LINSHANG LS108A lens transmittance Measurement Instrument, infrared inks hole Tester, three-in-one optical path

SELinShang LS108A Lens transmittance Measurement InstrumentSPEC

LinShang LS108A Lens transmittance Measurement InstrumentDetails

LinShang LS108A Lens transmittance Measurement InstrumentPacking list

- SKU

- NB030003

- Diameter of light measurement beam

- Φ1mm

- Infrared peak wavelength

- 850nm/940nm

- Peak wavelength of visible light

- 550nm

- resolution

- 0.1%

- Measurement Accuracy

- ±2%

- Weight

- About 1570 grams

- Host size

- 170*180*144mm

- Power

- DC5V/1A

Introduction

LS108A lens transmittance measuring instrument is mainly used to measure the IR ink hole of the lens of the mobile phone. (It is also applicable to the infrared transmittance test of various infrared technology products, such as remote control window, IR cut, etc.) Nowadays, smart phones generally have two small holes, one for sensing light and the other for sensing distance. The infrared penetration ability of these two small holes will directly affect the performance of the light sensor and the distance sensor. So usually we use a lens transmittance Tester to test its transmittance index.

The testing principle of LS108A is to use infrared 850nm light source, infrared 940nm light source and visible 550nm light source to irradiate the tested transparent material, and the sensor respectively detects the incident light intensity of the three light sources and the light intensity after passing through the tested transparent material. The ratio of the incident light intensity is the transmittance, expressed as a percentage. The test aperture is 1mm, and the size of the measured object is larger than 1mm. Three-in-one light path, three data can be measured at one time for hole alignment.

Product Dimensions

Features

1. The three light sources share one test hole, and are equipped with an alignment indicator LED for auxiliary alignment, and three data can be measured with one alignment.

2. The instrument can measure the transmittance of visible light with a peak wavelength of 550nm, and the transmittance of infrared light with a peak wavelength of 850nm and 940nm. And there are 850nm/550nm/940nm, 550nm/850nm and 550nm/940nm three display modes to choose from.

3. The instrument is mainly used to measure the light transmittance of the IR ink hole of the lens of the mobile phone, and is also suitable for the infrared transmittance test of various infrared technology products, such as the remote control window, IR cut filter, etc.

4. The instrument is equipped with computer software, which can export the test results to the software, and can also use the computer software to judge whether it is qualified or not, and to count the number of tests and the pass rate.

5. The minimum test hole size of the instrument is Φ1mm, which can be used to measure the tested material with a hole diameter larger than 1mm.

6. It adopts super large LCD display, which is convenient for reading.

7. The instrument has real-time dynamic self-calibration function, and it will automatically calibrate to 100% transmittance after starting up.

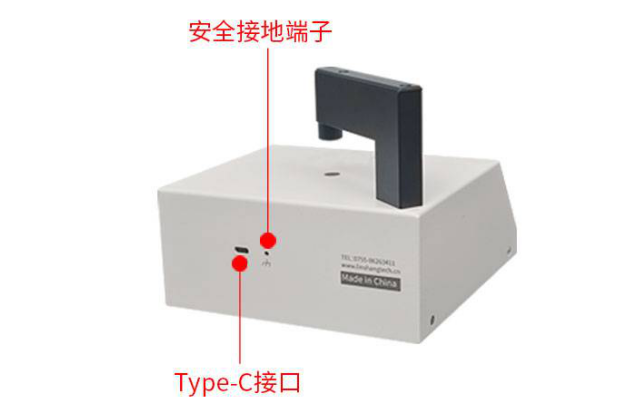

8. It adopts Type-C double-sided pluggable interface, and can also connect to computer software.

- 1GB/T 3830-2024《Calendered film and sheet from flexible polyvinyl chloride》

- 2QB/T 5855-2023《Test for light transmittance of colored glass》

- 3GB/T 10002.1-2023《Unplasticized poly (vinyl chloride) (PVC-U) pipes for water supply》

- 4GB/T 13519-2016《Polyethylene heat-shrinkable film for packaging applications》

LS108A

LS108A