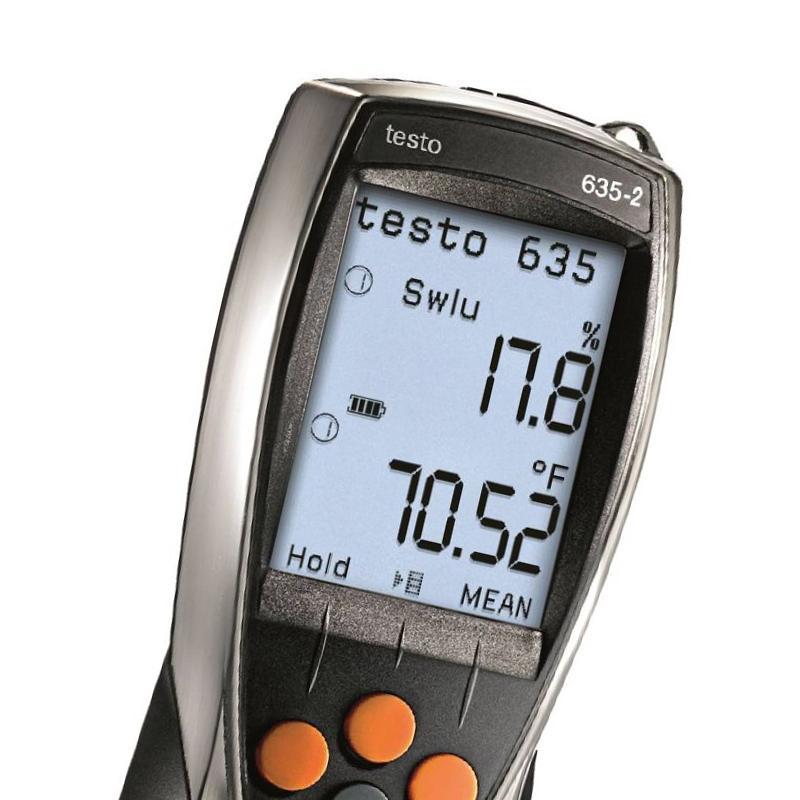

TESTO testo 635-2 Humidity Tester with precision pressure dew point probe

testo 0636 9836 Humidity TesterSPEC

testo 0636 9836 Humidity TesterDetails

testo 0636 9836 Humidity TesterPacking list

- SKU

- NB029448

- NTC Measurement range

- -40~+150℃

- NTC Measurement Accuracy

- +/- 0.2 ℃ (-25~ + 74.9 ℃) +/- 0.4 ℃ (-40~ -25.1 ℃) +/- 0.4 ℃ (+ 75~ + 99.9 ℃) +/- 0.5% Measured value (remaining range)

- NTC resolution

- 0.1℃

- Type K (NiCr-Ni) Measurement range

- -200 ~ +1370 ℃

- Type K (NiCr-Ni) Measurement Accuracy

- +/- 0.3 ℃ (-60~ + 6 0 ℃) +/- ( 0.2 ℃ + 0.3% Measured value)

- Type K (NiCr-Ni) resolution

- 0.1 ℃

- Capacitive Humidity Sensors Humidity Measurement range

- 0~100%RH

- Measurement Accuracy of Capacitive Humidity Sensors

- Depending on the probe

- Capacitive Humidity Sensors resolution

- 0.1%RH

- Measurement range

- 0 ~ 2000 hPa

- Measurement Accuracy

- Depending on the probe

- Absolute pressure resolution

- 0.1 hPa

- diameter

- 220*74*46mm

- operating temperature

- -20 ~ +50 ℃

- Shell material

- ABS/TPE/Metal

- Power Supply

- alkaline manganese battery

- Battery life

- 200 hours

- Storage temperature

- -30 ~ +70℃

- Weight

- 428 g

Description

The testo 635-2 thermohygrometer is ideally suited for the inspection of air conditioning systems. A wide selection of sensors and probes can help you measure a variety of parameters, including:

Relative Humidity

Moisture content of the material

The material compensates for moisture

Pressure dew point of compressed air systems

U-value

Air temperature

Surface temperature

Core temperature

Absolute pressure

The main unit of the instrument can be connected to 2 probes at the same time. The measurement results are displayed instantly on a clear, easy-to-read display.

Robust, practical and easy to use

In addition to measuring a wide range of parameters, the testo 635-2 thermohygrometer also displays maximum/minimum values, average values and calculates the dew point difference between the air in the room and between the wall. You can use this data to analyze the humidity of ceilings and walls. Individually configurable characteristic curves ensure an accurate and reliable display of the moisture content of the material.

The instrument itself and the user interface are easy and comfortable to use. The backlit display ensures that you can easily read the data even when lighting is low, and the rugged housing protects the instrument from external impacts.

Save, transfer and print data – it's easy

The instrument can create a measurement address and store the measured data from the measurement address in the address file. User-specific measurement programs or menus can be created to perform long-term measurements or to measure the moisture content of the material. Up to 10,000 measurement data can be stored in the instrument memory – single or programmed. The standard USB cable allows you to connect your thermohygrometer to your PC, and the PC software allows you to easily and comfortably analyze, manage and archive your data.

If you're looking for something even easier: the optional Testo infrared printer provides data printing anytime, anywhere, on-site.

Precision pressure dew point probe

Description

The pressure dew point is an important criterion to ensure that the compressed air system is working well. The pressure dew point can be determined quickly and accurately using a precision pressure dew point probe with a measuring chamber (in combination with the appropriate measuring instrument).

The probe undergoes a careful adjustment process: in addition to the standard adjustment, it should also be fine-tuned at the factory at a pressure dew point of -40°C.

Connection to the compressed air system via standard plug-in connection (G1/4" female thread according to ISO 228-1) or by test connection screw joint (for vehicle measurements). If necessary, other standard plug-in connections with G 1/4" threads can also be screwed into the measuring chamber. Used for indoor air humidity and temperature measurement.

0636 9836

0636 9836