HONEYEAGLE HNAG1000-ETO Fixed ethylene oxide Detector 0-500PPM

SEhoneyeagle HNAG1000-ETO(0-500PPM) Ethylene oxide DetectorSPEC

honeyeagle HNAG1000-ETO(0-500PPM) Ethylene oxide DetectorDetails

honeyeagle HNAG1000-ETO(0-500PPM) Ethylene oxide DetectorPacking list

- SKU

- NB029979

- Sensors principle

- Electrochemistry

- Detect gas

- ETO

- Sampling method

- Diffusion

- Range

- 0~500ppm

- Detection Accuracy

- ±2%F.S

- Repeatability

- ±1%F.S

- Operating temperature

- -30~50℃

- Storage temperature

- -40~70℃

- Operating current

- ≤50mA

- Installation method

- fixed installation

- output interface

- many

- service life

- 3-5 years

- Baud rate

- 9600

- Response time

- <10s

- Environmental humidity

- 0~95% RH non-condensation

- Long term drift

- ≤±1%(F.S/年)

- Warm-up time

- 10s

- Operating Pressure

- 86kpa-106kpa

- Shell material

- Aluminum alloy flameproof shell

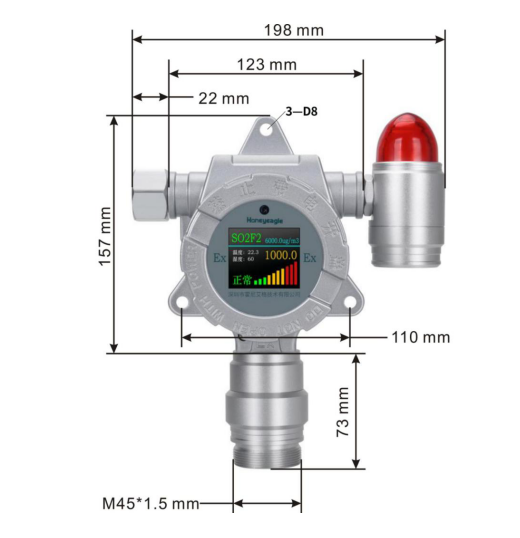

- Dimensions

- 183*143*107mm

- Weight

- 1.5Kg

- Output signal

- Standard: RS485, 4-20mA

- Sensors brand

- Honeywell

- Power Supply

- DC5V±1%/DC24±1%

- Accuracy

- 0.1ppm

- Explosion-proof sign

- Ex d IIC T6

- Protection level

- IP66

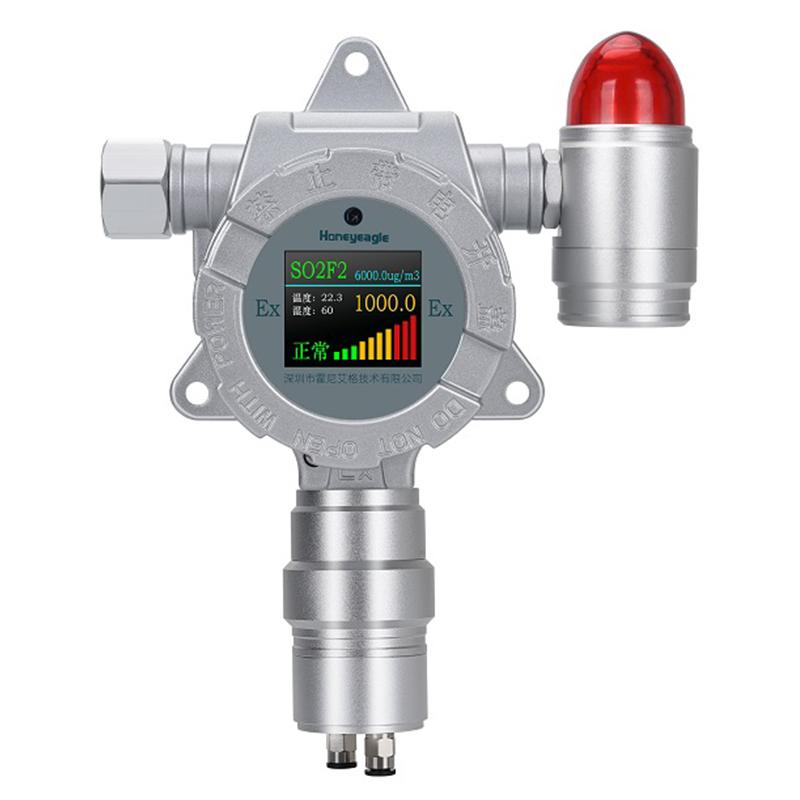

- LCD display content

- Measurement of gas name, real-time value, 50-segment histogram display of real-time gas concentration, gas full scale, gas internal parameters

- Analog signal output

- 3-Wire 4-20mA linear output

- Digital signal output

- Standard RS485 signal output, with Moden and communication software can communicate with the computer

Description

The online ethylene oxide Gas Detector HNAG1000-ETO, which is suitable for real-time and accurate detection of ethylene oxide body concentration and leakage in various environments, adopts imported electrochemical sensor and microcontroller technology. Fast response, high measurement accuracy, good stability and repeatability. The explosion-proof wiring method is suitable for all kinds of dangerous places, and is compatible with various control alarms, PLC, DCS and other control systems, and can realize on-site alarm and early warning at the same time, 4-20mA standard signal output, relay switching output; It is very good to display various technical indicators and gas concentration values; At the same time, it has a variety of strong circuit protection functions, which can effectively prevent the damage of the instrument caused by various human factors and uncontrollable factors.

Features

●Intrinsically safe circuit design, explosion-proof certification, secondary lightning protection, anti-static, lightning protection and anti-static ability exceed the national standard, and resist the impact of high-intensity pulse surge current. High reliability and stability.

●Standard bus RS485 and 4~20mA standard signal output at the same time, 1 group of relay switching output, optional frequency output 200-1000Hz, Hart protocol signal, 1~5V output, wireless transmission (10-50 km or unlimited distance). It can be wired or wireless remote real-time monitoring, upload the data to the mobile phone or transmit it to the Environmental Protection Bureau, other monitoring centers, monitoring equipment, monitoring computers through the local area network and the Internet, and monitor the concentration of the site in real time through free host computer software or gas alarm controller.

●Compatible with various secondary meters, data acquisition modules, PLC, DCS systems, can directly drive solenoid valves, fans, alarms and other equipment, and can also drive high-power equipment by driving intermediate relays.

●Equipped with infrared remote control as standard, it can realize the operation without opening the lid in dangerous situations, such as: modify alarm point, concentration calibration, zero point calibration, silencer, factory reset, and enter the menu.

●2.5 inch high-definition color screen (TF) displays real-time concentration, temperature and humidity.

●Automatic tracking of zero point to prevent drift, temperature compensation, multi-level calibration, can meet the national standard and local and provincial metrology bureau standards in various regions at the same time.

Dimension of ethylene oxide ETO online concentration Detector

Place of application

Petroleum and petrochemical, chemical plants, smelters, iron and steel plants, coal plants, thermal power plants, scientific research, production workshops, tobacco companies, environmental monitoring, school scientific research, building construction, fire alarm, sewage treatment, industrial gas process control, boiler room, garbage treatment plant, tunnel construction, oil pipelines, gas stations, underground gas pipeline maintenance, indoor air quality testing, hazardous place safety protection, aerospace, military equipment monitoring, etc.

Meets standards

In line with EMI and EMC standards, it has passed the national standard test and CMC measuring instrument license certification.

GB 3836.1—2010 General requirements for electrical equipment used in explosive gas atmospheres

GB 3836.2—2010 Electrical equipment for explosive gas atmospheres - Flameproof type "d"

GB 3836.4—2010 "Electrical equipment for explosive gas atmospheres – Intrinsically safe type "i"

- 1How to choose the right Gas Detector?

- 2Effect of Synthetic Polymer Thickener on Viscosity of Styrene Acrylic Latex Paint

梅燕 - 《华南理工大学 化学工程》

- 3The working principle and use and maintenance of toxic and harmful gas alarms

张 瑜 - 《天津联维乙烯工程有限公司》

- 4How to choose the correct installation location for combustible Gas detection instruments?

- 5Comparison of Advantages and Disadvantages of Several Different Working Principles of Gas Detector Sensors

- 6Gas Detectors should be installed like this!

- 7What gases do breweries need to test for?

- 8UV ink composition and UV light source

- 9Gas Detector these introductory skills, have you learned it?

- 10What is a Gas Detector tube and how to use it?

- 1HJ 872-2017《Ambient air.Determination of chlorine and other hazardous air pollutants in emergency monitoring.Electrochemical sensor method》

- 2HG/T 5899-2022《Mixed gas used for disinfection fumigation一 Ethylene oxide in carbon dioxide》

- 3JB/T 11621-2013《Electrochemical gas sensors》

- 4GB/T 20936.3-2017《Gas Detectors for explosive atmospheres—Part 3: Guidance on functional safety of fixed gas detection systems》

- 5GB 3836.4-2010《Explosive atmospheres- Part 4:Equipment protection by intrinsic safety“i”》

HNAG1000-ETO(0-500PPM)

HNAG1000-ETO(0-500PPM)