JINGKELIAN QCJ-120 film impact test 120cm/1000g GB/T 1732

SEJingKeLian QCJ-120 Film impact TesterSPEC

JingKeLian QCJ-120 Film impact TesterDetails

JingKeLian QCJ-120 Film impact TesterPacking list

- SKU

- NB029649

- Impact height

- 120cm

- Impact height

- 120cm

- Graduation

- 1cm

- Drop Weight Mass

- 1000g

- Striker Diameter

- F8mm

- Impact depth

- 2mm

- die base aperture

- F15mm

- radius of curvature

- R2.5-3mm

- Standards

- GB/T 1732-1993

Introduction

The QCJ-120 (120A, 120B) series paint film impact Tester is used for the paint film impact resistance test represented by the maximum height of 120 cm when a weight with a fixed mass falls on the test plate without causing damage to the paint film. After the impact head of this instrument impacts the test plate, there is no secondary rebound phenomenon.

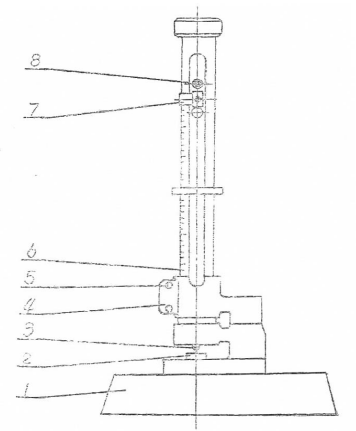

The main structure

1. Base; 2. Pillow block; 3. Punch rod; 4. Support arm; 5. Screw; 6. Slider; 7. Positioning mark; 8. Controller component

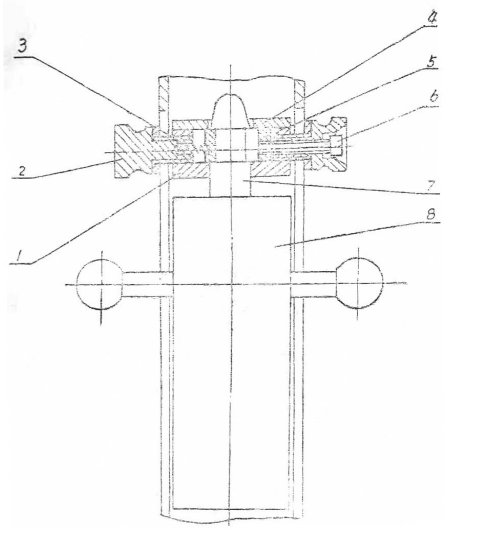

1. The lower bottom of the controller; 2. The electrical part of the controller; 3. The spring of the controller; 4. The upper cover of the controller; 5. The slider of the controller; 6. The control screw; 7. The hook; hammer assembly

Principle

The weight with the hook is fixed at the required height by the controller screw, and its height is that the height mark line shown on the slider scale coincides with the positioning mark line. Press the control screw to compress the spring of the controller. At this time, the round hole of the control slider is aligned with the round hole of the upper cover of the controller and the round hole of the lower bottom of the controller, so that the hook falls off, the weight falls, hits the punch, and the punch acts downward. On the test plate previously placed on the pillow blocks. Afterwards, lift the weight body and take out the test panel to observe the test condition of the paint film on the test panel.

QCJ series impact Tester parameter comparison

| Instrument model | QCJ-120 type | QCJ-120A type | QCJ-120B type |

| Instrument scale length | 120±0.2cm | 120±0.2cm | 120±0.2cm |

| graduation | 1cm | 1cm | 1cm |

| Hammer mass | (1000±1) g | (1000±1)g | (2000±2)g |

| Impact head specification | S diameter 8mm | S diameter 16mm | S diameter 16mm |

| Pillow Block Hole Diameter | 15mm | 15mm | 16.3mm |

| radius of curvature | R2.5-3mm | R2.5-3mm | R2.5-3mm |

| Impact depth of impact head | (2±0.1) mm | (2.5±0.1)mm | (2.5±0.1)mm |

| hospitality standard | GB/T1732—93 Test method for impact resistance of paint film | GB/T5237.4-2000 Aluminum Alloy Architectural Profiles Part 4 Powder Coated Profiles | ASTM D2794-92 Test method for resistance to rapid deformation (impact) of organic coatings |

- 1JJF 002-2015《Calibration Specification for Film Impact Testers》

- 2JB/T 7455-2007《Unsaturated polyester putty for decorating of machine tool》

- 3JG/T 512-2017《General technical requirements for building exterior wall coating system》

- 4SH/T 3022-2019《Design standard for anticorrosion coating of equipment and piping in petrochemical industry》

- 5WJ 2669-2005《Specification for cathode electrophoresis paint for shell》

- 6ASTM 《Standard Specification for Aluminum Particle-Filled Basecoat/Organic or Inorganic Topcoat, Corrosion Protective Coatings for Fasteners》

- 7JT/T 821.1-2011《Anti-corrosive coatings for concrete bridge surface.Part 1: Solvent based coatings》

- 8DL/T 2308-2021《Technical specification for conductive anticorrosion coating for grounding in power engineering》

- 9JG/T 224-2007《Anticorrosive coatings for building steel structure》

- 10HG/T 5060-2016《Anticorrosive coatings for liquified natural gas (LNG) tanks》

QCJ-120

QCJ-120