Mitech MT-1B Portable Magnetic Particle Flaw Detector

mitech MT-1B Magnetic Particle Flaw DetectorSPEC

mitech MT-1B Magnetic Particle Flaw DetectorDetails

mitech MT-1B Magnetic Particle Flaw DetectorPacking list

- SKU

- NB028062

- lifting force

- ≥ 45N (lifting force not less than 5kg)

- Comprehensive Sensitivity

- A-type 15/100 standard test piece manual grooving display is clear

- Lighting device

- White light illumination

- Operating Voltage

- DC 15V-21V

- The output waveform of the instrument

- communicate

- Instrument output pulse amplitude

- 42V

- Dimensions of the host

- 100mm×204mm×36mm

- Host Weight

- 0.75Kg (including battery pack)

- Display

- 3.2 inches

- Electromagnetic yoke size

- 174mm×162mm×38mm

- electromagnetic yoke pole distance

- 75-200mm

- Electromagnetic yoke Weight

- 1.5kg

- Nominal Voltage of lithium battery pack

- 18V

- Rated Capacity of lithium battery pack

- 8400mAh

- Lithium battery pack charging limit Voltage

- 21V

- Power Supply

- 220V 50HZ

- Charging time

- 3-4h

- Working time

- >4h

The Mattel MT-1B Portable Magnetic Particle Flaw Detector is powered by a high-capacity lithium battery pack that converts the DC power provided by the rechargeable battery through a frequency conversion inverterVariable and signal phase shift processing provides magnetized power supply for the magnetic particle flaw Detector, which solves the disadvantages of the traditional magnetic particle flaw Detector relying on 220V power supply, and has low power consumption.It can work continuously for more than 4 hours on a single charge, and the battery can be charged online or offline. It is especially suitable for on-site flaw detection and field without power supply in the fieldAerial.

Features

The large-capacity lithium battery pack is powered and can be carried to the site at will, which solves the disadvantages of the traditional magnetic particle flaw Detector relying on 220V power supply, with low power consumption and small size, and the battery can be charged online or offline. It is especially suitable for field and high-altitude flaw detection;

Mattel series portable magnetic particle flaw Detectors have adjustable lighting brightness and adjustable power to meet the needs of flaw detection in different environments, and the setting status can be carried outStorage;

The application of the new power mode enables this product to achieve both the depth of the detection defect and the sensitivity performance of the surface inspectionHoist;

The electromagnetic yoke adopts pulsating power supply technology, which can work continuously and uninterruptedly, and is not limited by the gap time required by the traditional electromagnetic yoke;

It combines all the advantages of traditional magnetic particle flaw Detectors to detect near-surface defects quickly, clearly and accurately;

Lighting brightness, power, yoke spacing can be adjusted to meet the needs of different measurement conditions;

This product is portable and compact, equipped with an instrument bag, and the operator can straddle the instrument diagonally around the waist, which greatly reduces the labor intensity of the flaw Detector personnelHigh productivity.

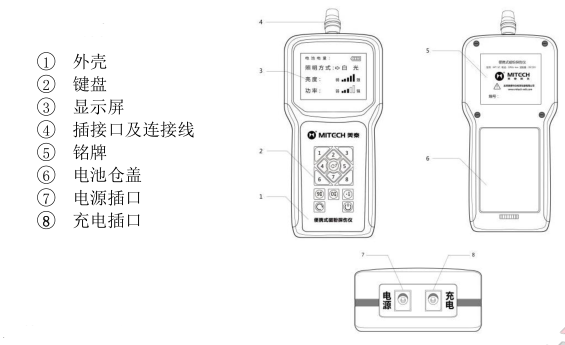

Appearance of the instrument

MT-1B

MT-1B