-purpose paint Film Thickness Gauge has a buzzer sound during operation, but the buzzer does not sound during continuous measurement.

* The domestic (CN) dual-purpose paint Film Thickness Gauge adopts USB data line output, RS-232C data connection line and software to communicate with PC.

* Optional Bluetooth™ data output option is also available.

* Paint Film Thickness Gauge, one-button operation, fast and convenient.

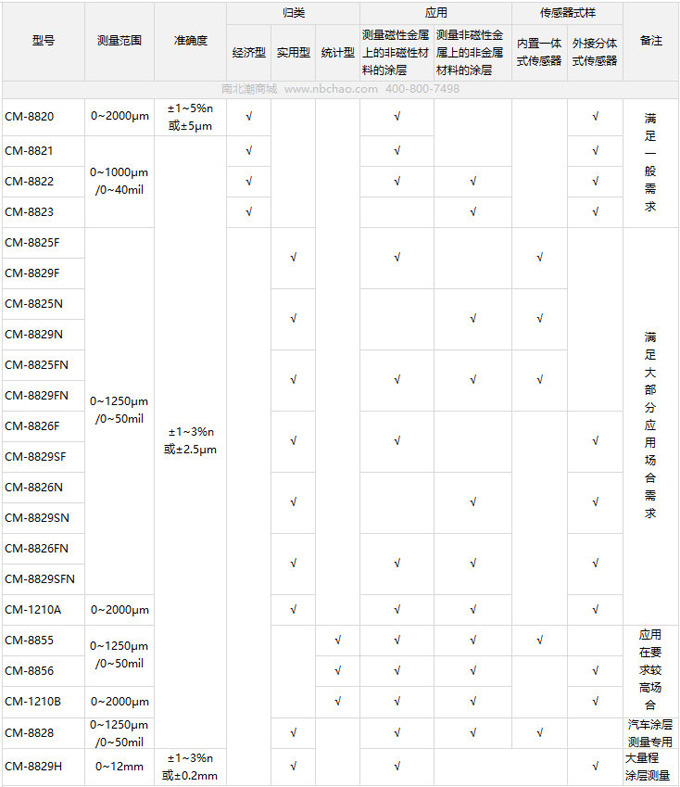

LANDTEK Coating Thickness Gauge Selection List

- 1QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 2JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 3GB/T 1727-2021《General methods for preparation of coating films》

- 4HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 5HG/T 5367.1-2018《Coatings for rail transit vehicles - Part 1: Waterborne coatings》

- 6ASTM B244-2021《Standard Test Method for Measurement of Thickness of Anodic Coatings on Aluminum and of Other Nonconductive Coatings on Nonmagnetic Basis Metals with Eddy-Current Instruments》

- 7ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 8 B530-2014《》

- 9ISO 2360-2017《Non-conductive coatings on non-magnetic electrically conductive base metals — Measurement of coating thickness — Amplitude-sensitive eddy-current method》

- 10ISO 2178-2016《Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method》

CM8828

CM8828