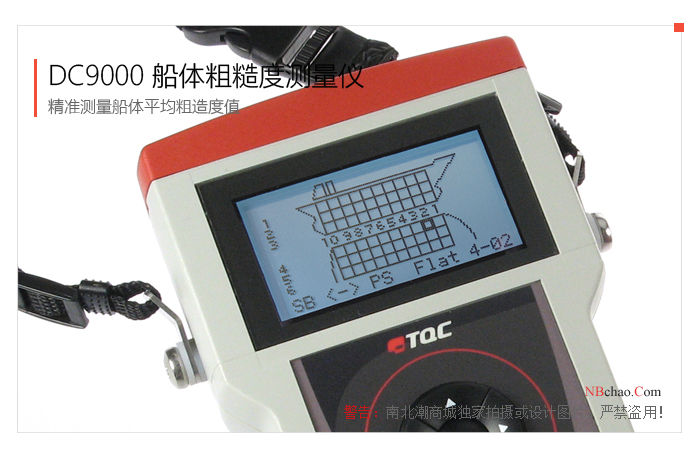

TQC DC9000 Hull Roughometer

SE-

Sand blasting shot peening Roughness Gauge AMITTARI AR-131A shot peening sand blasting, printing anti-corrosion and other industry tests$ 431.00SE

Sand blasting shot peening Roughness Gauge AMITTARI AR-131A shot peening sand blasting, printing anti-corrosion and other industry tests$ 431.00SE -

IPRE RA150 asperity Profile Gauge resolution 0.02μm$ 11826.00SE

IPRE RA150 asperity Profile Gauge resolution 0.02μm$ 11826.00SE -

Surface roughness meter AMITTARI AR-132A high-precision Sensors surface roughness meter$ 980.00SE

Surface roughness meter AMITTARI AR-132A high-precision Sensors surface roughness meter$ 980.00SE -

Surface roughness Tester KAIRDA NDT110 Metal and Non-metallic parts surface roughness testing instrument

Surface roughness Tester KAIRDA NDT110 Metal and Non-metallic parts surface roughness testing instrument -

LANDTEK SRT-6223 sand blasting shot peening Roughness Gauge printing, lame plating$ 466.00SE

LANDTEK SRT-6223 sand blasting shot peening Roughness Gauge printing, lame plating$ 466.00SE

TQC sheen DC9000 RoughoMeterSPEC

TQC sheen DC9000 RoughoMeterDetails

TQC sheen DC9000 RoughoMeterPacking list

- SKU

- NB000312

- Sensors size

- 205×80×40mm

- Sensors Weight

- 630g

- Control Unit Size

- 200×115×40mm

- Control Unit Weight

- ±350g

- Data storage

- Continuously record 4000 values

- screen display

- 80mm

Introduction

The Dutch TQC DC9000 hull surface roughness measuring instrument is a compact system to measure the average roughness value of maritime navigation hulls. The sensor has three anti-skid wheels and a carbide stylus that moves horizontally on the hull, collecting 12 test values ââper group. Statistics, time/date and average roughness of each series of positions are automatically calculated and stored inside the instrument and can be connected to a computer via a USB cable.

Specifications

| model | DC9000 |

| Sensor size: | 205Ã80Ã40mm |

| Sensor weight: | 630g |

| Control unit dimensions: | 200Ã115Ã40mm |

| Control unit weight: | ±350g |

| storage capacity: | Continuously record 4000 values |

| screen display: | 80mm |

Applications

It goes without saying that surface roughness measurement and control play an important role in ship operating costs. Increased hull roughness is caused by corrosion and/or biological fouling. Proper maintenance and correct application of high-end antifouling coatings can effectively reduce surface roughness, which will save fuel consumption and CO2 emissions. For this reason, hull roughness measurements are carried out during berthing at shore and at sea.

Actual pictures

Measurement principle

When the DC9000 hull surface roughness measuring instrument measures the surface roughness of a workpiece, the sensor is placed on the measured surface of the workpiece. The driving mechanism inside the instrument drives the sensor to slide along the measured surface at a constant speed. The sensor senses the surface roughness through the built-in sharp stylus. The roughness of the measured surface is measured. At this time, the roughness of the measured surface of the workpiece causes the stylus to move. This displacement changes the inductance of the sensor inductor coil, which is proportional to the measured surface roughness at the output end of the phase-sensitive rectifier. The analog signal enters the data acquisition system after amplification and level conversion.

Steps

Dutch TQC DC9000 hull surface roughness measuring instrument This instrument can be operated with one hand, and the operation is displayed on an intuitive illuminated menu by gently pushing the dial switch. The hand strap is available to the user when needed. The sensor is compact and equipped with a set of LED indicators. Due to inconvenience during operation, it may not be possible to observe the control unit. When needed, the sensor can be quickly attached to the operator via an emergency device.

Take you into the Dutch TQC

- 1On surface roughness Measuring method Optical inspection, Mechanical, Atomic Force Microscope (AFM)

- 1GB/T 45767-2025《Silicon nitride ceramic subtrates》

- 2JJF 1105-2018《Calibration Specification for Contact(Stylus)Instruments of Surface Roughness Measurement by Profile Method》

- 3JJG 2018-1989《Measuring Instruments for Surface Roughness》

- 4GB/T 28210-2024《Thermal-sensitive paper》

- 5HB 6172-1988《General surface roughness》

- 6GB/T 42671-2023《Test method for surface roughness of carbon materials》

- 7JJG (轻工) 52-2000《Verification Regulation of Roughness Tester for Paper and Board》

- 8GB/T 13288.2-2011《Preparation of steel substrates before application of paints and related products - Surface roughness characteristics of blast-cleaned substrates - Part 2: Method for the grading of surface profile of abrasive blast-cleaned steel - Comparator procedure》

- 9GB/T 6060.5-1988《Metal asperity comparison specimens, shot throwing (spraying), sand blasting machined surfaces (neq ISO 3632-II: 1985)》

DC9000

DC9000