YD-1000C Leeb Hardness Tester

KODIN YD-1000C Leeb Hardness TesterSPEC

KODIN YD-1000C Leeb Hardness TesterDetails

KODIN YD-1000C Leeb Hardness TesterPacking list

- SKU

- NB003121

- Operating temperature

- 0~40℃

- Power Supply

- 4.7V~6.0V

- Measurement direction

- Five kinds

- Machine Weight

- 0.67Kg (Standard: Hardness Tester + Type D Impact Device)

- Dimensions

- 268*86*47mm

Overview of YD-1000C Leeb Hardness Tester

YD-1000C Leeb Hardness Tester is a new type of handheld, multi-functional dynamic hardness testing instrument, which is designed with professional microprocessor technology.

YD-1000C Leeb Hardness Tester has the characteristics of high test accuracy, stable and reliable performance, small size, easy operation, easy to carry, wide measurement range, etc., which is suitable for rapid hardness testing of metal materials, especially suitable for on-site hardness testing of large parts and non-detachable parts. It can automatically convert the measured Leeb value into Brinell, Rockwell, Vickers, Shore and other hardness values according to different materials and directions and print records, which is a more satisfactory hardness testing instrument.

Product performance

1. Main Applications:

Hardness testing of products in mass production.

On-site hardness testing of mechanical or permanently assembled components after installation.

Hardness testing of heavy workpieces.

Hardness testing of mechanical parts in confined spaces.

Failure analysis of equipment.

Warehouse metal material division.

Hardness control testing of annealing, tempering, quenching and other heat treatments.

2. Main technical parameters

Measurement accuracy: In the same measurement range, the average measurement error of multiple test values is not greater than ±0.8% (relative to the range of 800±50HL). When it is automatically converted to Brinell (HB), Rockwell (HRC, HRB) and Vickers (HV) hardness values, the measurement error is ±3%~±12.5%, and when converted to Shore (HSD) hardness values, the measurement error is ±1.5%~±4.5%.

Operating temperature: 0~40°C

Working Voltage: 4.7V~6.0V

Test directions: five

Weight: 0.67kg (standard configuration: Hardness Tester + D-type impact device)

Dimensions: 268×86×47mm

Working time of one charge: about 8~24 hours

3. Main Functions

Backlighting can be turned on or off at any time during the test;

The test date can be preset by the keyboard;

The test direction and test material can be selected by the keyboard;

It can be equipped with 5 different types of impact devices (D, DC, D+15, C, G);

It can realize the mutual conversion between six hardness (HL, HRC, HRB, HB, HV, HSD) and the mutual conversion between hardness and tensile strength;

Print an unlimited number of test results and remove gross errors;

Full screen display of the current test status and test value;

After shutting down, it can remember the previous set of test results and all preset parameters;

Automatically display the battery Voltage, when the working Voltage is lower than the rated value, the screen character flashes alarm.

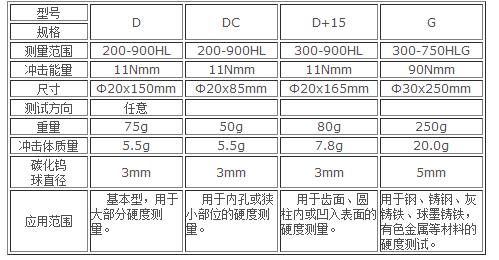

4. Impact device

This Hardness Tester can be equipped with 5 different impact devices, of which type D is the basic type,

The remaining 4 can be applied to hardness testing in special occasions.

Impact device D: used for most hardness tests.

Impact device DC: used for hardness testing in very cramped places (in the hole, in the cylindrical cylinder).

Impact device D+15: used for surface hardness testing in grooves or recesses.

Impact device C: It is used for hardness testing of hardened parts, surface coverings, and thin walls.

Impact device G: Only used for hardness testing of dense parts in the range of Brinell hardness 650HB.

5. Parameters of impact device:

YD-Model 1000C Leeb Hardness Tester configuration sheet

1. 1 YD-1000C host

2. 1 standard Leeb hardness block

3. 1 D-type impact device

4. 1 bottle of adhesive

5. 1 charger

6. 1 small positioning cap and 1 brush

YD-1000C

YD-1000C