MODERNER QXD-300 single-channe Fineness gauge 0~300μm (customized)

SEModerner QXD-300 (single-channe) Single-channe Fineness gaugeSPEC

Moderner QXD-300 (single-channe) Single-channe Fineness gaugeDetails

Moderner QXD-300 (single-channe) Single-channe Fineness gaugePacking list

- SKU

- NB029237

- Scraper type

- Single-channe

- Number of grooves

- 1

- range

- 0~300μm

- Scale unit

- μm

- Scraper size

- 170*50*12mm

- Drawdown blade size

- 70mm

- Graduation

- 10μm

- Groove size

- 12.7mm

QXD-300 Single Slot Grindometer is a stainless steel small single groove Grindometer in MODERNER, the range of QXD-300 is 0~300μm, the graduation value is 10 microns, and the number of grooves is 1.QXD-300 single-groove scraper fineness Tester is suitable for particle fineness detection in coatings, pigments, printing inks and other industries, and is a manual fineness test.

Application

Applications for the QXD Single Slot Grindometer include:Paints, plastics, pigments, printing inks, paper, ceramics, food, etc.

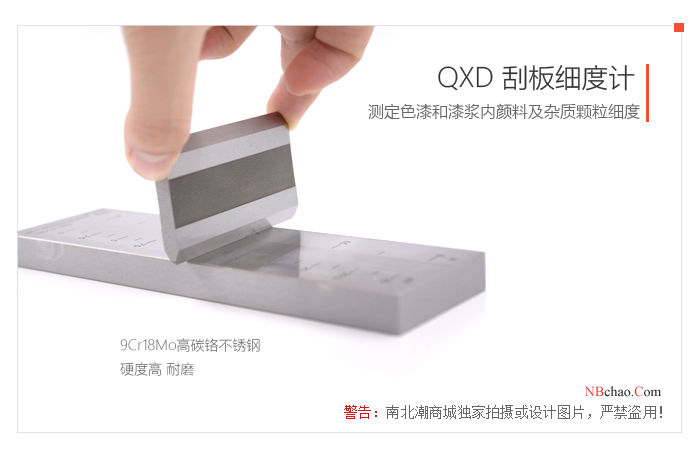

Live shot

Operating Principle:

1. In useQXD-300 Single Slot Scraper Fineness MeterWash the plate and bottom with a suitable solvent and dry it with cotton yarn.

2. The sample that meets the standard viscosity index of the product is fully stirred with an ink mixing knife.

3. InQXD Single Slot Scraper Fineness MeterIn the deepest part of the trench, drop a few drops of the sample solution.

4. Hold the scraper with the thumb, index finger and middle finger of both hands, and place it horizontally at the upper end of the stainless steel Grindometer, so that the scraper is perpendicular to the surface of the Grindometer, and pull the scraper from the deep part of the groove to the shallow part at an appropriate speed, so that the paint sample is filled with the groove and there is no excess paint left on the plate.

5. After scraping, immediately (in no more than 5 seconds) horizontal pinchingQXD Single Slot Scraper Fineness MeterAnd tilt, so that the line of sight and the groove plane are 15-20 degrees, the light to observe the particles in the trench and the scale value of the exposed place, the reading value is the fineness of the measured object.

Maintenance

(1) Immediately after use, clean and apply petroleum jelly to prevent the Fineness Meter from rusting.

(2)QXD-300 Single Slot Scraper Fineness MeterDo not scratch the surface of the scraper.

(3) When measuring the fineness, the clear oil that meets the product standard should be adjusted before useQXD Single Slot Scraper Fineness MeterMensuration.

(4) Regularly (one year) check the straightness of the knife edge and Fineness Meter, and find that the unevenness or Fineness Meter is worn, and it needs to be corrected by the national metrology verification agency before it can be used.

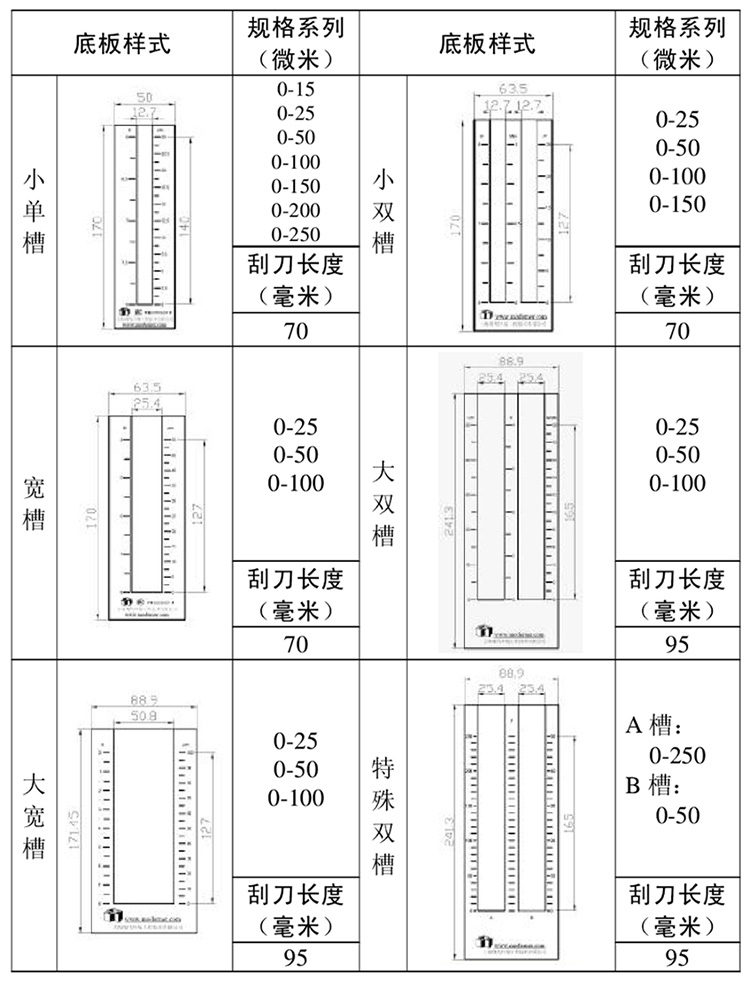

List of specifications

Series

| specification | Range | Graduation value | Groove size | unit |

| Small single slot | 0-15 | 0.75 | 12.7*140 | μm |

| 0-25 | 1.25 | Hegman/μm | ||

| 0-50 | 2.5 | |||

| 0-100 | 5 | |||

| 0-150 | 5 | μm | ||

| Small double slots | 0-25 | 2.5 | Hegman/μm | |

| 0-50 | 2.5 | |||

| 0-100 | 5 | |||

| 0-150 | 5 | μm | ||

| Wide grooves | 0-25 | 1.25 | 25.4*127 | Hegman/μm |

| 0-50 | 2.5 | |||

| 0-100 | 5 | |||

| Large wide slots | 0-25 | 2.5 | 50.8*127 | |

| 0-50 | 5 | |||

| 0-100 | 5 | |||

| Large double slots | 0-25 | 2.5 | 25.4*165 | Hegman/μm/NPIRI |

| 0-50 | 5 | |||

| 0-100 | 5 | |||

| Special double slots | 0-50 | 2 | μm | |

| 0-250 | 10 | μm |

- 1HG/T 5173-2017《Waterborne primer for application on rusty substrates》

- 2GB/T 42541-2023《Coated steel pipes for gas piping》

- 3HG/T 5175-2017《Water-based decorative coating for glass and ceramic products》

- 4ASTM D1316-2020《Standard Test Method for Fineness of Grind of Printing Inks By the NPIRI Grindometer》

- 5ASTM D333-2021《Standard Guide for Clear and Pigmented Lacquers》

- 6GB/T 13217.3-2008《Test method for fineness of grind of liquid ink》

- 7GB/T 17459-1998《Ductile cast iron pipe asphalt coating》

QXD-300 (single-channe)

QXD-300 (single-channe)