MITECH mitech CDX-A Magnetic Particle Flaw Detector

mitech CDX-A Magnetic Particle Flaw DetectorSPEC

mitech CDX-A Magnetic Particle Flaw DetectorDetails

mitech CDX-A Magnetic Particle Flaw DetectorPacking list

- SKU

- NB028061

- Operating Voltage

- AC 220V

- Operating current

- 5A

- output Voltage

- AC 38V

- output current

- 12A

- Dimension

- 130*265*200mm

- Host Weight

- 7.0Kg

- Battery yoke size

- 110*240*45mm

- Battery yoke distance

- 20-160mm

- Battery yoke Weight

- 1.8Kg

- lifting force

- ≥ 45N (lifting force not less than 5kg)

- Flaw detection speed

- ≥ 6 meters/min

- Probe temperature rise

- ≤60℃

- Comprehensive Sensitivity

- A-type 30/100 standard test piece manual grooving display is clear

- Communication storage

- none

- relevant standards

- JB/T8290-1998

Mattel's CJX-A multifunction magnetic particle flaw Detector is based on the principle of magnetic interaction between the leakage magnetic field and the magnetic particle to accurately and intuitively show the shape of the defectShape, location, size, and severity to determine the nature of the defect. The instrument can be equipped with three kinds of probes: A, D and O, which can realize magnetic clamp flaw detection and electromagneticYoke flaw detection, cross yoke flaw detection, ring flaw detection four flaw detection functions, using a variety of magnetization methods, can detect all parts of the workpiece, is widely transportedIt is used for defect detection in petroleum, chemical industry, metallurgy, shipbuilding, aviation, railway and other fields, and is required for quality control, in-service safety monitoring and life assessmentProfessional precision instruments.

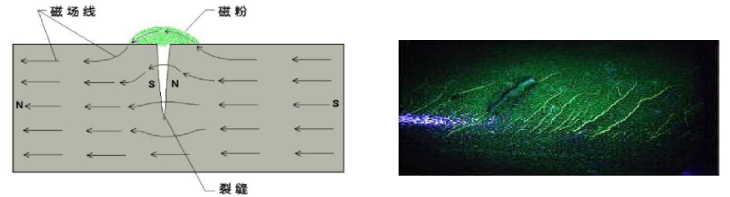

Operating Principle

The object of the ferromagnetic material to be tested is magnetized by placing it in a strong magnetic field or by applying a strong electric current if there is a defect on or near the surface of the object(cracks, folds, inclusions, etc.), magnetic field lines will produce magnetic flux leakage near these defects, and when magnetic particles with good permeability (usually magneticIron oxide powder) when applied to an object, the leakage magnetic field near the defect will attract the magnetic particle, accumulating to form visible traces of magnetic particle, in the right lightVisible magnetic marks are formed under illumination, which show the position, size, shape, and severity of continuity, revealing the defect.

Application

Mattel's CJX-A multi-function magnetic particle flaw Detector is widely used in electric power, oil field, coal mine, chemical industry, railway, automobile, steel structure equipment, etcindustrial products; Specific workpiece types include chain rods, crankshafts, bearings, high-strength bolts, springs, forgings, petrochemical pipe fittings, valves, blades, gears,Workpieces with complex geometries such as anchor chains and welds.

Features

The application of the new power mode has improved the depth of defect detection and the sensitivity performance of surface inspection.

Adjustable yoke spacing to enhance the practicability of the instrument;

It has the function of powering on and lighting, which is convenient for use in poor light conditions;

Equipped with three different optional magnetic probe devices, it enhances the adaptability and accuracy of the measurement of different shapes of workpieces;

Using a variety of magnetization methods, it is almost not limited by the size and geometry of the part, and can pick up and measure all parts of the workpiece;

The ergonomic design and thyristor are used as the magnetization switch, which is convenient for the Detector to control the magnetization switch at any time when holding the probe;

The inspection and flaw detection speed is fast, the process is simple, and the cost is low;

Detection of defects under the surface of the workpiece from 0.5 to 3 mm, and for larger pores, up to 5 mm with DC magnetization;

With extremely high detection sensitivity, magnetic marks formed by magnetic particles accumulating on defects have a magnifying effect and can be detected with a minimum width of 0.1Micron.

CDX-A

CDX-A