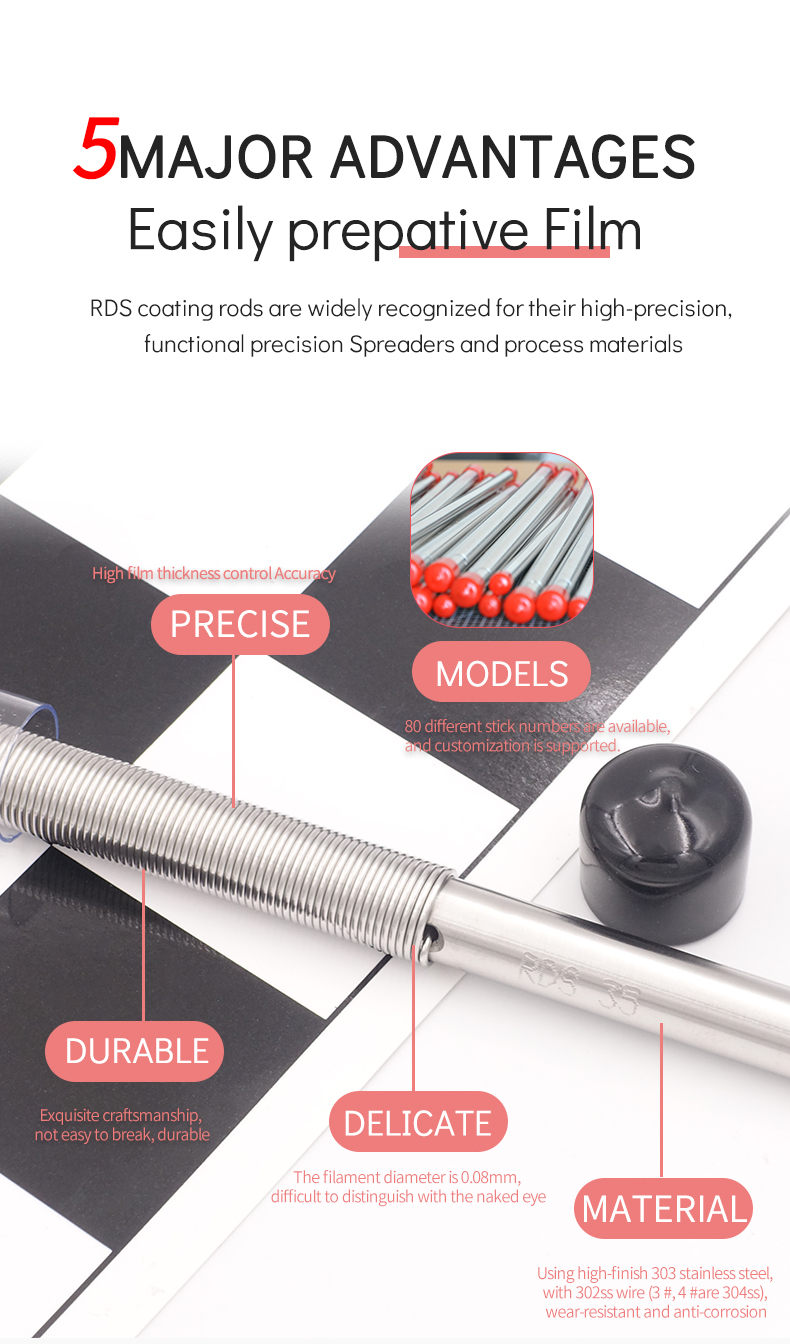

RDS 5 #3/8 "Mayer Rods WFT 11.4μm inks Color Colorimetric

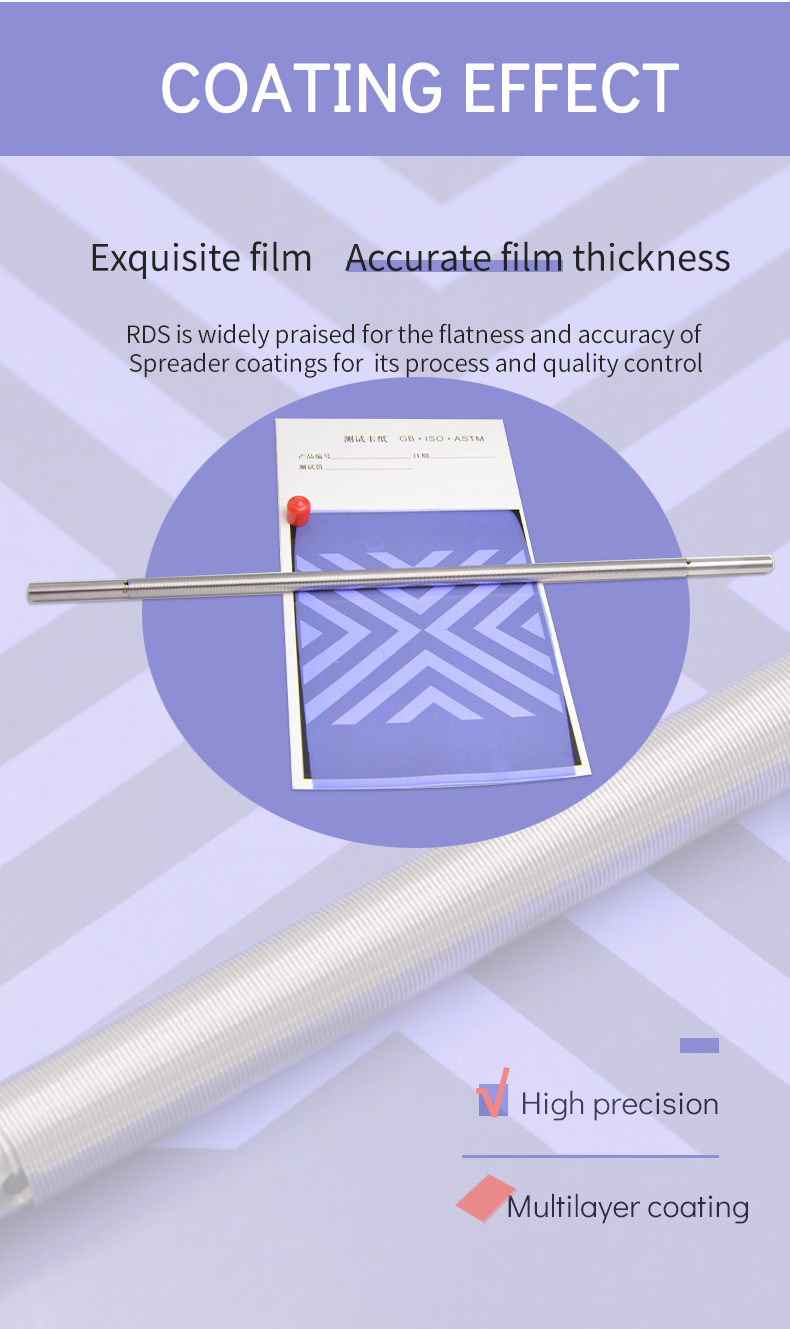

SEMainstream models of inks scraping samples, Mayer wire-wound principle, Wire diameter 0.13mm, about 11 micron wet-film control, suitable for the application of Wire-wound drawdown Bar inspection on inks Color tinctorial strength in the newly released GB/T13217.1 standard in 2020.

$162.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

UK RK KHC.10.2 coating rod WFT 12μm red rubber head No. 2 rod$ 153.00SE

UK RK KHC.10.2 coating rod WFT 12μm red rubber head No. 2 rod$ 153.00SE -

UK RK KHC.11.2 Coating bar WFT 12μm red glue head No. 2 rod$ 168.00SE

UK RK KHC.11.2 Coating bar WFT 12μm red glue head No. 2 rod$ 168.00SE -

RDS 5 #1/4 "wire-wound Applicator rod film thickness 11.4μm Wire diameter 0.13mm$ 156.00SE

RDS 5 #1/4 "wire-wound Applicator rod film thickness 11.4μm Wire diameter 0.13mm$ 156.00SE -

RDS 5 #1/2 "Steel Wire Drawdown Rod film thickness 11.4μm Wire diameter 0.13mm$ 181.00SE

RDS 5 #1/2 "Steel Wire Drawdown Rod film thickness 11.4μm Wire diameter 0.13mm$ 181.00SE -

Pushen XB-I 12μm Wire Bar, Length 240mm$ 98.00SE

Pushen XB-I 12μm Wire Bar, Length 240mm$ 98.00SE

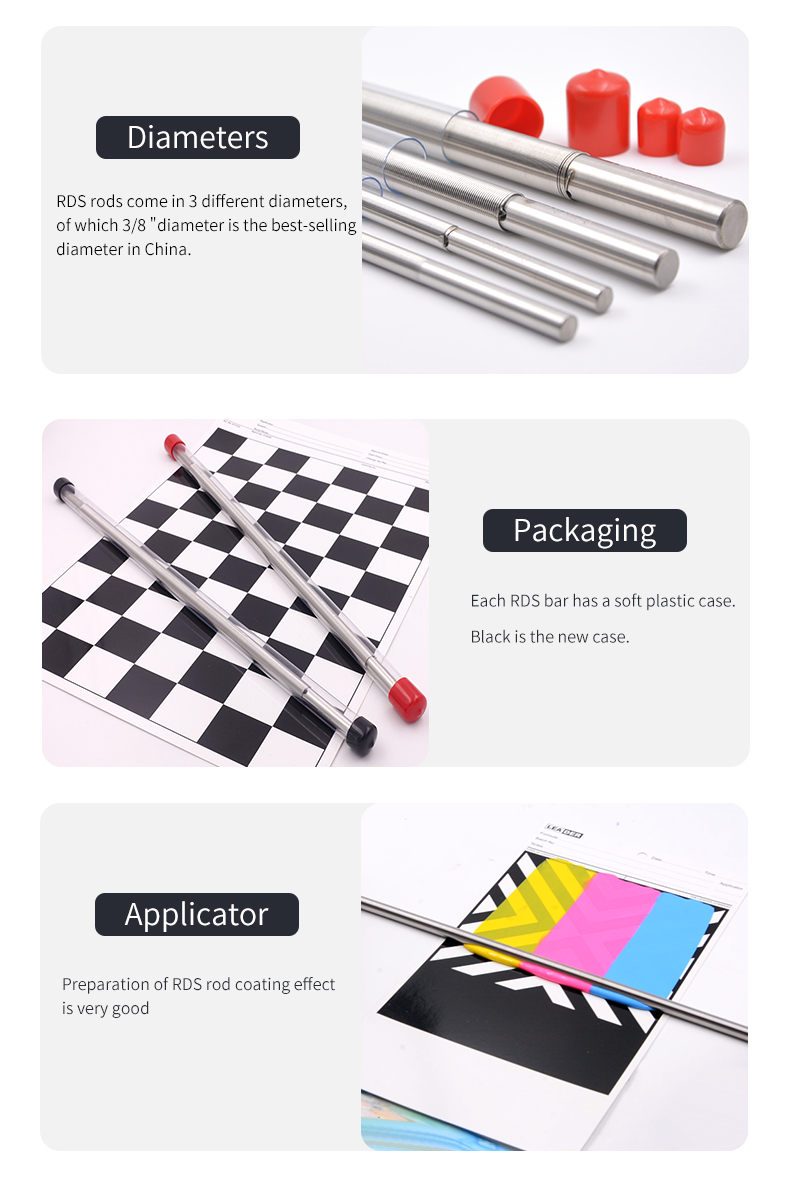

RDS 5# 3/8" Applicator rod 3/8 "SPEC

RDS 5# 3/8" Applicator rod 3/8 "Details

RDS 5# 3/8" Applicator rod 3/8 "Packing list

- SKU

- NB000003

- Production process

- wire-wound

- WFT

- 11.4μm

- diameter

- 9.5mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

- Wire diameter

- 0.13mm

5# 3/8"

Applicator rod 3/8 "

Mainstream models of inks scraping samples, Mayer wire-wound principle, Wire diameter 0.13mm, about 11 micron wet-film control, suitable for the application of Wire-wound drawdown Bar inspection on inks Color tinctorial strength in the newly released GB/T13217.1 standard in 2020.

FAQ

QNeed to prepare about 11μm wet-film coating, which Applicator rod to choose?

A

Recommended RDS No. 5 wire-wound coating rod, wet film thickness is 11.4 μm, stainless steel material is durable and high accuracy, especially suitable for laboratory precision film needs.

QCan Mayer Rods prepare flexible conductive films?

A

Yes, Mayer Rods (Mayer-Rod) can prepare flexible conductive films by electrochemistry.

QIs your RDS5 #wire rod 3/8 inch in diameter?

A

There is.

QThe demand is dry Spreader 0.8~ 1.2 solid contains 0.1 wet Spreader 10g, which stick number is suitable?

A

RDS 4-5 is recommended.

QWhat is the rod diameter of this RDS wire rod in mm?

A

9.5Mm, less than 1cm.

QHow many millimeters thick does this No. 5 one correspond to? I need to apply 4g gram weight, which one is better?

A

RDS 5 #rod corresponds to the wet film thickness of 11.4um, which can be selected through the north and south wet film thickness selection tool

QWhat is the difference between these in RDS 5 #? The Spreader effect is the same, so which one has little impact?

A

It's just that the process and diameter are different, and the Spreader effect is the same.

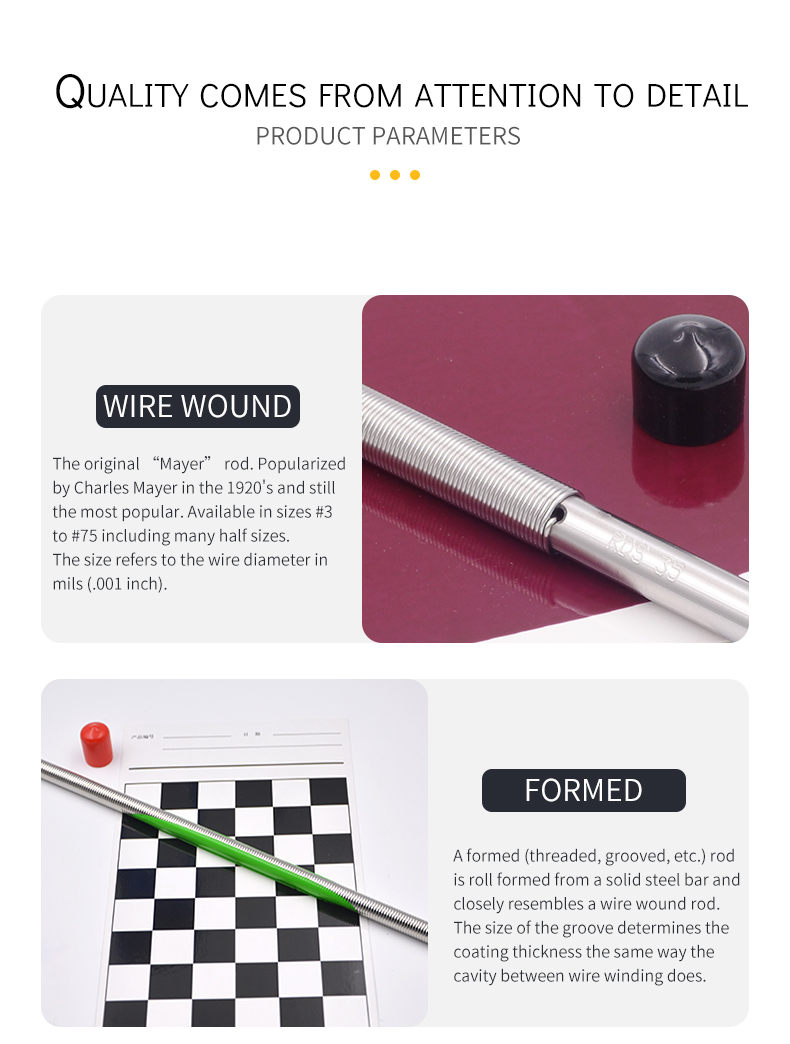

QWhat is the difference between a wire-wound line and a model, and what is the diameter of the wire-wound type? Can the Solid content be increased by adding substances, or is it only related to the solution itself?

A

Wire-wound type is to control different film thickness Spreader by winding different diameter steel wires. The molding type is directly extruded on the smooth steel rod, and the film thickness is controlled by different size grooves. The diameter of the wire-wound determines the different film thickness. Solid content is related to the solution itself, but if you continue to add the original substance of the solution, you can improve the Solid content.

QHang inks samples, what rod is generally used? 15 micron

A

RDS 6 #rods can be used with a film thickness of 13.7 μm.

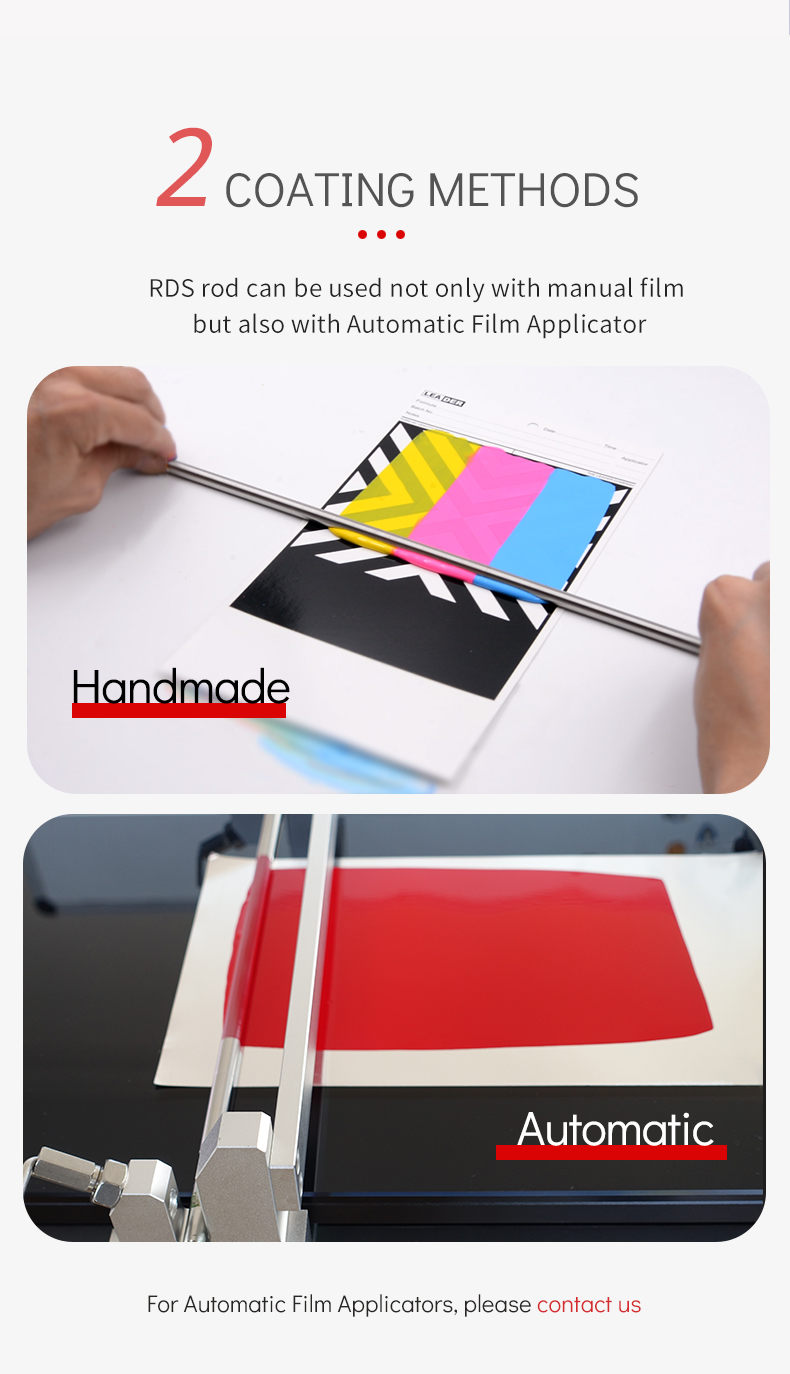

QCan the Small Experimental Automatic Film Applicator for Mouth Film Preparation be matched with this rod?

A

Hello, it's OK.

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- 2Application of Mayer Rods in protective coating prepative

- 3Application of Mayer Rods in Water-based ink Moulding

- 4Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 5Why Do Film Applicators Need to Change Their Wires Regularly?

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6GB/T 21867.3-2008《Pigments and extenders - Methods of assessment of dispersion characteristics - Part 3:Assessment from the change in gloss》

- 7GB/T 13217.1-2009《Test method for colour of liquid ink》

- 8ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 9ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

5# 3/8"

5# 3/8"