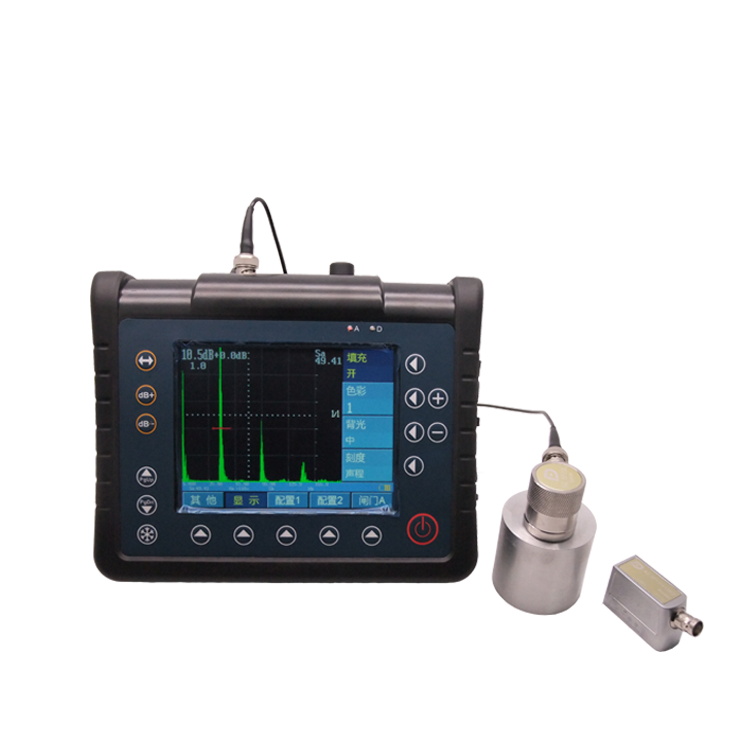

PORUIKE VUT900A high-precision Ultrasonic Flaw Detector

PoRuiKe VUT900A Ultrasonic Flaw DetectorSPEC

PoRuiKe VUT900A Ultrasonic Flaw DetectorDetails

PoRuiKe VUT900A Ultrasonic Flaw DetectorPacking list

- SKU

- NB029788

- Horizontal Linearity

- <0.1%

- Vertical Linearity

- <3%

- Sensitivity margin

- >62dB

- Dynamic range

- >32dB

- electrical noise level

- <20%

- Far field resolution

- >36dB

- Operating Mode

- Single crystal, double crystal mode and penetration mode

- Transmit pulse

- negative spike

- Frequency range

- 0.5MHz~20MHz

- Frequency of sexual repeability

- 25Hz~1000Hz

- Sampling Frequency

- Hardware real-time sampling Frequency 400MHz

- Scanning range

- 0.5~9999mm

- Speed of sound

- 1000~15000m/s

- scan delay

- -10Mm~ 1000mm, continuously adjustable, can switch step

- probe delay

- 0μs~199.9μs

- impedance matching

- 25Ω、50Ω、200Ω、500Ω

- Gain Range

- 0dB~ 110dB, 0.1/0 5/2.0/6.0 step adjustment

- Detection method

- Bidirectional, positive, negative, radio frequency

- Display

- 5.7 "high luminance TFT, 640 x 480 pixels

- Measurement mode

- Frontier or peak

- parameter storage

- Can store commonly used flaw detection parameters and test result data

- Alarm function

- Hardware alarm, sound and light two ways, can set incoming wave, loss wave, DAC alarm mode

- Communication interface

- USB interface and Ethernet interface

- Operating temperature

- -20~50℃

- Power Supply

- Lithium battery (10.8 V, 5.2Ah), can last for more than 8 hours

- Power Supply

- AC 100-240V, DC 14V-3A

- Machine Weight

- 1.4KG (including battery)

- Menu Language

- Simplified Chinese/English

Overview

The VUT-900A high-precision intelligent ultrasonic solder joint Detector is designed with full consideration of ergonomics, strong and lightweight structure, comfortable to carry, and shock-proof. The buttons and menus are set scientifically and reasonably, and the common functions are simple to operate and easy to use, which can greatly improve work efficiency and reduce labor intensity. The products are designed and produced according to the requirements of the European general standard EN12668-1, and have the advantages of high performance, good stability, complete functions and practicality, reliable quality and strong anti-interference ability. The instrument fully complies with the requirements of various industry standards, and is well received by users at home and abroad, and the software is upgraded to VA0.20 version to use and operate more conveniently and smoothly. The instrument is equipped with the original imported lithium battery, no memory effect, high capacity, and the continuous working time of the battery can reach 8 hours or more, which is an excellent choice for testing operations, especially field operations.

Features

DAC curve generation, storage, and recall functions: Simple to make: take points one by one, and automatically generate four curves: evaluation line, quantitative line, DAC bus, and scrap line Easy to edit: each sampling point can be corrected independently, and the curve spacing can be adjusted independently (to adapt to various standards)

AVG curve generation, storage, and recall functions

Simple to make: > 3N area sampling point can automatically generate a curve, < 3N area sampling point by point to form a curve to ensure the practicability of the curve

Easy to apply: the curve equivalent is autonomously adjustable, and the defect equivalent Φ value is automatically calculated

RF display function: the original waveform is displayed realistically, which is convenient for detailed analysis of echo characteristics and auxiliary qualitative analysis of defects

Surface correction function: automatically correct the curved surface detection results

Peak memory function: helps record the highest echoes

Envelope function: record the change trajectory of the echo

Automatic Echo Spectrum Test: It can be used to test the center frequency of the probe echo and its spectral characteristics

Automatic gain adjustment function: the automatic gain height can be adjusted by itself to achieve quick adjustment of the echo height • Weld inspection graphic function: intuitive graphic display, defect location at a glance, pictures can be stored in the flaw detection report, playback and printing are very convenient

Intelligent equipment calibration procedures: including quick calibration of material sound velocity, automatic measurement of probe delay, automatic calibration of probe angle and K value, making it easier to calibrate the probe

Quick channel setting function: 30 sets of flaw detection parameters can be set and stored in 30 fast channels, which is convenient for storage and recall

Automatic report generation function: The system generates a flaw detection report according to the flaw detection parameters and test data, which contains detailed flaw detection parameters, waveform images and echo data, and can be directly connected to the printer to print the report, or save it in the computer

Continuous storage and playback function: record the dynamic waveform of the detection process to make the data recording more detailed; The menu setting similar to the camera function is easy to understand and easy to operate, and the stored files can also be directly transferred to a USB flash drive and other storage devices at any time

Waveform display area zoom function: The waveform display area can be enlarged to the full screen, which can effectively prevent misoperation during on-site flaw detection

Gate area magnification function: zoom in the gate area to the entire waveform display area, which is convenient to observe the waveform details

Main uses:

It is widely used in machinery manufacturing, iron and steel metallurgy, metal processing industry, chemical industry and other fields that require defect detection and quality control

It is used in in-service safety inspection and life assessment in aerospace, railway transportation, boiler and pressure vessel and other fields

It is suitable for ceramics, plastics, glass, adhesives, carbon fiber, cemented carbide and other materials

Operating Conditions

Ambient temperature: operating temperature -20°C~+50°C

Storage temperature: -30°C~+70°C

Relative Humidity≤90%

There is no strong vibration, no strong magnetic field, no corrosive medium and no serious dust in the surrounding environment

- 1What is an ultrasonic pulse echo system?

- 2Ultrasonic Flaw Detectors: the right-hand man for nondestructive detection

- 3The working principle and application of eddy current Flaw Detector

- 4Basic Principle Characteristics and Application Analysis of Flaw Detector for Casting

- 5Application of Ultrasonic Flaw Detector

VUT900A

VUT900A