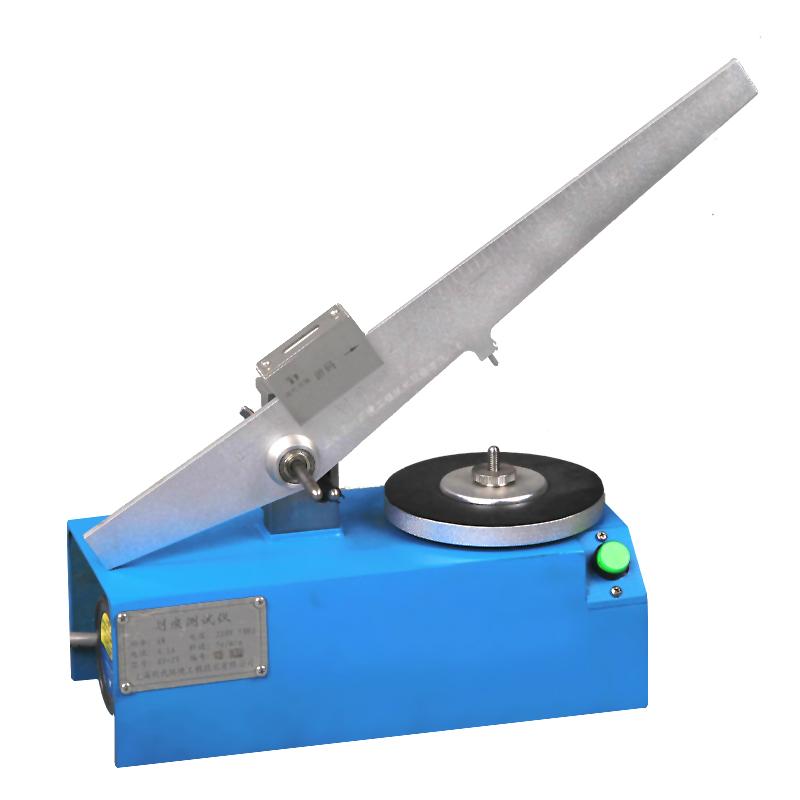

MODERNER HY-V Scratching Tester

SEModerner HY-V Scratching TesterSPEC

Moderner HY-V Scratching TesterDetails

Moderner HY-V Scratching TesterPacking list

- SKU

- NB028400

- Motor power

- 6W

- Turntable speed

- 5±1rpm

- Maximum size of test sample

- 100*100mm

- Load (loading) range

- 0~10N

- Power

- 220V AC 50Hz

- Overall Dimensions

- 430*230*200mm

- Weight

- 4.5kg

- Test sample maximum Film thickness

- 20mm

HI-V scratch Tester is suitable for testing the surface scratch resistance of various wood-based panels and decorative wood-based panels. The instrument adopts a gear reducer with a large speed ratio and a large output torque to ensure a constant rotation speed of the turntable under different test loads, so that the test results have high accuracy. All the parts of the scratch Tester are installed in a wooden box with a handle, which has the characteristics of compact structure, small appearance and easy to carry.

Standards

GB/T15102, GB/T17657, GB/T18102

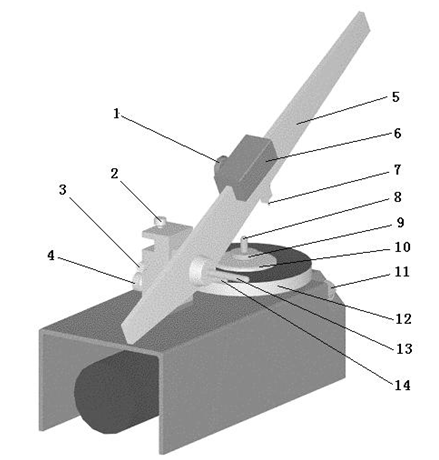

product structure

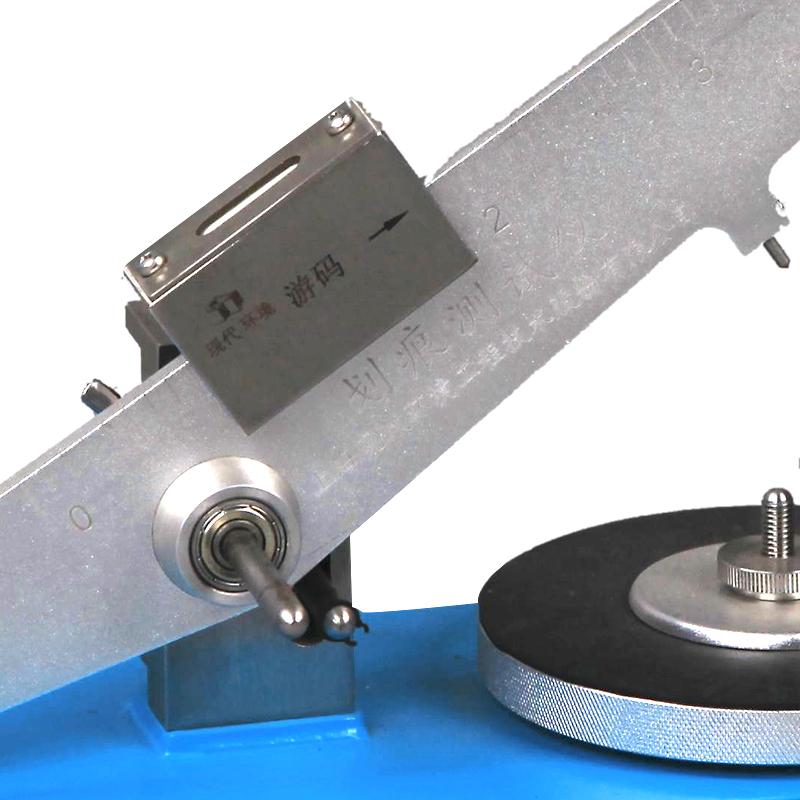

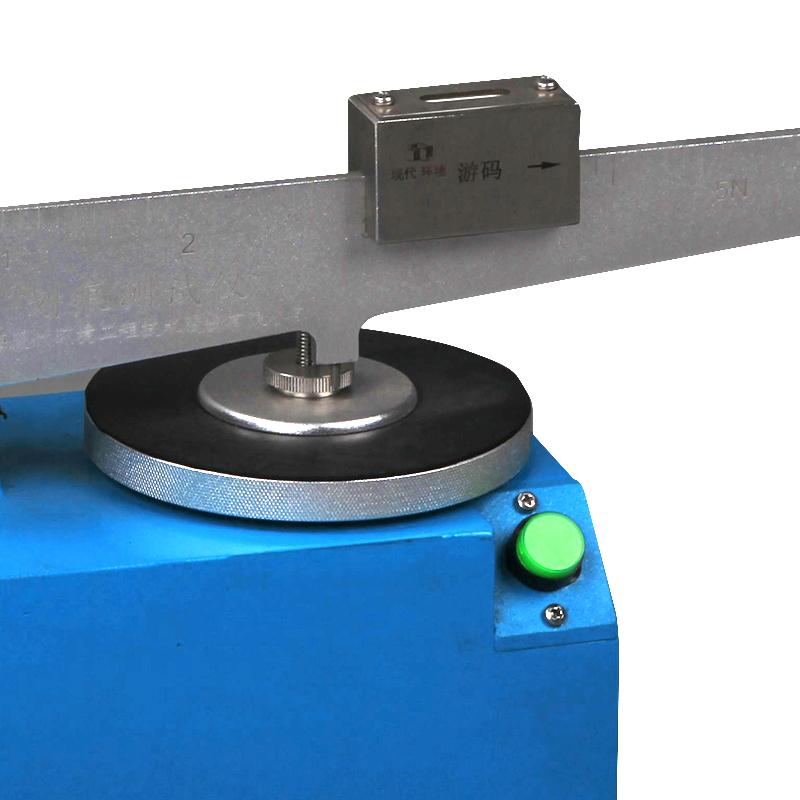

The scratch Tester uses the principle of leverage. When the upper edge of the scale is in the horizontal position, move the weight above the scale to different scale values, so that the force of the tip of the diamond stylus on the surface of the plate to be tested can match the scale value. The rotating shaft of the scale is supported by ball bearings, which can rotate flexibly and reduce the frictional moment, so that the pressure applied to the tip of the diamond stylus has good repeatability, that is to say, the test results have good repeatability.

1. Weight screw 2, scale adjustment screw 3, slider fixing screw 4, scale bracket screw 5, scale 6, weight 7, diamond marking needle 8, center screw 9, specimen fixing nut 10, specimen pressure plate 11, Start button 12, specimen turntable 13, scale slider 14, scale support rod

- 1ISO FDIS 1518-2010《Paints and varnishes. Scratch test》

- 2 1518-2010《Paints and varnishes. Scratch test》

- 3ISO 1518-1-2023《Paints And Varnishes - Determination Of Scratch Resistance - Part 1: Constant-Loading Method》

- 4ISO 12137-2011《Paints and varnishes Determination of mar resistance》

- 5SY/T 4113-2007《Pipeline coating test method.Part 1 : Gouge resistance test》

- 6GB/T 17657-2013《Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels》

- 7GB/T 15102-2017《Surface decorated fiberboard and particleboard with paper impregnated thermosetting resins》

- 8GB/T 18102-2007《Laminate flooring》

- 9ISO 12137-2-1997《Paints and varnishes - Determination of scratch resistance - Part 2: Method of scribing with tip》

- 10ISO 12137-1-1997《Paints and varnishes - Determination of scratch resistance - Part 1: Method for curved strokes and 1998 Technical Amendment 1》

HY-V

HY-V