LEBO PF400 Experimental Film Applicator Vacuum adsorption

-

China bar Vacuum chuck Coater TBJ-A3-XB with imported bar$ 2421.00SE

China bar Vacuum chuck Coater TBJ-A3-XB with imported bar$ 2421.00SE -

China TBJ-G bar Lab Film Applicator Touch + Vacuum chuck Perovskite Solar Cell Moulding$ 2421.00SE

China TBJ-G bar Lab Film Applicator Touch + Vacuum chuck Perovskite Solar Cell Moulding$ 2421.00SE -

China Vacuum chuck Coater TBJ-X2-XB bar + Drawdown blade with imported bar$ 3125.00SE

China Vacuum chuck Coater TBJ-X2-XB bar + Drawdown blade with imported bar$ 3125.00SE -

GB/T 9756 Paint Film Automatic Coating Machine with Vacuum chuck Polyester film finish coating board$ 3204.00SE

GB/T 9756 Paint Film Automatic Coating Machine with Vacuum chuck Polyester film finish coating board$ 3204.00SE -

China TBJ-X1 Vacuum chuck Drawdown blade Film Applicator Lithium battery small Coater$ 2812.00SE

China TBJ-X1 Vacuum chuck Drawdown blade Film Applicator Lithium battery small Coater$ 2812.00SE

lebo PF400 Film ApplicatorSPEC

lebo PF400 Film ApplicatorDetails

lebo PF400 Film ApplicatorPacking list

- SKU

- NB029537

- Coating speed

- 0~300mm/s

- Speed regulation Accuracy

- 1mm/s

- Spreader trip

- 420mm

- Vacuum Area

- 540*345mm

- Vacuum Area

- A4/A3

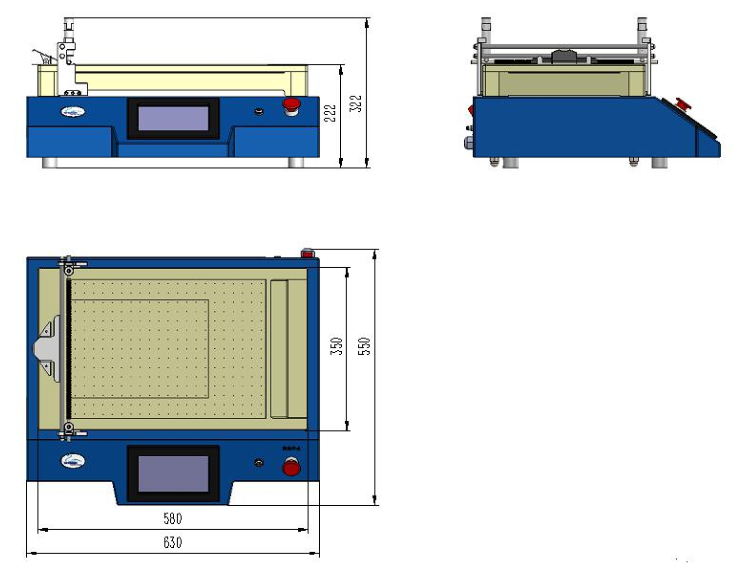

- Dimension

- 630*550*324mm

- Weight

- 30Kg

- Host Power Supply

- AC200V~ 240V, single phase, 50Hz, 400W

- Vacuum input requirements

- 0.06-0.09Mpa

- Vacuum Flow rate

- 15L/Min or more

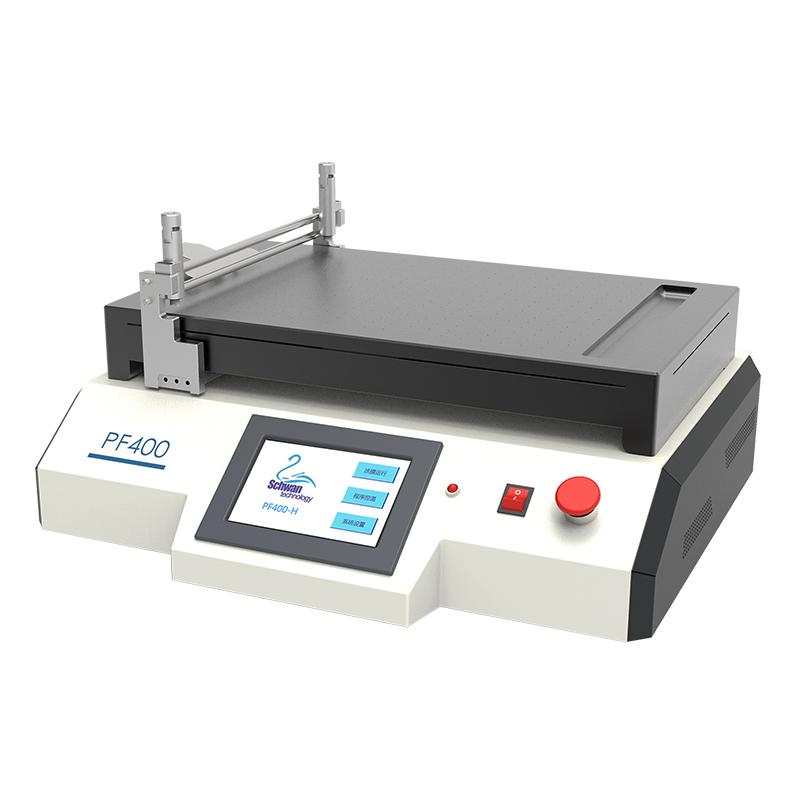

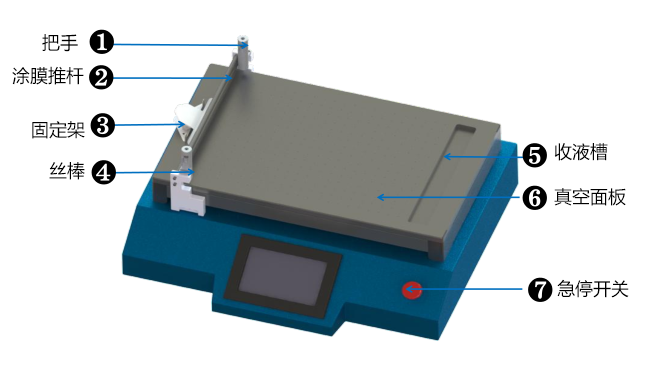

The PF400 coater is used to prepare a uniform coating film because the factors that affect the coating film are the shear rate and the additionThe weight on the construction tool. The device uses a precisely controlled wire rod or applicator at a selected speeddegrees to move back and forth. Since the test strip is flatly adsorbed on the flat plate and the shear rate and application of the film are applied during the coatingThe force on the coating remains constant, which greatly improves the reproducibility of the coating film. At the same time, the aluminum alloy mirror is grindingFlat panels to ensure a flat panel.

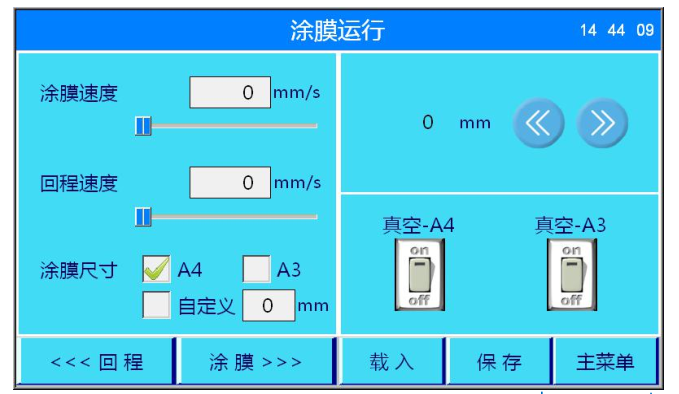

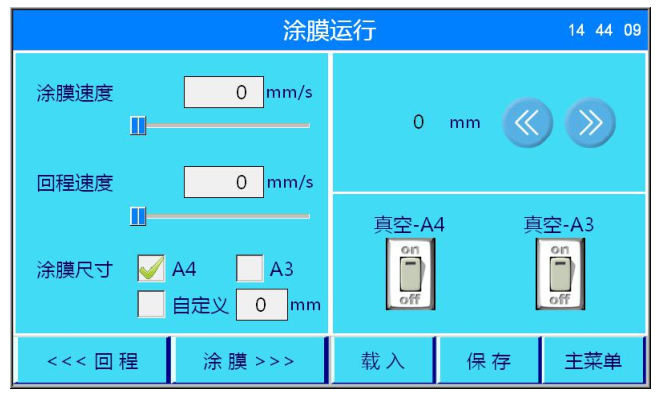

Interface features

The PF400 Film Applicator utilizes a designed vacuum piping system to connect an external Vacuum Pump to a vacuum panel.The substrate can be tightly adsorbed on the vacuum panel by vacuum negative pressure. The customer can choose according to the size of the substrateAdjust the vacuum adsorption range using A4 or A3.

Loading the coating process

When you press the "Load" button on the coating operation screen, you will be taken to the interface shown in the image below.

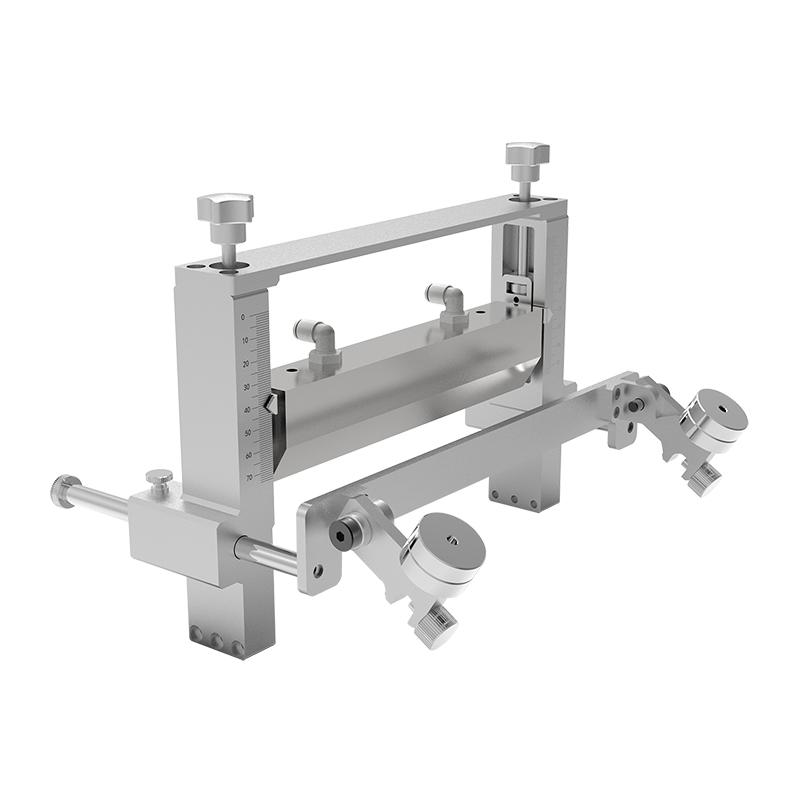

Attachment selection

Four specifications of adjustable Film Applicator are available, the wet film range is 0-3500μm, and the film width is 55mm.100mm, 150mm, 200mm four kinds of options. Other specifications need to be customized.

The length of the wire bar applicator is 400mm, and the wet film thickness is available in a variety of specifications (range from 6 to 200 μm).

A VPC200 Vacuum Pump is supplied as standard.

Optional

- 1Automatic coating machine _ vacuum adsorption small coating machine how to install Vacuum Pump?

- 2Demonstration video of coating operation of small coater on ultra-thin diaphragm

- 3Preparation of Multilayer Medical Polymer Materials by Wire Bar Coater

- 4Preparation of PTFE Foam Coated Glass Fiber Composite Filter Material by Scraper Film Coater

张月 - 《东华大学》

- 5Preparation of foam coatings on fabric surfaces with a coating machine

- 6Preparation of electrode pads with a scraper coating machine

- 7Analysis experiment of the influence of titanium dioxide on the gloss of the coating film applied by the automatic coating machine

- 8Use a film coating machine to apply slurry on aluminum foil, have you encountered this embarrassment?

- 9What type of coating is suitable for the wire mesh coater?

- 10Coating machine case | Coating force Paint on cardboard

PF400

PF400