HTechMT CO600FAT5W Film Thickness Gauge iron base, advanced type 500μm

HTechMT CO600FAT5W Coating Thickness GaugeSPEC

HTechMT CO600FAT5W Coating Thickness GaugeDetails

HTechMT CO600FAT5W Coating Thickness GaugePacking list

- SKU

- NB031077

- Measurement principle

- Magnetic Induction

- Measurement range

- 0~500μm

- margin of error

- ±1%

- Probe material

- ruby

- Calibrated mode

- Smooth two-point calibrated, rough two-point calibrated, zero-point calibrated, factory calibrated

- statistical function

- Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation

- Interface

- USB

- Power Supply

- 2 AA batteries (rechargeable batteries can be used)

- Standards

- ISO 2178/2360/2808、ISO 19840、ASTM B244/B499/D1186/D1400

- system language

- Chinese, English, German

- Display screen

- 2.2 TFT LCD screen

- Operating temperature

- -10~50℃

- Battery life

- 20h

- Protection level

- IP64

- Print function

- No

- Machine Weight

- 200g

- Machine size

- 70*150*32mm

- Minimum headroom

- 80mm

- Minimum measurement surface

- R5mm

- Minimum substrate thickness

- 0.8mm

- Test speed

- 60 times/minute

- Probe size

- Φ9mm

- statistical function

- Create a new group, open a group, view a group, clear a group, delete a group, and exit a group

- number of statistical groups

- 100 groups

- Data storage

- Article 1 million

- Other functions

- Data download to PC, WiFi, firmware upgrade

Coating Thickness Gauges provide fast and accurate measurement of non-magnetic coatings or coatings (e.g., e.g., steel, iron) on magnetic metal substrates (e.g., steel, iron).Aluminum, chromium, copper, enamel, rubber, paint, etc.) and non-magnetic metal substrates (e.g. copper, aluminum, zinc, tin, etc.)The thickness of the non-conductive cladding (e.g., enamel, rubber, paint, plastic, etc.).

Executive Standards:ISO 2178/2360/2808、ISO 19840、ASTM B244/B499/D1186/D1400

CO600 series classification

CO600 F A E 1

1 Range type: 1/2/3/4/5 for 1.6, 5.0, 14.0, 25.0 and 0.5 mm (integral and integral strip type)

E: Function Type: Economy (E), Basic (B), Statistical (S), Advanced (T)

A: Main unit and probe connection type: Integral type (A), integral strip type (B) and split type (C)

F: Substrate type: Iron-based (F), Non-ferrous (N)

Split

| B (Basic) | S (Standard) | T (Advanced) | |

| Iron | CO600FCB | CO600FCS | CO600FCT |

| Non-iron-based | CO600NCB | CO600NCS | CO600NCT |

Monolithic

| Range | E (Economy) | B (Basic) | ||

| Monolithic | Integral belt line type | Monolithic | Integral belt line type | |

| Iron-based 0.5mm | CO600FAE5 | CO600FBE5 | CO600FAB5 | CO600FBB5 |

| Iron-based 1.6mm | CO600FAE1 | CO600FBE1 | CO600FAB1 | CO600FBB1 |

| Iron-based 5.0mm | CO600FAE2 | CO600FBE2 | CO600FAB2 | CO600FBB2 |

| Iron base 13.0mm | CO600FBB3 | |||

| Non-ferrous base 0.5mm | CO600NAE5 | CO600NBE5 | CO600NAB5 | CO600NBB5 |

| Non-ferrous base 1.6mm | CO600NAE1 | CO600NBE1 | CO600NAB1 | CO600NBB1 |

| Non-ferrous base 5.0mm | CO600NAE2 | CO600NBE2 | CO600NAB2 | CO600NBB2 |

| Non-ferrous base 13.0mm | CO600NAE3 | CO600NBE3 | CO600NAB3 | CO600NBB3 |

| Range | S (Standard) | T (Advanced) | ||

| Monolithic | Integral belt line type | Monolithic | Integral belt line type | |

| Iron-based 0.5mm | CO600FAS5 | CO600FBS5 | CO600FAT5 | CO600FBT5 |

| Iron-based 1.6mm | CO600FAS1 | CO600FBS1 | CO600FAT1 | CO600FBT1 |

| Iron-based 5.0mm | CO600FAS2 | CO600FBS2 | CO600FAT2 | CO600FBT2 |

| Iron base 13.0mm | CO600FBS3 | CO600FBT3 | ||

| Non-ferrous base 0.5mm | CO600NAS5 | CO600NBS5 | CO600NAT5 | CO600NBT5 |

| Non-ferrous base 1.6mm | CO600NAS1 | CO600NBS1 | CO600NAT1 | CO600NBT1 |

| Non-ferrous base 5.0mm | CO600NAS2 | CO600NBS2 | CO600NAT2 | CO600NBT2 |

| Non-ferrous base 13.0mm | CO600NBT3 | |||

Series differences

| CO600 | E | B | S | T | |

| Coating Thickness Gauge | Economical | Basic | Standard | Advanced | |

| Overview | Dimensions | 70*150*32mm | |||

| Weight (with battery) | 200g | ||||

| display screen | 2.2 TFT | ||||

| battery | 2 x No. 5 batteries (rechargeable batteries available) | ||||

| Battery life1 | 20 hours | ||||

| Operating temperature | -10~50oC | ||||

| precision2 | ±(1-3)% | ||||

| Test speed | 60 times/min | ||||

| Feature settings | Low battery alarm | √ | √ | √ | √ |

| Smooth two-point calibration | √ | √ | √ | √ | |

| Rough two-point calibration1 | √ | √ | √ | ||

| Rough two-point calibration2 | √ | √ | √ | ||

| Zero-point calibration | √ | √ | √ | ||

| Factory calibrated | √ | √ | √ | √ | |

| language3 | √ | √ | √ | √ | |

| Ambient light sensors | √ | √ | √ | √ | |

| Automatic screen transversion | √ | √ | √ | ||

| Test tone adjustments | √ | √ | √ | ||

| Display brightness adjustment | √ | √ | √ | ||

| Upper and lower limit functions | √ | √ | √ | ||

| Screen settings | Screen statistics function | √ | √ | √ | |

| Number of measurements | √ | √ | √ | ||

| maximum | √ | √ | √ | ||

| minimum | √ | √ | √ | ||

| average value | √ | √ | √ | ||

| standard deviation | √ | √ | √ | ||

| Array statistics | Create a new group | √ | √ | ||

| Open the group | √ | √ | |||

| View the group | √ | √ | |||

| Purge groups | √ | √ | |||

| Delete the group | √ | √ | |||

| Leave the group | √ | √ | |||

| Number of groups | 10 groups | 100 groups | |||

| Total storage | 100,000 pieces | 1,000,000 | |||

| other | USB connection to PC | √ | √ | √ | √ |

| Data is downloaded to a PC | √ | √ | |||

| Firmware upgrades | √ | √ | √ | √ | |

| Wifi | √ | √ | |||

1 Different batteries or settings may vary;

2 Accuracy depends on the accuracy of the standard and the user's proficiency;

3 The language is updated without notice, please contact customer service.

Probe selection

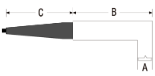

| shape | Probe model | A | B | C | Range | Accuracy 1 | Minimum headroom | Minimum test radius | Minimum substrate thickness |

| CO600F1S | 9 | 40 | 50 | 1.6mm | ± 1-3% or 2.5μm | 80mm | 5mm | 0.8mm |

| CO600F2S | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 80mm | 5mm | 0.8mm | |

| CO600F5S | 9 | 40 | 50 | 0.5mm | ± 1-3% or 2.0μm | 80mm | 5mm | 0.8mm | |

| CO600F1H | 9 | 40 | 50 | 1.6mm | ± 1-3% or 2.5μm | 80mm | 5mm | 0.8mm | |

| CO600F2H | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 80mm | 5mm | 0.8mm | |

| CO600N1S | 9 | 40 | 50 | 1.6mm | ± 1-3% or 2.5μm | 80mm | 5mm | 0.3mm | |

| CO600N2S | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 80mm | 5mm | 0.3mm | |

| CO600N5S | 9 | 40 | 50 | 0.5mm | ± 1-3% or 2.0μm | 80mm | 5mm | 0.3mm | |

| CO600F1R | 9 | 40 | 50 | 1.6mm | ± 1-3% or 2.5μm | 30mm | 5mm | 0.8mm |

| CO600F2R | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 30mm | 5mm | 0.8mm | |

| CO600N1R | 9 | 40 | 50 | 1.5mm | ± 1-3% or 2.5μm | 30mm | 5mm | 0.3mm | |

| CO600N2R | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 30mm | 5mm | 0.3mm | |

| CO600F3S | 16.5 | 40 | 50 | 13.0mm | ± 1-3% or 50μm | 80mm | 10mm | 1.0mm |

| CO600F4S | 24 | 60 | 50 | 26.0mm | ± 1-3% or 100μm | 120mm | 30mm | 1.0mm |

*High temperature probe temperature is 250°C

CO600FAT5W

CO600FAT5W