HTechMT CO600N1S Coating Thickness Gauge eddy Current 1600μm

HTechMT Thickness Gauge probe CO600N1S thickness measurement range 1600 μm, accuracy +/- 1~ 3% or 2.5 μm, minimum headroom height 80mm, test radius 5mm, substrate thickness minimum 0.8mm, CO600F2H is a common eddy Current thickness probe.

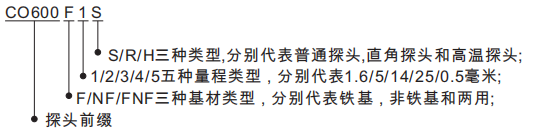

Model:

HTechMT

HTechMT CO600N1S Coating Thickness GaugeSPEC

HTechMT CO600N1S Coating Thickness GaugeDetails

HTechMT CO600N1S Coating Thickness GaugePacking list

- SKU

- NB031260

- Measurement principle

- Eddy Current

- Measurement range

- 1600μm

- margin of error

- ±1~3%/2.5μm

- thinnest substrate

- 0.8mm

- Test environment

- Nonmagnetic metal substrate

- probe

- Ordinary probe

- Minimum headroom

- 80mm

- Minimum measurement surface

- R5mm

- Probe contact surface diameter

- 9mm

CO600N1S

Coating Thickness Gauge

The Thickness Gauge probe core is made of super wear-resistant materials, which greatly improves the service life of the probe and ensures the measurement accuracy and repeatability of the instrument. This design reverses the common defects in the market, such as inaccurate measurement due to core wear, or falling off the inlaid rubera.

Probe number

Executive Standards:ISO 2178/2360/2808、ISO 19840、ASTM B244/B499/D1186/D1400

Probe selection

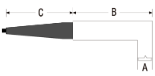

| shape | Probe model | A | B | C | Range | Accuracy 1 | Minimum headroom | Minimum test radius | Minimum substrate thickness |

| CO600F1S | 9 | 40 | 50 | 1.6mm | ± 1-3% or 2.5μm | 80mm | 5mm | 0.8mm |

| CO600F2S | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 80mm | 5mm | 0.8mm | |

| CO600F5S | 9 | 40 | 50 | 0.5mm | ± 1-3% or 2.0μm | 80mm | 5mm | 0.8mm | |

| CO600F1H | 9 | 40 | 50 | 1.6mm | ± 1-3% or 2.5μm | 80mm | 5mm | 0.8mm | |

| CO600F2H | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 80mm | 5mm | 0.8mm | |

| CO600N1S | 9 | 40 | 50 | 1.6mm | ± 1-3% or 2.5μm | 80mm | 5mm | 0.3mm | |

| CO600N2S | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 80mm | 5mm | 0.3mm | |

| CO600N5S | 9 | 40 | 50 | 0.5mm | ± 1-3% or 2.0μm | 80mm | 5mm | 0.3mm | |

| CO600F1R | 9 | 40 | 50 | 1.6mm | ± 1-3% or 2.5μm | 30mm | 5mm | 0.8mm |

| CO600F2R | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 30mm | 5mm | 0.8mm | |

| CO600N1R | 9 | 40 | 50 | 1.5mm | ± 1-3% or 2.5μm | 30mm | 5mm | 0.3mm | |

| CO600N2R | 9 | 40 | 50 | 5.0mm | ± 1-3% or 20μm | 30mm | 5mm | 0.3mm | |

| CO600F3S | 16.5 | 40 | 50 | 13.0mm | ± 1-3% or 50μm | 80mm | 10mm | 1.0mm |

| CO600F4S | 24 | 60 | 50 | 26.0mm | ± 1-3% or 100μm | 120mm | 30mm | 1.0mm |

*High temperature probe temperature is 250°C

FAQ

QIs the price listed on the website the final cost for overseas purchases?

ANo, it isn't. This is the ex-factory price of the product in the Chinese Mainland. In addition to this price, buyers from different countries need to account for additional costs such as shipping fees, tariffs, and others. For specific regional quotes, please consult our customer service or fill out a quotation form.

QWhat is the specific process for purchasing the product?

AFirst, please click on the quotation form on the website and fill in detailed information. Our customer service personnel will then send you a quotation based on your specific country and region, confirming payment and delivery methods. Following this, we proceed with contract signing, payment, and shipment. You can then await delivery.

QWhat should I do if the instrument I purchase needs repair?

AAfter-sales repair for overseas instruments is an unavoidable issue. Our repair terms stipulate that the sender is responsible for the shipping and insurance costs incurred for the repair. Repairs within the warranty period are free, while repair costs beyond the warranty period are determined based on the actual situation.

Standard

CO600N1S

CO600N1S