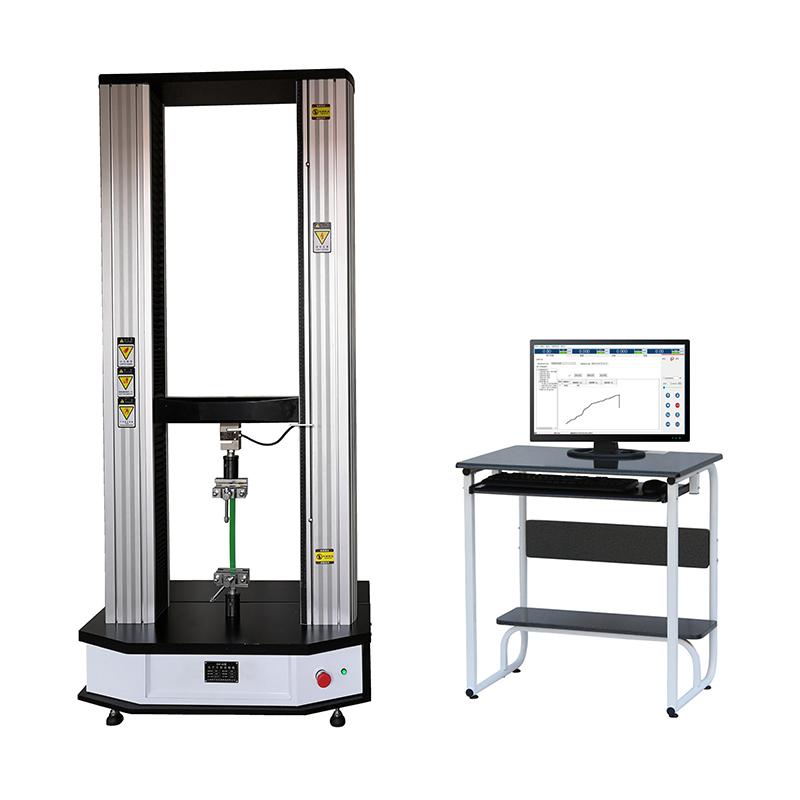

Rongjida WDW-5KN electronic universal Tester, the test force reaches 5KN

RongJiDa WDW-5KN Electronic universal testing machineSPEC

RongJiDa WDW-5KN Electronic universal testing machineDetails

RongJiDa WDW-5KN Electronic universal testing machinePacking list

- SKU

- NB028139

- Maximum test force

- 5KN

- High Precision Sensors Precision

- ±0.5%

- Load Accuracy

- ± 1% resolution 1/20000 yards

- Speed Accuracy

- ±0.5%

- Test speed range

- 0.05~ 500mm/min (above 1T: 1~ 250mm/min) or set according to user requirements

- displacement resolution

- 0.1mm

- Large Measurement range

- Marking line - 1000mm (optional)

- Effective travel of moving beam

- 1000mm can make different stretching spaces according to user requirements

- Displacement error of indication

- ±0.5%

- Power

- AC220V 50Hz

- Dimensions

- 700*380*2150mm

- Net Weight

- 320K

Introduction

Waterproof membrane Tensile Testing Machine is widely used in mechanical analysis and testing of polymer materials, waterproof membranes, mortar building materials, plastic rubber, wires, cables, textiles, engineering plastics, ceramics, metal materials, food and pharmaceutical packaging and other industries. The waterproof membrane Tensile Testing Machine is equipped with special fixtures, which can be used for stretching, compression, bending, shearing, peeling, tearing, etc. A number of physical and mechanical performance tests. Equipped with branded computers, Chinese WINDOWS XP user interface, menu prompts, mouse selection operations, data and curves are dynamically displayed along with the test process. easy and convenient.

Software performance and characteristics of waterproof membrane Tensile Testing Machine

1. Equipped with brand computer, Chinese WINDOWS XP user interface, menu prompt, mouse selection operation, simple and convenient.

2. Display mode: data and curves are dynamically displayed along with the test process.

3. Automatic shifting: automatically switch to the appropriate range according to the load to ensure the accuracy of the measurement data.

4. Control process: the test process and functions such as measurement, display, analysis, and printing are all completed by the computer

5. Curve method: stretching: force-elongation, stress-strain, strength-time; force-time, elongation-time, strain-time. compression:

Force-Deflection, Stress-Strain, Strength-Time, Force-Time, Deformation-Time, Strain-Time Bending Resistance: Force-Deflection, Strength-Time, Force-Time, Deflection-Time.

6. Curve comparison: the curves of the same group of tests can be superimposed and compared in multiple colors.

7. Partial magnification test: Any segment on the curve can be magnified and analyzed.

8. Data analysis: The test data on the graph can be selected and analyzed at will.

9. Report selection: different report formats can be selected according to user needs, and EXCEL or Word can be used. View the report directly or take a partial print

10. Sample selection: effective test can be selected for a group of sample results, and can be tested continuously

11. Automatic storage: test conditions, test results, test curves and data can be automatically stored and recalled at any time.

12. Stop at break: the sample can stop or return to the initial position when the sample is broken.

13. Automatic protection: automatic overload, overcurrent, overVoltage, underVoltage, upper and lower limit protection.

14. Automatic return: different speeds can be set for the moving beam, and it can accurately and automatically return to the initial position of the test.

15. Control function: with constant speed control mode.

16. Different force value units can be selected (N, kgf, gf)

17. Printing: It can process, store, print and draw curves for the test data, and print the report card, which can also be printed collectively or separately.

18. Automatic calibration: The load and elongation can be automatically calibrated with electrical calibration values.

19. Zero reset: Manual or automatic zero reset can be performed at any time for load, deformation and displacement measurement.

Operating Conditions of waterproof membrane Tensile Testing Machine

1. The ambient temperature is between 10-30°C

2. Relative Humidity ≤80%

3. Install correctly on a solid foundation or workbench

4. There is no vibration source and corrosive substances around

5. The fluctuation range of the power supply Voltage should not exceed ±5% of the rated Voltage

Structural characteristics and Principle of waterproof membrane Tensile Testing Machine

This machine is mainly composed of mechanical and electrical components.

1. The structure and Principle of the mechanical part

Mechanical loading is adopted, the reducer is driven by a motor, and the power transmission screw drives the middle beam to move up and down. Two fixtures are installed on the middle beam and under the upper beam to realize the tensile and compression tests on the specimen.

2. The characteristics and Principle of the measuring part

It adopts computer control, high-precision load cell, high-precision AD conversion and imported photoelectric encoder, which has the characteristics of intuitive display, convenient operation and accurate data. Provide on-site calibration and peak hold functions.

The Principle is as follows: Loading the testing machine causes the sensor to generate an electrical signal and send it to the AD converter. At the same time, the screw rotates to drive the encoder to generate a pulse signal and input it to the microcomputer. After the control adjustment, the test result is displayed on the microcomputer screen.

- 1Differences between imported and domestic (CN) Abrasion Tester

- 2Modern environment WDW-20 microcomputer controlled electronic universal testing machine operation instructions

- 35 Things You Need to Know Before Buying a Tensile Test Fixture

- 4Tensile machine test specimen 60/hour

- 5Detection Error Analysis of Force Lever calibrated Tensile machine

- 6Cupping test of sheet metal forming limit diagram

李伟锋;乔明杰 - 《锻压技术》

- 7Modern environment electronic universal testing machine operating instructions

- 8Tensile test of mechanical performance of stainless steel pipe

- 9Effect of scratch agent on performance of polycarbonate/whisker silicon system

孙小文; 刘斌; 邱谍 - 《中国塑料》

- 10Analysis of gas turbine coating cupping performance

冯文;李正超;向旭东 - 《东方汽轮机》

- 1 10302-2023《Sag resistance polyurethane waterproofing coating》

- 2 10310-2023《Waterborne polyurethane waterproof coating》

- 3GB/T 16826-2023《Electro-hydraulic servo universal testing machines》

- 4GB/T 22378-2008《Pressure sensitive adhesives tapes of BOPP for general purpose》

- 5JG/T 158-2013《Products for external thermal insulation systems based on mineral binder and expanded polystyrene granule plaster》

- 6HG/T 5776-2020《Water-based coatings for surface of rubber sealing products》

- 7HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 8GB/T 19250-2013《Polyurethane waterproofing coating》

- 9GB/T 4074.10-1983《Enameled wire test method, film adhesion test----flat wire》

- 10JC 500-1992《Polyurethane waterproof coatings》

WDW-5KN

WDW-5KN