KAIRDA KA620 Roughness Gauge measurement platform

SEKairDa KA620 Marble measurement platformSPEC

KairDa KA620 Marble measurement platformDetails

KairDa KA620 Marble measurement platformPacking list

- SKU

- NB029483

- Lifting height

- 300 ± 1mm

- return error

- Not more than 1/6 turn of the handwheel

- Flatness of measurement platform

- Level 00

- Measurement platform size

- 400mm×250mm×70mm

- Weight

- 26.5KG

Introduction

This product is one of the main accessories of the portable roughness measuring instrument. It is suitable for the hand-held roughness measuring instrument of the company. It provides a high-precision measuring platform and a column lifting system for it, which can easily adjust the instrument, and its effect will greatly reduce the Difficulty in operation, especially when measuring high-precision parts, the effect will be more obvious. This product is also suitable for users who use roughness measuring instruments from other manufacturers (including foreign manufacturers), but a special connecting part needs to be customized. Of course, special users for other purposes are not excluded. For special sensors, this set of accessories is required for complex and precise adjustments.

Features

·The difference between the lifting and lowering of the column is extremely small

·The lifting of the column is light and flexible

· Accurate and reliable positioning accuracy

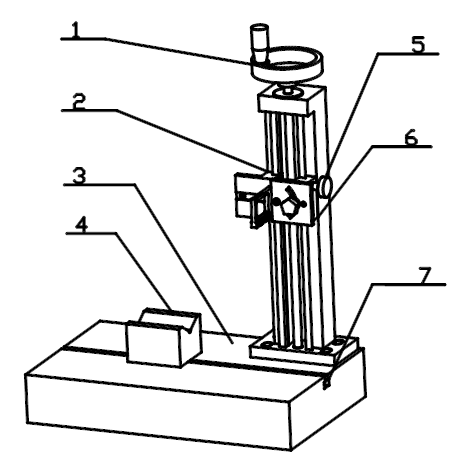

Product Structure

1. Lifting handwheel; 2. Column; 3. Marble platform; 4. V-shaped block; 5. Column locking handwheel; 6. Carriage; 7. T-slot

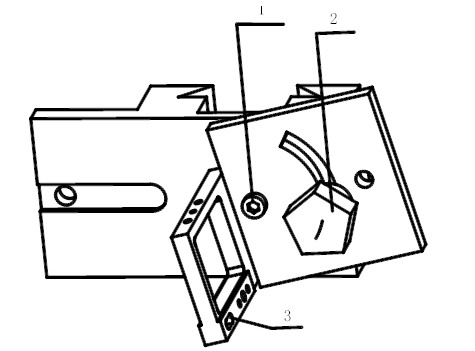

1. Select shaft; 2. Lock nut; 3. Driver connecting plate

Principle

The operator drives the screw nut system to move by turning the lifting hand wheel, the nut is connected to the carriage, and the carriage is connected to the instrument, thus driving the instrument to move up and down along the precision dovetail guide rail. Because the screw nut system adopts a special design to eliminate the gap, the lifting return difference is adjusted to be very small, so the lifting adjustment accuracy of this system is very high. Centering and thrust bearings are used to improve the smoothness of rotation.

- 1JJF 1105-2018《Calibration Specification for Contact(Stylus)Instruments of Surface Roughness Measurement by Profile Method》

- 2JJG 2018-1989《Measuring Instruments for Surface Roughness》

- 3HB 6172-1988《General surface roughness》

- 4GB/T 42671-2023《Test method for surface roughness of carbon materials》

- 5QB/T 2693-2005《QB/T 2693-2005》

KA620

KA620