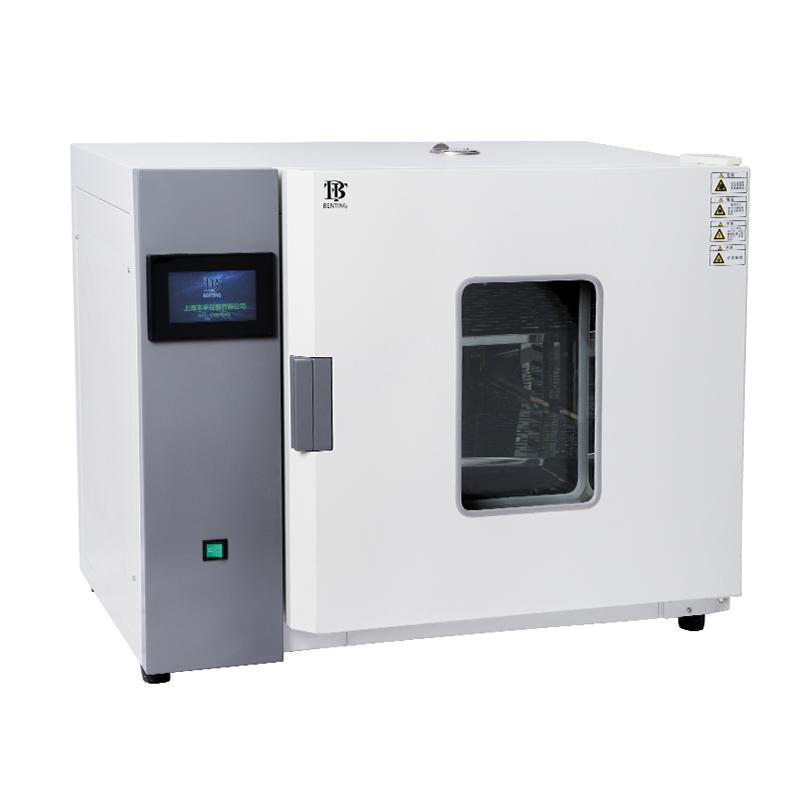

BENTING CBGLL-230BE vertical intelligent Forced Air Drying Oven 300 ℃/225L

SE-

CHINA DHG-9240B vertical Forced Air Drying Oven experiment electric heating cycle oven 300 ℃/225L$ 640.00SE

CHINA DHG-9240B vertical Forced Air Drying Oven experiment electric heating cycle oven 300 ℃/225L$ 640.00SE -

BENTING CBGL-230B vertical standard Forced Air Drying Oven 300 ℃/225L oven

BENTING CBGL-230B vertical standard Forced Air Drying Oven 300 ℃/225L oven -

SANFA DHG-9101-3A Electrothermal thermostatic Drying Oven 225L/stainless steel$ 717.00SE

SANFA DHG-9101-3A Electrothermal thermostatic Drying Oven 225L/stainless steel$ 717.00SE -

BOZHEN DGG-9246A Vertical Forced Air Drying Oven 225L/300 ℃$ 770.00SE

BOZHEN DGG-9246A Vertical Forced Air Drying Oven 225L/300 ℃$ 770.00SE

BenTing CBGLL-230BE Forced Air Drying OvenSPEC

BenTing CBGLL-230BE Forced Air Drying OvenDetails

BenTing CBGLL-230BE Forced Air Drying OvenPacking list

- SKU

- NB028558

- Temperature range

- RT+10~300°C

- Temperature fluctuation

- ±1.0℃

- Temperature Resolution

- 0.1℃

- Volume

- 225L

- Interior size

- 600*500*750mm

- Inner chamber material

- stainless steel

- Shelf (std.)

- 2pcs

- Maximum total load

- 25/kg

- Timer

- 1~9999min

- Power

- 220V/50HZ

- Heating power

- 3kw

- Environment temperature

- +5-40℃

- Dimensions

- 730*670*1220mm

- Net Weight

- 70kg

- Enclosure Material

- Cold rolled steel plate

- Packing size

- 900*800*1350mm

- Gross Weight

- 105Kg

Overview

BGLL series Forced Air Drying Oven has the characteristics of excellent design, novel shape, professional technology, accurate temperature control, stable performance, easy maintenance, convenient operation, etc. It is suitable for drying, baking, For wax melting and heat treatment.

Features

1. Novel vertical design, enclosure is made of high-quality steel plate, the surface is treated by electrostatic spraying process, the appearance is beautiful, anti-corrosion and durable.

2. The four corners are in a circular arc transition, the distance between the partitions is adjustable, and the side plate of the air duct and the bottom heating cover are quick-detachable structures, which are easy to clean.

3. The unique bottom blowing and bottom heating of the turbine centrifugal fan blades are reasonably coordinated, and the vertical double air duct vertical hot air circulation design makes the temperature distribution in the working room more uniform.

4. The speed-adjustable fan can adjust the required air volume according to different experimental requirements of users, which not only ensures the temperature uniformity in the working room, but also does not blow powdery objects.

5. Large-screen LCD, multiple sets of data can be displayed on one screen, unique navigation operation keys, and the use method is more humanized. Timing and over-temperature alarm function, with parameter memory and call reply function to protect data loss due to power failure and crash state.

6. There is an independent temperature limit alarm system. When the main controller fails, it will alarm and cut off the output in time. The double protection ensures the safe operation of the experiment without accidents.

7. Optional 485 interface, can be connected to a computer, and can remotely monitor the change status of temperature parameters.

8. The door adopts a new structure with good heat insulation effect. There is a double-layer tempered glass observation window with a large Viewing Angle in the middle, equipped with a lock-type elastic adjustment door lock, and a high-temperature-resistant silicone sealing strip to ensure good sealing and prevent heat loss. .

Note: BGLL-230BE and BGLL-625BE have no fan speed regulation function; BGLL-625 is top blower.

Parameter comparison

| model | heating power | studio size | |

| BGL-30B/BGLL-30BE | 0.8 | 310×310×310 | |

| BGL-45B/BGLL-45BE | 1.2 | 350×350×350 | |

| BGL-65B/BGLL-65BE | 1.6 | 400×360×450 | |

| BGL-125B/BGLL-125BE | 2.3 | 500×450×550 | |

| BGL-230B/BGLL-230BE | 3 | 600×500×750 | |

| BGL-625B/BGLL-625BE | 5 | 660×760×1250 | |

| Unit: KW, mm | |||

| Other parameters | |||

| Temperature control range | RT+10-300℃ | ||

| Constant temperature fluctuation | ±1.0℃ | ||

| temperature resolution | 0.1°C | ||

| Working temperature | +5-40℃ | ||

| Timer Range | 1-9999min | ||

| * Performance parameter test under no-load conditions: ambient temperature 20°C, ambient humidity 50%RH | |||

- 1SL 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 2GB/T 9995-1997《Determination of moisture content and moisture regain of textile--Oven-drying method》

- 3GB/T 6102.1-2006《Test method for moisture regain in raw cotton by oven drying》

- 4GB/T 6978-2007《Test method for the determination of scoured yield of greasy wool - Drying oven method》

- 5GB/T 10514-2012《Determination of free water for nitrophosphate - Oven method》

- 6GB/T 24131.1-2018《Rubber, raw—Determination of volatile matter content—Part 1:Hot-mill method and oven method》

- 7GB/T 30648.5-2015《Paints and varnishes—Determination of resistance to liquids—Part 5: Temperature-gradient oven methods》

- 8SL/T 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 9GB/T 32710.10-2016《Safety requirements for environmental testing and conditioning equipment—Part 10: Electric gravity convection ovens and forced ventilation ovens》

- 10GB/T 30435-2013《Electric gravity convection and forced ventilation ovens》

CBGLL-230BE

CBGLL-230BE