PORUIKE VUT620A high-precision ultrasonic testing (UTS) instrument

PoRuiKe VUT620A High-precision ultrasonic testing (UT) instrumentSPEC

PoRuiKe VUT620A High-precision ultrasonic testing (UT) instrumentDetails

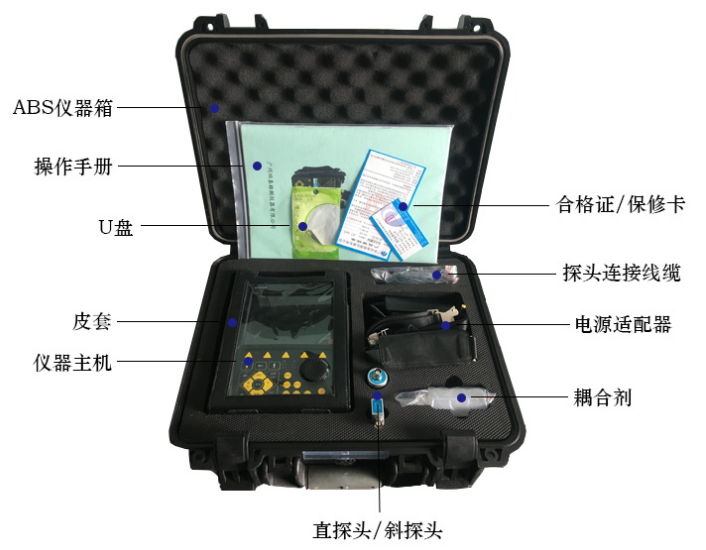

PoRuiKe VUT620A High-precision ultrasonic testing (UT) instrumentPacking list

- SKU

- NB029997

- Scanning range

- 0~10000mm

- Speed of sound

- 1000~9999m/s

- number of storage channels

- 10

- Number of stored waveforms

- 100

- video recording

- 5min×10

- Gain Range

- 0dB~100dB

- display delay

- -15μs~+3400μs

- Probe zero bias

- 0μs~1000μs

- Frequency

- 0.2~15MHz

- impedance matching

- 50/75/150/500Ω

- electrical noise level

- ≤10%

- Frequency of sexual repeability

- Automatic low, automatic medium, automatic high, 5~ 1000Hz

- Flaw Detection Sensitivity Margin

- ≥ 62dB

- Dynamic range

- ≥ 40dB

- Horizontal Linearity

- ≤ 0.1%

- Vertical Linearity

- ≤ 3%

- Far field resolution

- ≥ 32dB

- pulse intensity

- fixed

- pulse width

- 50~1000ns

- Storage Capacity

- 1GB

- Environmental temperature

- -10℃~+50℃

- Operating Time

- ≥20H

- Menu Language

- Simplified Chinese/English

- Communication interface

- High-speed USB interface

- size

- 220×175×59(mm)

- Power Supply

- 7200mAh lithium battery

- Power Supply

- 220V,50Hz,8.4V

- Machine Weight

- About 1.3Kg (including battery)

Overview

VUT620A is a true color display all-digital ultrasonic flaw Detector, which can quickly and conveniently, without damage, and accurately detect, locate, evaluate and diagnose a variety of defects (cracks, inclusions, porosity, etc.) inside the workpiece. It is used both in the laboratory and in the field of engineering. This instrument is widely used in special inspection institutes, construction engineering quality inspection stations, boiler and pressure vessel manufacturing, construction machinery manufacturing, iron and steel metallurgy, steel structure manufacturing, shipbuilding, oil and gas equipment manufacturing and other fields that require defect detection and quality control, and is also widely used in aerospace, railway transportation, boiler and pressure vessel and other fields of in-service safety inspection and life assessment.

Features

Full Chinese display, menu-based operation, multiple shortcut keys, digital shuttle knob. Easy to operate, advanced technology

True color LCD screen, color scheme can be selected according to the environment, and the screen brightness can be set freely

Powered by a detachable battery, it can be charged online, and it can be charged by one extension. Variable working side charging. The battery is easy to replace. It can be used in the field for a long time without worry. It is small in size, light in weight, and easy to carry

Multi-channel flaw detection can be performed, selected channels can be saved for easy management, and waveforms can be stored and recalled at any time

Data storage: It is equipped with storage shortcut keys for easy operation, and can be quickly saved, recalled, played back and deleted

Readings are automatically captured, and when the gate is moved, the gate automatically lassoes the next echo

It has shortcut keys for gain addition and subtraction, which is convenient for adjustment; At the same time, it has an automatic gain function, and the user can reach the preset gain value with one click

Automatic calibration of various probe parameters

There is no restriction on the order of production points for DAC and AVG curves, and it is easy to operate

Transmit pulse: support sharp pulse and square wave transmission, pulse amplitude and width can be adjusted, so that the probe works in a good state. Impedance matching is optional to meet different working requirements of sensitivity and resolution.

Four Operating Modes: single crystal straight probe, single crystal oblique probe, double well straight probe, transmission

Amplify the reception

Real-time sampling: High-speed ADC for full display of waveform details

Wave detection method: full wave, positive half wave, negative half wave, radio frequency

Gate: Dual gate reading, support time gate and sound path gate, automatically capture echoes

Gain: 0-110dB multi-step adjustable. The basic gain, scan gain, and surface compensation can be adjusted separately for easy flaw detection settings. Support gain locking, support automatic gain

Alarm type: gate incoming, gate loss, curve incoming, curve loss, 4 types are optional

Alarm mode: buzzer alarm, flash alarm

Large number display: The user can open the key parameter menu item and select the number that needs to be amplified, such as sound path, depth, etc

Real-time clock recording: Date and time tracking records, and storage

Communication interface: high-speed USB interface provides transmission

Power saving function: The user can set how long the screen will be darkened without operation to achieve the purpose of power saving. When in standby, the user can set how long the instrument screen will turn off automatically, saving power and extending the life of the instrument

Main uses:

1. It is widely used in machinery manufacturing, iron and steel metallurgy, metal processing industry, chemical industry and other fields that require defect detection and quality control

2. It is used in in-service safety inspection and life assessment in aerospace, railway transportation, boiler and pressure vessel and other fields

Diagram of product accessories

Operating Conditions

Ambient temperature: operating temperature -10°C~+50°C

Storage temperature: -30°C~+70°C

Relative Humidity≤90%

- 1Types and Usage Methods of Coupling Agent for Thickness Gauges

- 2Application of Ultrasonic Flaw Detector

VUT620A

VUT620A