HUXI HR-550JBF Laboratory High Speed Frequency Conversion Grinding Disperser 550W/10L

HuXi HR-550JBF Laboratory High Speed ground DisperserSPEC

HuXi HR-550JBF Laboratory High Speed ground DisperserDetails

HuXi HR-550JBF Laboratory High Speed ground DisperserPacking list

- SKU

- NB030010

- Motor Power

- 550W

- Processing Capacity

- 10L

- Speed range

- 0~8000rpm

- Power supply Voltage

- 220V

- drum

- 1.5L (std.)

1. Introduction

The high-speed disperser is a high-performance product newly developed according to the development trend of international professional dispersing equipment. The equipment integrates the dispersion function and the mixing function, and the two processes of dispersion and grinding are completed by one machine and one container. High efficiency, good mixing effect, easy to clean. Lifting is simple and convenient. It is widely used in the dispersion and mixing of materials in liquids in factories, scientific research institutions, colleges and universities and medical units.

Second, the working principle

This equipment adopts electronic constant force speed regulation circuit, digital direct display of rotating shaft speed, and is equipped with dispersed impeller and grinding disc. It can adapt to the different test needs of the laboratory, and can provide correct process data for large-scale production according to the relationship between the displayed shaft speed and the viscosity of the material and the chemical reaction rate.

Under the high-speed drive of the motor, the dispersing head of this machine produces a high linear speed of rotation tangential, and the material produces strong hydraulic shear and high-frequency mechanical effects under the action of huge centrifugal force, so that the fluid material can withstand thousands of shear and high-frequency mechanical effects per minute, so as to achieve the effect of efficient mixing, dispersion and homogenization.

Working schematic:

3. Scope of application and main technical parameters

| Model | power | Throughput |

| JBF-400W | 400W | 5L |

| JBF-550W | 550W | 10L |

| JBF-750W | 750W | 10L |

| Other parameters | ||

| rotate speed | 0-8000rpm | |

| Voltage | 220V | |

Fourth, the equipment structure diagram

This machine is mainly composed of the following parts:

1. Motor

2. Inverter

3. a lifting bracket

4. Solid grip clamp

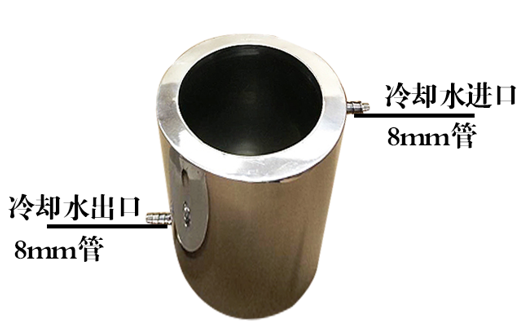

5. Stainless steel barrel

6. Dispersion disc/grinding wheel

HR-550JBF

HR-550JBF