OSP 22um φ 10mm L500mm production wire-wound drawdown Bar Total length 50cm surface Eletroplating

SEOSP 22um Φ10mm L500mm coating rodSPEC

OSP 22um Φ10mm L500mm coating rodDetails

OSP 22um Φ10mm L500mm coating rodPacking list

- SKU

- NB031325

- WFT

- 22pm

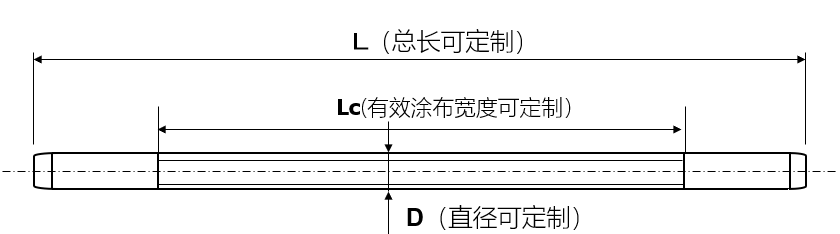

- Total length

- 500mm

- Effective Application Width

- 500mm

- Rod diameter

- 10mm

- Surface process

- chrome plating

- Production process

- Extrusion process

- material

- 304 stainless steel

Advantages of D-Bar

Customers who use traditional wire scrapers often encounter various problems.

①The steel wire is loose and broken

② Difficult to clean and easy to block

③The surface shape cannot be changed freely

Is there any product that can replace the wire scraper? After several improvements, D-BAR was finally successfully developed. It was officially launched into the market in 2001.

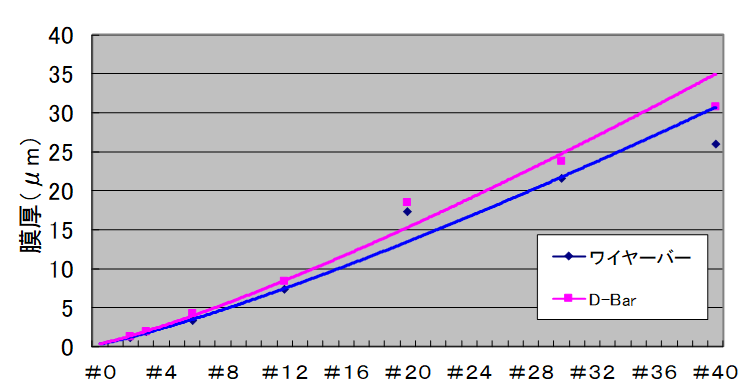

D-Bar can control the wet film thickness as low as 1.5μm for ultra-thin coating

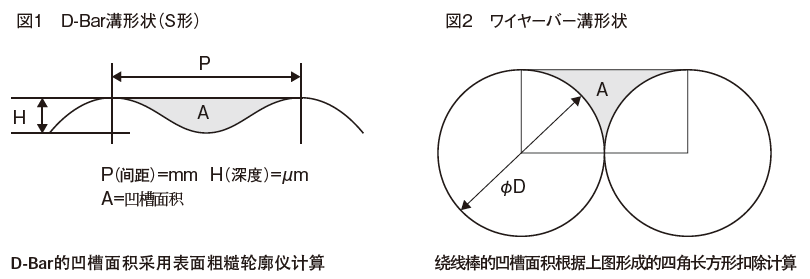

Comparison of Coating Amount of Wire-wound Rod and D-Bar

Difference in coat weight: D-Bar groove bottom is wider than traditional wire bar, so in general, D-Bar coat weight is higher.

D-Bar Coating Rod Specifications

D-Bar specification and length can be customized, please consult NBCHAO customer service for details

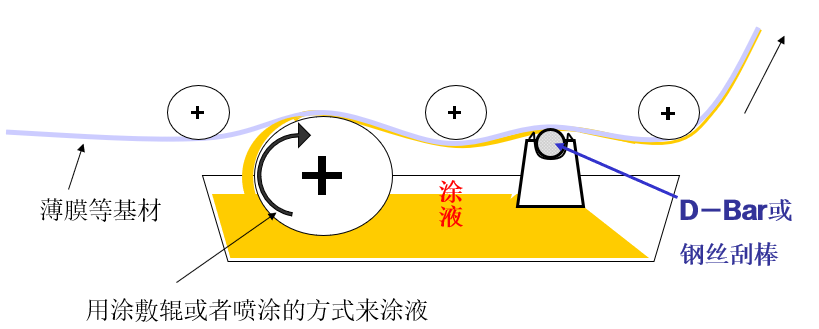

Instructions

When applying liquid on the surface of the substrate, use the DBar to adjust (scrape off) the amount of liquid.

Application

The D-Bar series of extruded production coating rods produced by Japan OSP are widely used in the following industries:

Film: liquid crystal film, X-ray film, packaging film, etc.

Glass: automotive glass, liquid crystal glass, architectural glass, etc.

Paper: newspaper, glossy paper, wallpaper, special paper, etc.

Packaging materials: cartons, tapes, wrapping paper, etc.

Tape: Video tape, etc.

Magnetic card: ticket, recharge card, etc.

22um Φ10mm L500mm

22um Φ10mm L500mm