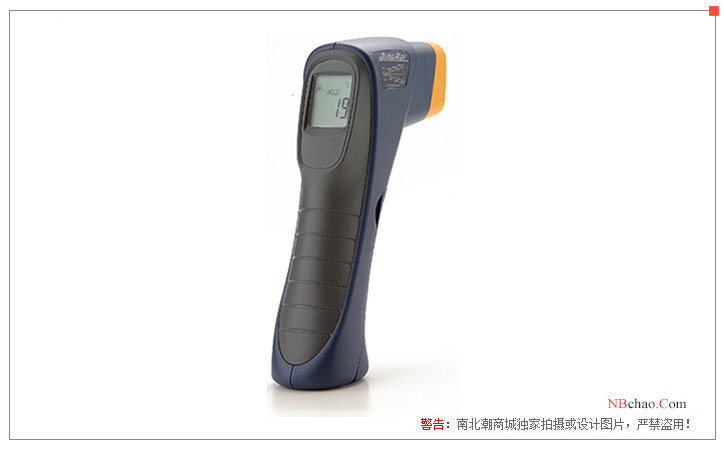

TEC TM-660 Handheld Infrared Thermometer Temperature range -50~999 ℃

KODIN TM-660 Infrared ThermometerSPEC

KODIN TM-660 Infrared ThermometerDetails

KODIN TM-660 Infrared ThermometerPacking list

- SKU

- NB003114

- Temperature Measurement Range

- -50~999℃

- Accuracy

- ±2%

- Resolution

- 0.1℃

- Repeatability

- ±1℃

- object distance ratio

- 12:1

- emissivity

- 0.95

- Response time

- 500ms

- Operating temperature

- 0~50℃

- Storage temperature

- -10~60℃

- Power Supply

- 9V(006P,IEC6F22,NEDA16104)

- Dimensions

- 170*133*45mm

- Weight

- 187g

- thermopile

- 8~14μm

- Battery life

- 16hrs

Introduction of TM-660 Handheld Infrared Thermometer

Compared with the contact temperature measurement method, the TM-660 handheld infrared thermometer has the advantages of fast response time, non-contact, safe use and long service life. TM-660 measuring range: -50~999°C, object distance ratio: 12:1. It will automatically shut down after 6 seconds after no operation, which is convenient for power saving. Two temperature system conversion, backlight display, laser standard, all these bring good enjoyment to your temperature measurement work.

Application

1、Steel. The infrared thermometer is used to continuously measure the entire temperature of the recuperator and the efficiency of the heater. Measure the temperature on both sides of the plate to determine if the heating is uniform. Improve product quality

2. Glass industry. Test the temperature of the furnace to ensure that the glass edge-to-edge temperature is consistent and the glass surface is flat. As a result: ● Increase product yield ● Improve process control ● Improve product consistency ● Reduce downtime

3. Plastics industry. ● Blown film pressing: Accurate temperature test, which can ensure uniform tension resistance and thickness of the plastic ● Lamination and embossing treatment: Use an infrared thermometer to monitor the film temperature and control the heater

4. Heating, ventilation and refrigeration. Using an infrared thermometer: ● Scan the room temperature ● Check the pipe temperature ● Test the temperature of the boiler and evaluate the boiler performance ● Look at the supply and return air circuits

5. Supermarkets or food processing enterprises. Because the storage temperature of refrigerated food is generally below 4.4°C, it may spoil beyond this range. Therefore, it can be easily and quickly checked with an infrared thermometer.

Other applications include: grain processing, food processing, aquatic product processing, alcoholic beverage production enterprises, inspection and quarantine departments, etc.

Product display diagram

TM-660

TM-660