PORUIKE BH-200C high-precision Leeb Hardness Tester

PoRuiKe BH-200C High-precision Leeb Hardness TesterSPEC

PoRuiKe BH-200C High-precision Leeb Hardness TesterDetails

PoRuiKe BH-200C High-precision Leeb Hardness TesterPacking list

- SKU

- NB030001

- Impact device

- D type

- Display

- LCD, 128 × 64 graphic dot matrix liquid crystal

- Hardness system

- HL/HB/HRC/HRB/HRA/HV/HS

- Data storage

- Maximum 500 groups

- Power Supply

- 2 AA (No. 5) ordinary alkaline batteries

- meet the standard

- "Leeb hardness Tester technical conditions" JB/T 9378-2001

- Operating temperature

- -10~55℃

- Storage temperature

- -20~+75℃

- Allowable Relative Humidity

- ≤90%

- Measurement range

- 170~960HLD

- Measurement direction

- 360 ° (vertical down, diagonal down, horizontal, diagonal up, vertical up)

- Measurement material

- Steel and cast steel, alloy tool steel, stainless steel, gray cast iron, ductile cast iron, cast aluminum alloy, copper zinc, alloy (brass), copper tin alloy (bronze), pure copper, forged steel

- Power Supply

- 2 × 1.5V ordinary alkaline battery

- Working time

- About 120 hours (when the backlight is not turned on)

- Error of indication

- <6HLD(HLD=760±30);<10HLD(HLD=530±40)

- Indication Repeatability

- <6HLD(HLD=760±30);<10HLD(HLD=530±40)

- Dimensions

- 148*75*32mm

- Weight

- About 0.6kg

Features

Based on the Leeb hardness measurement principle, a wide range of metal materials can be inspected with high precision.

It supports the "Steel" material, and when testing the "Forged Steel" specimen with a D/DC type impact device, the HB value can be read directly, eliminating the need to manually check the table.

It is convenient to switch to all hardness systems (HL, HB, HRB, HRC, HRA, HV, HS) and convert the measured values of each hardness system in parallel.

The large 128×64 graphic dot matrix LCD display is informative and intuitive.

Full Chinese display, menu-based operation, simple and convenient operation.

It has a bright backlit display, which is convenient for use in low-light environments.

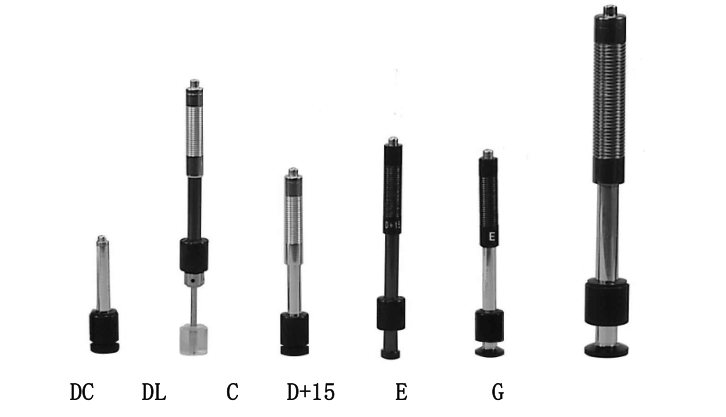

One main unit can be equipped with 7 different impact devices, and the type of impact device can be automatically identified. There is no need to recalibrate when replaced.

Up to 1,000 sets of hardness measurement data can be stored. Each set of data includes information such as a single measurement, an average value, the date of measurement, the direction of impact, the number of times, the material, the hardness system, etc.

The upper and lower limits of hardness values can be set in advance, and automatic alarms will be given when the range is exceeded, which is convenient for users to test in batches.

Small, portable, and highly reliable in the fully sealed plastic housing, suitable for harsh operating environments, resistant to vibration, shock, and electromagnetic interference.

The power supply adopts 2 AA (No. 5) ordinary alkaline batteries, which can work continuously for no less than 120 hours, and has power-saving functions such as automatic sleep and automatic shutdown.

There is a residual power indicator icon on the LCD, prompting the user to replace the battery in time.

It has the function of calibration of the indicator software.

The design is based on the standard: "Technical Conditions for Leeb Hardness Tester" JB/T 9378-2001.

Applications

Installed mechanical or permanently assembled components.

Mold cavities.

Heavy-duty workpieces.

Failure analysis of pressure vessels, turbine-generator sets and their equipment.

Workpieces with a tight test space.

Bearings and other parts.

Formal original records of test results are required.

Material division of metal material warehouse.

Rapid inspection of multiple measuring parts in a large area of large workpieces.

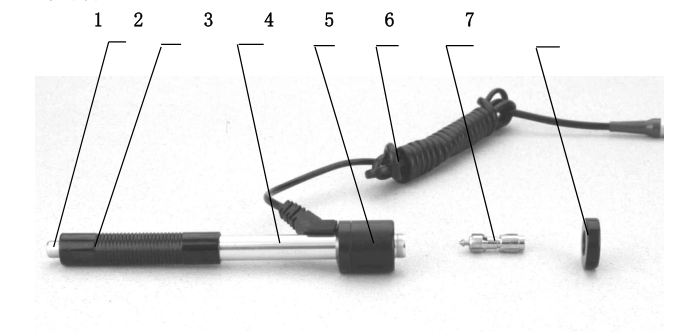

Product structure diagram

Structural diagram of the impact device

1. a release button, 2. a loading sleeve, 3. a conduit, 4. a coil part, 5. a wire, 6. an impact body, 7. a support ring

Other optional impact devices

BH-200C

BH-200C