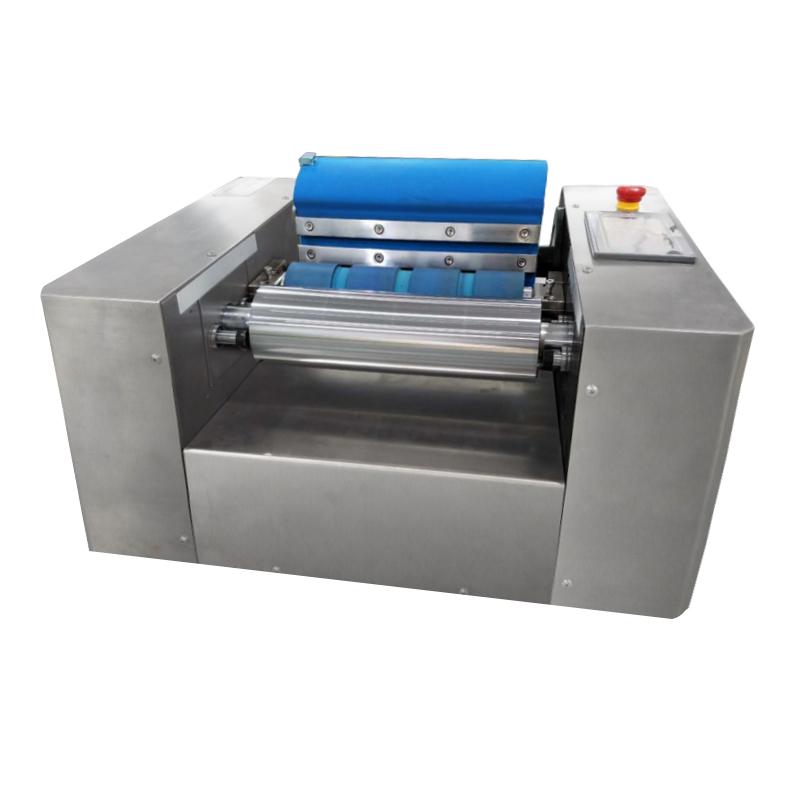

JINGHUAYIQI LD-JDY offset plate Ink Proofer printing adaptor

SE-

PUYUN PY-E626 offset plate inks spot color Proofer (four colors)$ 3360.00SE

PUYUN PY-E626 offset plate inks spot color Proofer (four colors)$ 3360.00SE -

YOUKE YK2205 four color offset plate ink color matching instrument printing Proofer$ 3548.00SE

YOUKE YK2205 four color offset plate ink color matching instrument printing Proofer$ 3548.00SE -

IMT-IGT309A offset plate inks Spot Color Proofer (Separate) Printability Tester

IMT-IGT309A offset plate inks Spot Color Proofer (Separate) Printability Tester -

IMT-310A Offset Printing ink Spot Color Proofing Machine (Fixed)

IMT-310A Offset Printing ink Spot Color Proofing Machine (Fixed)

JingHuaYiQi LD-JDY Offset plate Ink ProoferSPEC

JingHuaYiQi LD-JDY Offset plate Ink ProoferDetails

JingHuaYiQi LD-JDY Offset plate Ink ProoferPacking list

- SKU

- NB028463

- Total power consumption

- 350W

- Power

- AC220V 50Hz

- Dimensions

- 555*440*320mm

- Weight

- About 90KG

- Proofing effective area

- 40 * 220mm (4 pieces) 60 * 220mm (3) 100 * 220mm (2 pieces), optional exhibition material size: 290 * 250 mm

- Proofing speed

- 400、550、700rpm

- Proofing speed

- 0~1000rpm

- Proofing speed

- 10/15/20rpm

- Color development speed variable frequency speed regulation

- 0-30 rpm

- Ink leveling time

- 1~ 800S adjustable

Introduction

The fully automatic color development machine can print color bars of different colors at the same time or print the same ink color bars with different ink layer thicknesses. It can also print new and old inks for comparison on the same printing material, providing effective color contrast.

Features

1. Spot color proofing

The multi-stage color development instrument can print color bars of different colors at the same time or print the same ink color bars with different ink layer thicknesses. It can also print new and old inks for comparison on the same printing material, providing effective color contrast.

Two, four-color ink detection

It can detect the hue, gloss, and color density of the ink; start with controlling the quality of ink raw materials, so as to achieve the purpose of controlling the quality of printed products.

3. For customer prepress spot color approval

Simple color bars can be produced for customer pre-press approval or archiving.

4. Detect the degree of discoloration of dry and wet ink

The color display machine displays the required spot color ink strips, and after natural drying, the hue of the spot color after drying can be known. (For example: the phenomenon that purple and dark blue will turn red after drying can be ruled out before printing.)

5. When used with the ink quantifier , the usage of spot color ink can be predicted, and the loss of residual ink and storage accumulation can be greatly reduced.

6. Data Management

Cooperate with the spectrodensitometer for color detection, and can measure the data report (Lab value) of the color bar.

7. Cooperating with related instruments, the characteristics of ink abrasion resistance, fading, transferability, light resistance and heat resistance can be predicted.

ink distribution mode

1. The ink distribution speed can be switched between automatic and manual, which is suitable for different operating habits and special conditions;

2. The serial movement can set the middle positioning without serial movement soft start mode, reduce the unevenness of color development and the phenomenon of flying ink, and improve the accuracy of color development;

3. Time setting of four stages of ink distribution mode (0-200 seconds for each segment), which can be set for any ink distribution method: positioning in series, intermittent closing, fixed closing and automatic speed change, more accurate and humanized ;

4. Ink distribution pressure (automatic): It can be automatically adjusted according to the wear condition of the rubber roller or the error of the old and new rubber rollers.

5. Color development pressure (automatic): Automatic adjustment according to the thickness of color development material (-1~+1 mm), more accurate and convenient.

6. Cleaning: In the cleaning mode, the metal roller does not move in series, which is safe and convenient.

7. Cots: standard common and UV dual-purpose rollers.

- 1GB/T 17001.3-2025《Anti-counterfeiting printing ink—Part 3:Thermochromic anti-counterfeiting printing ink》

- 2GB/T 13217.5-2023《Inks drying inspection method》

- 3ISO 2846-1-2017《Graphic technology - Colour and transparency of printing ink sets for four-colour printing - Part 1: Sheet-fed and heat-set web offset lithographic printing》

- 4GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6GB/T 22365-2008《Paper and board - Determination of printing surface strength - Accelerating speed method》

LD-JDY

LD-JDY