MODERNER PPH-1000 Combined Pencil Hardness Tester

-

LANDTEK HT-6510P Pencil hardness Tester film Hardness detection$ 132.00SE

LANDTEK HT-6510P Pencil hardness Tester film Hardness detection$ 132.00SE -

TRUIT TR 5100/1 Pencil Hardness Tester 500g$ 173.00SE

TRUIT TR 5100/1 Pencil Hardness Tester 500g$ 173.00SE -

PUSHEN BY Combined Pencil Hardness Tester 500g/750g/1000g with Mitsubishi pencil$ 200.00SE

PUSHEN BY Combined Pencil Hardness Tester 500g/750g/1000g with Mitsubishi pencil$ 200.00SE -

Pencil Hardness Tester AMITTARI AS-120P Load weight 1000g /750g /500g$ 139.00SE

Pencil Hardness Tester AMITTARI AS-120P Load weight 1000g /750g /500g$ 139.00SE -

QHQ-3084 Pencil Hardness Tester QHQ-3084 (500g/750g/1000g) JFL$ 200.00SE

QHQ-3084 Pencil Hardness Tester QHQ-3084 (500g/750g/1000g) JFL$ 200.00SE

Moderner PPH-1000 Pencil Hardness TesterSPEC

Moderner PPH-1000 Pencil Hardness TesterDetails

Moderner PPH-1000 Pencil Hardness TesterPacking list

- SKU

- NB029837

- Load

- 500/750/1000g

- Applicable standards

- GB/T 6739-1996

- material

- metal

- Standard pencil

- 6B-6H(13支)

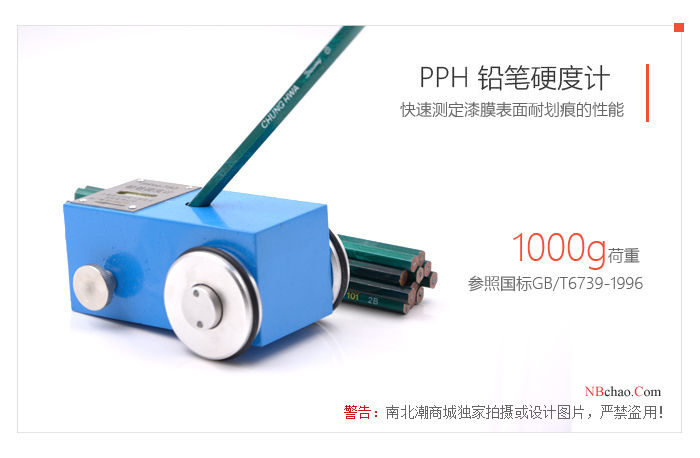

PPH-1000G Pencil Hardness Tester Overview

MODERNER PPH-1000 combined pencil Hardness Tester is designed and produced in strict accordance with the standards of GB/T6739-1996 "Pencil Measurement Method for Paint Film Hardness" and is used to test the surface scratch resistance of paint films. The PPH-1000 combined pencil Hardness Tester has pencil lead pressures of 1000g, 750g, and 500g, and is equipped with pencils with more than ten hardnesses from 6B to 6H.

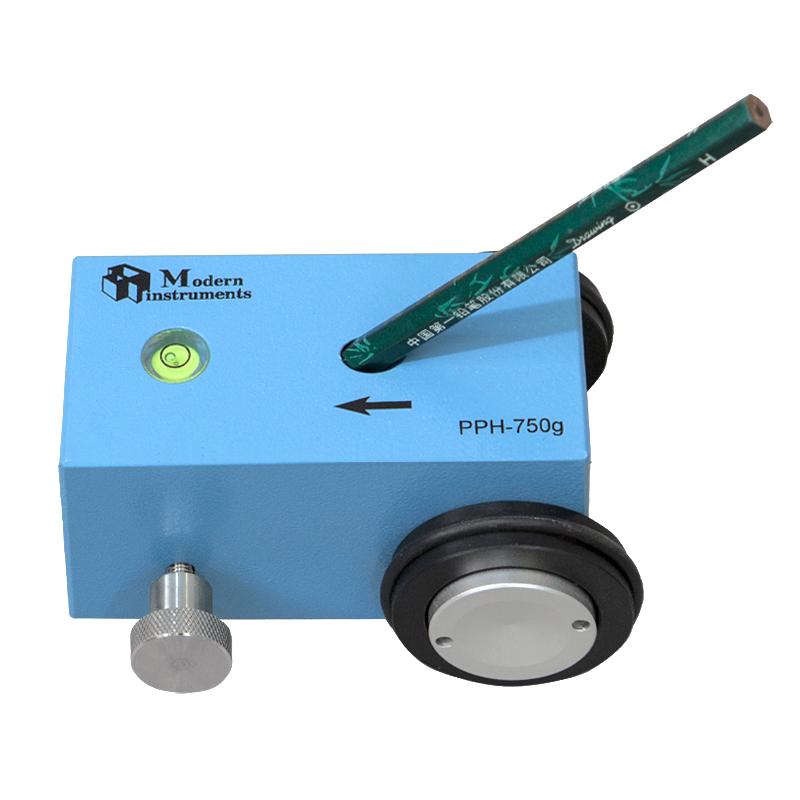

Actual pictures of PPH-1000G pencil Hardness Tester

Structure and Principle

PPH-1000 pencil scratch Tester uses three points of contact with the tested surface (two points are the rollers and one point is the pencil lead). The angle between the pencil and the tested surface is 45°. When the horizontal bubble is horizontal, the pressure exerted by the main body on the pencil lead is 1000±50 grams. The hardness of a paint film is determined by passing a pencil with a known hardness scale across the paint film.

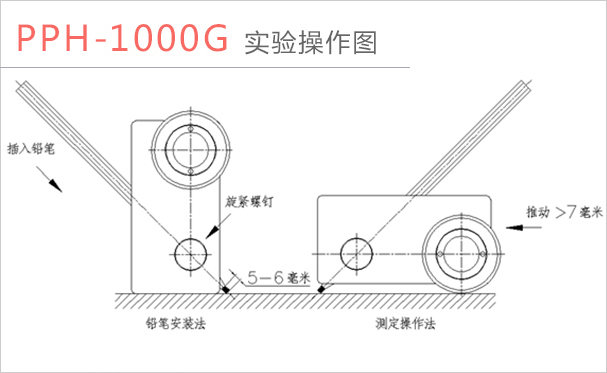

experiment procedure

1. Prepare the substrate in accordance with the provisions of GB/T9271 "Standard Test Panels for Paints and Varnishes".

2. Sharpen the pencil until 5 to 6 mm of the lead is exposed (maintain the cylindrical shape of the lead). Keep the pencil perpendicular to the sandpaper to grind the end face of the lead until the end face becomes a complete circle with no broken or chipped edges. Pencils must be sharpened in this way before each use.

3. Unless otherwise agreed, measurements shall be made at 23±2 degrees Celsius and 50±5% humidity.

4. Install the pencil according to the attached figure, push it at least 7 mm at a speed of 0.5~1 mm/second, and use the marked hardness of the hardest pencil that does not cause scratches of 3 mm or more on the paint film to indicate the pencil hardness of the paint film.

5. Measure twice in parallel. If the results of the second measurement are inconsistent (the difference exceeds 1 pencil hardness unit), the test should be repeated.

PPH-1000 pencil configuration

Each instrument is equipped with: 13 high-end drawing pencils (6H ~ 6B).

PPH-1000 pencil Hardness Tester maintenance

1. This PPH-1000 pencil Hardness Tester strives to rotate flexibly when used. After using it for a period of time, oil must be injected into the rotating parts such as the screw rod and bearings.

2. After using this PPH-1000 pencil Hardness Tester for a period of time, the set screws and nuts must be tightened to avoid loosening.

PPH-1000

PPH-1000